PFAS Destruction Testing Confirms That PyroGenesis’ Plasma Torches Reduce Energy Requirements By Up To 45%

PyroGenesis (TSX: PYR, OTCQX: PYRGF) announces significant energy efficiency achievements in their plasma torch technology. Recent testing data confirms up to 45% reduction in operational energy requirements compared to legacy diesel burners in PFAS destruction applications.

Tests across various applications demonstrate consistent benefits:

- 10-45% reduction in global energy consumption in aluminum sector applications

- Up to 30% reduction in melting time, increasing productivity

- 80% energy reduction in casting ladle heating compared to natural gas burners

These improvements enable companies to build smaller equipment for the same capacity, reduce costs, and increase production levels. The technology is part of PyroGenesis' three-vertical solution ecosystem, focusing on Energy Transition and Emission Reduction, Waste Remediation, and Commodity Security and Optimization.

PyroGenesis (TSX: PYR, OTCQX: PYRGF) annuncia importanti risultati in termini di efficienza energetica nella loro tecnologia della torcia a plasma. I dati di recenti test confermano una riduzione fino al 45% dei requisiti energetici operativi rispetto ai bruciatori diesel tradizionali nelle applicazioni di distruzione dei PFAS.

I test in diverse applicazioni mostrano benefici costanti:

- riduzione del 10-45% del consumo energetico globale nelle applicazioni del settore dell'alluminio

- riduzione fino al 30% del tempo di fusione, aumentando la produttività

- riduzione dell'80% dell'energia nel riscaldamento delle pentole di colata rispetto ai bruciatori a gas naturale

Questi miglioramenti consentono alle aziende di costruire attrezzature più piccole per la stessa capacità, ridurre i costi e aumentare i livelli di produzione. La tecnologia è parte dell'ecosistema a tre verticali di PyroGenesis, incentrato sulla Transizione Energetica e Riduzione delle Emissioni, Bonifica dei Rifiuti e Sicurezza e Ottimizzazione delle Merci.

PyroGenesis (TSX: PYR, OTCQX: PYRGF) anuncia logros significativos en eficiencia energética en su tecnología de antorchas de plasma. Los datos de pruebas recientes confirman una reducción de hasta el 45% en los requisitos energéticos operativos en comparación con los quemadores diésel tradicionales en aplicaciones de destrucción de PFAS.

Las pruebas en diversas aplicaciones demuestran beneficios consistentes:

- reducción del 10-45% en el consumo energético global en aplicaciones del sector del aluminio

- reducción de hasta el 30% en el tiempo de fusión, aumentando la productividad

- reducción del 80% de energía en el calentamiento de la olla de fundición en comparación con los quemadores de gas natural

Estas mejoras permiten a las empresas construir equipos más pequeños para la misma capacidad, reducir costos y aumentar los niveles de producción. La tecnología forma parte del ecosistema de solución de tres verticales de PyroGenesis, centrado en la Transición Energética y Reducción de Emisiones, Remediación de Residuos y Seguridad y Optimización de Materias Primas.

PyroGenesis (TSX: PYR, OTCQX: PYRGF)는 그들의 플라즈마 토치 기술에서 상당한 에너지 효율성 달성을 발표했습니다. 최근 테스트 데이터는 PFAS 파괴 응용 프로그램에서 기존 디젤 버너에 비해 운영 에너지 요구 사항이 최대 45% 감소했음을 확인합니다.

다양한 응용 프로그램에서의 테스트는 일관된 이점을 보여줍니다:

- 알루미늄 산업 응용 프로그램에서 전 세계 에너지 소비가 10-45% 감소

- 업무 생산성을 높이며 용융 시간이 최대 30% 단축

- 천연 가스 버너에 비해 주조 리들 가열에서 80% 에너지 절감

이러한 개선 사항들은 기업이 동일한 용량을 위해 더 작은 장비를 제작하고 비용을 줄이며 생산 수준을 높이는 것을 가능하게 합니다. 이 기술은 에너지 전환 및 배출 감소, 폐기물 복원, 원자재 보안 및 최적화에 초점을 맞춘 PyroGenesis의 세 가지 수직 솔루션 생태계의 일부입니다.

PyroGenesis (TSX: PYR, OTCQX: PYRGF) annonce des réalisations significatives en matière d'efficacité énergétique dans sa technologie de torche à plasma. Les données des tests récents confirment une réduction allant jusqu'à 45% des besoins énergétiques opérationnels par rapport aux brûleurs à diesel traditionnels dans les applications de destruction des PFAS.

Les tests réalisés dans diverses applications montrent des avantages constants :

- réduction de 10 à 45% de la consommation globale d'énergie dans les applications du secteur de l'aluminium

- réduction de jusqu'à 30% du temps de fusion, augmentant la productivité

- réduction de 80% de l'énergie pour le chauffage des chaudrons de coulée par rapport aux brûleurs à gaz naturel

Ces améliorations permettent aux entreprises de construire des équipements plus petits pour la même capacité, de réduire les coûts et d'augmenter les niveaux de production. La technologie fait partie de l'écosystème de solutions à trois volets de PyroGenesis, axé sur la transition énergétique et la réduction des émissions, la réhabilitation des déchets, et la sécurité et l'optimisation des matières premières.

