Stratasys to Test 3D-Printed Material Performance on Moon

Ground testing suggests potential for 50 percent radiation dose reduction

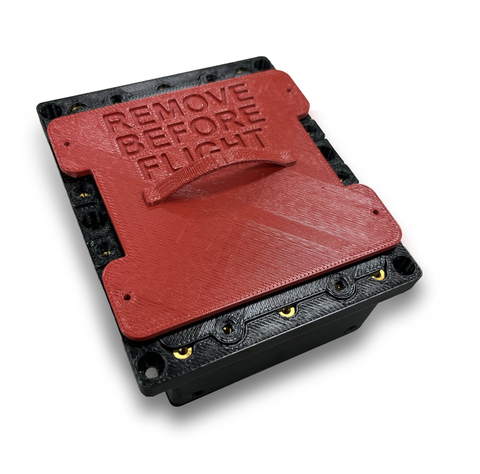

FDM Antero 840CN03 radiation experiment housing with red UTLEM 9085 “Remove Before Flight” cover to protect the test samples during transport and installation. (Photo: Business Wire)

In this moon mission, Stratasys will provide 3D-printed samples that will be brought to the lunar surface by an unmanned lander in a carrier structure 3D-printed by Stratasys. Three materials will be the focus of two different experiments led by Northrop Grumman.

The first experiment assesses the performance of a sample coupon part made with Stratasys’ Antero® 800NA FDM® filament filled with tungsten. Antero 800NA is a high-performance PEKK-based thermoplastic with excellent mechanical properties, chemical resistance, and low outgassing characteristics. Adding tungsten is intended to provide shielding against harmful radiation such as gamma rays or x-rays.

The second passive experiment is designed to see how 3D-printed materials perform in space. It will include Antero 840CN03 FDM filament, which features ESD properties for use with electronics and was used on the Orion spacecraft. The experiment will also include a new ESD photopolymer manufactured by Stratasys partner Henkel for use with Stratasys’ Origin® One 3D printers and designed for high-heat environments. This experiment will subject coupon samples of the 3D-printed materials to moon dust, low pressure that can lead to outgassing, and the rapid temperature swings that result from virtually no atmosphere on the moon.

“Additive manufacturing is an important technology for space missions where every ounce of weight matters and high performance is essential,” said Chief Industrial Business Officer Rich Garrity. “This set of experiments will help us understand how to fully leverage 3D printing to keep people and equipment safe as we travel to the moon and beyond.”

Parts will be brought to the lunar surface by an unmanned lander in a Stratasys 3D printed carrier structure made from ULTEM™ 9085 thermoplastic, which is a material also commonly used in commercial aircraft interiors.

About Stratasys

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, Twitter, LinkedIn, or Facebook. Stratasys reserves the right to utilize any of the foregoing social media platforms, including Stratasys’ websites, to share material, non-public information pursuant to the SEC’s Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

Stratasys, Antero, and FDM are trademarks or registered trademarks of Stratasys Ltd. and/or its affiliates. 9085 and ULTEM trademarks are used under license from SABIC, its affiliate or subsidiary. All other trademarks are the property of their respective owners, and Stratasys assumes no responsibility with regard to the selection, performance, or use of these non-Stratasys products.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240312064089/en/

Investor and Media Contacts

Stratasys Corporate &

Chris Reese

Chris.reese@stratasys.com

+1 651-357-0877

Stratasys Corporate &

Erik Snider

Erik.Snider@stratasys.com

+972 52 400 9610

Jonathan Wake / Samantha White,

Incus Media

stratasys@incus-media.com

+44 1737 215200

Erica Massini

erica.massini@stratasys.com

+55 (11) 2626-9229

Investor Relations

Yonah Lloyd

yonah.lloyd@stratasys.com

+972-74-745-4919

Source: Stratasys Ltd.