Electra Produces Lithium from Battery Recycling Trial, Significantly Improving its Project Economics

Electra Battery Materials Corporation (NASDAQ: ELBM; TSX-V: ELBM) announced successful lithium recovery from black mass in its refinery trial near Toronto. This process validates Electra's proprietary hydrometallurgical technique, crucial for the EV battery supply chain. CEO Trent Mell highlighted that this achievement significantly enhances the economics of Electra's recycling strategy and reduces the carbon footprint associated with EV manufacturing. The company aims to commercialize this process and expects domestic demand for recoverable battery materials to rise by 20% annually until 2040.

- Successful recovery of lithium in black mass recycling trial.

- Validates proprietary hydrometallurgical process for EV battery materials.

- Strengthens the economics of Electra's battery recycling strategy.

- Lowers carbon footprint associated with electric vehicle manufacturing.

- Plans to commercialize the lithium recovery process with industry partners.

- None.

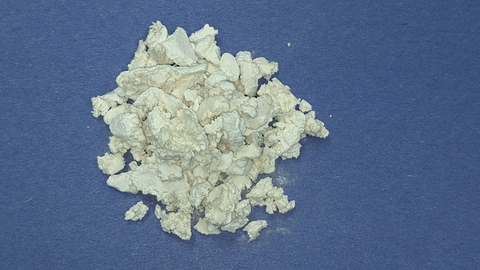

Lithium carbonate produced by Electra in its black mass recycling trial (Photo: Business Wire)

“Recovering lithium from black mass represents a potential game changer for Electra and the North American EV supply chain,” said

“Our refinery team, combined with our consulting engineering partners, achieved a significant milestone in proving up our hydrometallurgical process for treating black mass,” said

Black mass is the industry term used to describe the material remaining once expired lithium-ion batteries are shredded and all casings removed. Black mass contains high-value elements, including lithium, nickel, cobalt, manganese, copper, and graphite, that once recovered, can be recycled to produce new lithium-ion batteries.

Established North American battery recyclers have focused on collecting and shredding of batteries with the resulting black mass material primarily treated by a pyrometallurgical smelting process that has a higher carbon footprint and lower metal recoveries than hydrometallurgical processes.

Recycling black mass will increasingly become a key feature of the EV battery supply chain given the strong demand for critical minerals and the looming supply deficit of metals such as nickel and cobalt. According to data from

Electra launched its black mass demonstration plant at the end of

As disclosed previously, Electra has decided to extend its black mass processing and recovery activities through

The total amount of material to be processed and recovered through June will be determined in the coming weeks. The Company has identified multiple sources of supply, and is in discussions on terms and conditions with vendors.

All of Electra’s recovered material will be sold to third-party companies for additional processing and re-use in a number of applications.

About

Electra is a processor of low-carbon, ethically-sourced battery materials. Currently commissioning North America’s only cobalt sulfate refinery, Electra is executing a multipronged strategy focused on onshoring the electric vehicle supply chain. Keys to its strategy are integrating black mass recycling and nickel sulfate production at Electra’s refinery located north of

Neither the

Cautionary Note Regarding Forward-Looking Statements

This news release may contain forward-looking statements and forward-looking information (together, “forward-looking statements”) within the meaning of applicable securities laws and the United States Private Securities Litigation Reform Act of 1995. All statements, other than statements of historical facts, are forward-looking statements. Generally, forward-looking statements can be identified by the use of terminology such as “plans”, “expects', “estimates”, “intends”, “anticipates”, “believes” or variations of such words, or statements that certain actions, events or results “may”, “could”, “would”, “might”, “occur” or “be achieved”. Such forward-looking statements include, without limitation, statements regarding the attributes of the Notes, the closing date of the Note Offering, the listing of the underlying Common Shares and the expected use of proceeds of the Offering. Forward-looking statements involve risks, uncertainties and other factors that could cause actual results, performance, and opportunities to differ materially from those implied by such forward-looking statements. Factors that could cause actual results to differ materially from these forward-looking statements are set forth in the management discussion and analysis and other disclosures of risk factors for

View source version on businesswire.com: https://www.businesswire.com/news/home/20230313005237/en/

info@ElectraBMC.com 1.416.900.3891

Source:

FAQ

What recent achievement did Electra Battery Materials Corporation announce regarding lithium recovery?

How does Electra's lithium recovery process impact electric vehicle manufacturing?

What is the future outlook for battery material recycling according to Electra?

When did Electra launch its black mass demonstration plant?