PyroGenesis (TSX: PYR, OTCQX: PYRGF) gibt bedeutende Erfolge in der Energieeffizienz ihrer Plasmaplanentechnologie bekannt. Aktuelle Testdaten bestätigen eine Reduzierung des Betriebsenergiebedarfs um bis zu 45% im Vergleich zu herkömmlichen Dieselbrennern in Anwendungen zur Zerstörung von PFAS.

Tests in verschiedenen Anwendungen zeigen konsistente Vorteile:

- 10-45% Reduzierung des globalen Energieverbrauchs in Aluminiumsektoranwendungen

- Bis zu 30% Reduzierung der Schmelzzeit, wodurch die Produktivität steigt

- 80% Energieeinsparung beim Heizen von Gießpfannen im Vergleich zu Erdgasbrennern

Diese Verbesserungen ermöglichen es Unternehmen, kleinere Geräte mit der gleichen Kapazität zu bauen, Kosten zu senken und Produktionsniveaus zu steigern. Die Technologie ist Teil des dreisäuligen Lösungssystems von PyroGenesis, das sich auf Energiewende und Emissionsreduzierung, Abfallbeseitigung sowie Rohstoffsicherheit und -optimierung konzentriert.

- Up to 45% reduction in operational energy requirements compared to diesel burners

- 30% reduction in melting time, leading to higher productivity

- 80% energy reduction in casting ladle heating versus natural gas burners

- Potential for smaller equipment footprint while maintaining capacity

- Increased production capability from same production footprint

- None.

Supports recent results from other projects using PyroGenesis plasma torches showing lower energy usage, reduced CAPEX, and faster production rates.

MONTREAL, Feb. 10, 2025 (GLOBE NEWSWIRE) -- PyroGenesis Inc. (“PyroGenesis”) (http://pyrogenesis.com) (TSX: PYR) (OTCQX: PYRGF) (FRA: 8PY), a high-tech company that designs, develops, manufactures and commercializes advanced all-electric plasma processes and sustainable solutions to support heavy industry in their energy transition, emission reduction, commodity security, and waste remediation efforts, announces that recent data from a current contract confirms that PyroGenesis plasma torches posted significantly lower operational energy requirements. Savings of up to

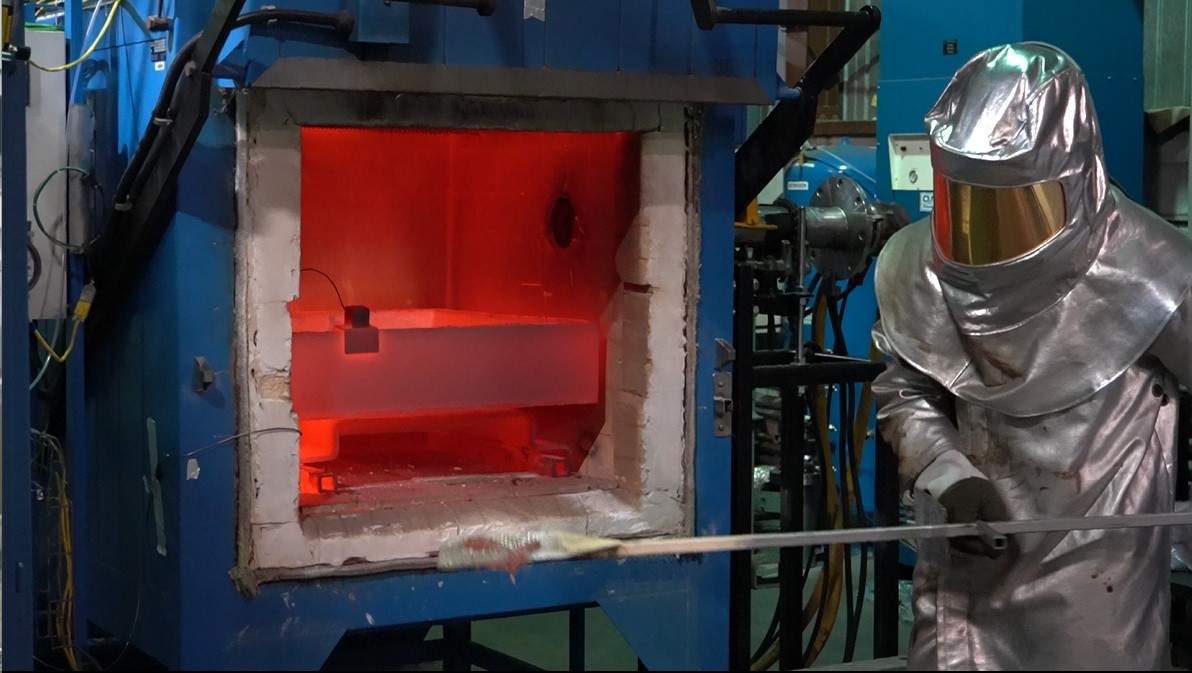

Figure 1: An engineer removes metal from a furnace during PyroGenesis' tests using plasma torches within an aluminum melting furnace supplied by its client Constellium.

