Desktop Metal Announces Upgrades to its Popular Live Sinter™ Software, a Powerful Multi-Physics Simulation Tool that Delivers Trusted Results

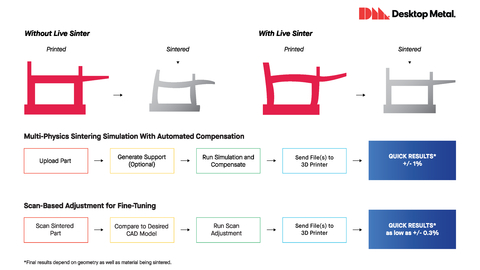

Desktop Metal, a leader in additive manufacturing, announces significant updates to its Live Sinter software, now utilized by over a hundred binder jet 3D printer companies worldwide. This advanced multi-physics simulation software delivers sinter-ready geometries in as little as 20 minutes, ensuring high precision in metal part production. Features include scan-based adjustments for enhanced accuracy and automated generation of supports and setters, streamlining production processes. Live Sinter is pivotal for high-density metal production, aiding in mitigating common sintering challenges.

- Live Sinter software used by over 100 companies worldwide.

- Delivers sinter-ready geometries in as little as 20 minutes.

- Enables corrections for distortion to achieve parts within 1% of target dimensions.

- Automates generation of sintering supports and setters, reducing costs.

- Critical for the success of Desktop Metal's Shop System, the best-selling metal binder jet printer.

- None.

-

Powerful multi-physics sintering simulation software is now trusted by users at more than a hundred

Desktop Metal binder jet 3D printer companies globally - Simulation software predicts and corrects for shrinkage and distortion in part designs in as little as 20 minutes, delivering sinter-ready, printable geometries

- Now with scan-based adjustments, Live Sinter allows users to fine tune their simulation results based on one or multiple scans to further dial in part accuracies

- Live Sinter also automates the generation of live, metal sintering supports or ceramic sintering setters, including floating setter inserts

- By combining sintering simulation with scan-based adjustments and easy-to-use automated corrective tools, Live Sinter remains a unique tool for optimizing metal binder jetting parts production

Live Sinter simulation software predicts and corrects for shrinkage and distortion in metal parts 3D printed with binder jetting technology. Sinter-ready, printable geometries are provided in as little as 20 minutes and deliver highly accurate final part results. (Graphic: Business Wire)

Launched in the fall of 2020, Live Sinter is now trusted by users at more than a hundred companies globally, and the software is a key enabler of Desktop Metal’s AM 2.0 binder jetting solutions, making them easier to adopt and ramp to production for customers without any prior powder metallurgy or sintering expertise.

Live Sinter’s powerful multi-physics simulation and compensation software delivers sinter-ready, printable geometries that maintain tight shape and dimensional tolerances. After scan-based adjustments, Live Sinter enables correcting for complex distortion effects, yielding parts that consistently fall well within

“Within the field of sinter-based additive manufacturing, Live Sinter stands alone for its ease of use and functionality,” said

A Key to Metal Printing Success

Live Sinter is a critical companion to Desktop Metal’s portfolio of metal binder jetting systems, which produce parts that must be sintered in a furnace to fuse the particles into a high-density material.

The Shop System is now the world’s best-selling metal binder jet printer, and Live Sinter has been a critical component of that turnkey printer’s ease of use and success.

“One of my biggest worries investing in this technology was the furnace and the frustration of failing that far into the process during sintering. Using Live Sinter, I’m blown away at our success with the sintering furnace,” said

“We’ve found Live Sinter to be an extremely valuable tool for FreeFORM. The ability to print, scan, adjust, reprint, etcetera, has reduced our lead time by helping us yield product in spec faster than a traditional trial and error loop. The ability of the software to predictively deform products prior to first manufacturing or to take first-off parts and make adjustments have resulted in our customers getting to market faster with product so they can move on to their next development,” said

To learn more about Live Sinter, visit https://www.desktopmetal.com/products/livesinter

About

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in

View source version on businesswire.com: https://www.businesswire.com/news/home/20220830005300/en/

Media Relations:

(724) 516-2336

Sarahwebster@desktopmetal.com

Investor Relations:

(781) 730-2110

jaygentzkow@desktopmetal.com

Source:

FAQ

What updates has Desktop Metal announced for Live Sinter software?

How does Live Sinter improve 3D metal printing?

How quickly can Live Sinter deliver sinter-ready geometries?

What is the significance of desktop metal's Live Sinter software?