These latest results are consistent with those obtained in other test installations where PyroGenesis plasma torches were used. In controlled tests carried out by PyroGenesis for similar applications in the aluminum sector, including those conducted as part of a contract with Constellium, one of the world’s largest aluminum transformation and recycling companies (press release dated April 10, 2024), to benchmark plasma torches against equivalent-power fossil-fuel burners, PyroGenesis’ plasma torches have achieved improvements of up to

Separately, tests using PyroGenesis plasma torches in casting ladle heating demonstrated energy reduction of

“These latest results, which have been confirmed across several projects under very different conditions, have significant implications for our torch offerings,” said P. Peter Pascali, President and CEO of PyroGenesis. “First, a solid business case can be made to transition to all-electric PyroGenesis plasma torches from an energy savings perspective alone, and any positive environmental impact (such as CO2 reduction) would be just icing on the cake. Second, with the reduced energy requirement as a result of using PyroGenesis torches, companies can now contemplate building smaller equipment (for the same capacity), reducing costs further for the same project. Third, the reduced aluminum melting time means companies can raise production levels, generating higher and faster output. Increasing production rates by up to

PyroGenesis’ development of plasma torches for use in high temperature industrial processes is part of its three-vertical solution ecosystem that aligns with economic drivers that are key to global heavy industry. Plasma torches for use in industrial furnaces are part of PyroGenesis’ Energy Transition and Emission Reduction vertical, where fuel switching to PyroGenesis’ electric-powered plasma torches helps heavy industry reduce energy costs, fossil fuel use, and emissions. The other verticals are Waste Remediation and Commodity Security and Optimization.

About PyroGenesis Inc.

PyroGenesis, a high-tech company, is a proud leader in the design, development, manufacture and commercialization of advanced plasma processes and sustainable solutions which reduce greenhouse gases (GHG) and are economically attractive alternatives to conventional “dirty” processes. PyroGenesis has created proprietary, patented and advanced plasma technologies that are being vetted and adopted by multiple multibillion dollar industry leaders in four massive markets: iron ore pelletization, aluminum, waste management, and additive manufacturing. With a team of experienced engineers, scientists and technicians working out of its Montreal office, and its 3,800 m2 and 2,940 m2 manufacturing facilities, PyroGenesis maintains its competitive advantage by remaining at the forefront of technology development and commercialization. The operations are ISO 9001:2015 and AS9100D certified, having been ISO certified since 1997. PyroGenesis’ shares are publicly traded on the TSX in Canada (TSX: PYR), the OTCQX in the US (OTCQX: PYRGF), and the Frankfurt Stock Exchange in Germany (FRA: 8PY).

Cautionary and Forward-Looking Statements

This press release contains “forward-looking information” and “forward-looking statements” (collectively, “forward-looking statements”) within the meaning of applicable securities laws. In some cases, but not necessarily in all cases, forward-looking statements can be identified by the use of forward-looking terminology such as “plans”, “targets”, “expects” or “does not expect”, “is expected”, “an opportunity exists”, “is positioned”, “estimates”, “intends”, “assumes”, “anticipates” or “does not anticipate” or “believes”, or variations of such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “might”, “will” or “will be taken”, “occur” or “be achieved”. In addition, any statements that refer to expectations, projections or other characterizations of future events or circumstances contain forward-looking statements. Forward-looking statements are not historical facts, nor guarantees or assurances of future performance but instead represent management’s current beliefs, expectations, estimates and projections regarding future events and operating performance.

Forward-looking statements are necessarily based on a number of opinions, assumptions and estimates that, while considered reasonable by PyroGenesis as of the date of this release, are subject to inherent uncertainties, risks and changes in circumstances that may differ materially from those contemplated by the forward-looking statements. Important factors that could cause actual results to differ, possibly materially, from those indicated by the forward-looking statements include, but are not limited to, the risk factors identified under “Risk Factors” in PyroGenesis’ latest annual information form, and in other periodic filings that it has made and may make in the future with the securities commissions or similar regulatory authorities, all of which are available under PyroGenesis’ profile on SEDAR+ at www.sedarplus.ca. These factors are not intended to represent a complete list of the factors that could affect PyroGenesis. However, such risk factors should be considered carefully. There can be no assurance that such estimates and assumptions will prove to be correct. You should not place undue reliance on forward-looking statements, which speak only as of the date of this release. PyroGenesis undertakes no obligation to publicly update or revise any forward-looking statement, except as required by applicable securities laws.

Neither the Toronto Stock Exchange, its Regulation Services Provider (as that term is defined in the policies of the Toronto Stock Exchange) nor the OTCQX Best Market accepts responsibility for the adequacy or accuracy of this press release.

For further information please contact:

Rodayna Kafal, Vice President, IR/Comms. and Strategic BD

E-mail: ir@pyrogenesis.com

http://www.pyrogenesis.com

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/69d460b5-491e-4cb4-a58a-20ddb13fde42