Desktop Metal to Showcase a Historic Collection of 300+ 3D Printed Production Parts Across the Industry’s Widest Portfolio of Materials at RAPID + TCT in Detroit

Desktop Metal (NYSE:DM) will showcase over 300 3D printed production parts at RAPID + TCT from May 17-19 in Detroit. This marks the first public display of its expanded Team DM portfolio, which includes innovative 3D printing solutions across various materials. Highlights include a hydraulic valve with a 60% weight reduction and the Production System P-1, an advanced 3D printer designed for rapid metal part production. The company aims to support President Biden's AM Forward initiative to enhance local manufacturing through advanced additive technologies.

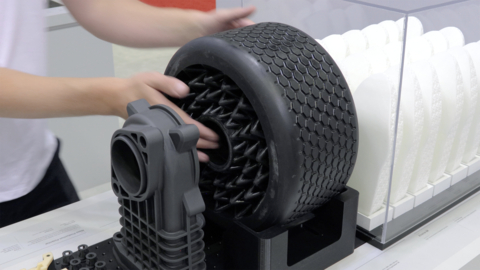

- Showcasing over 300 3D printed production parts at RAPID + TCT.

- Introduction of the expanded Team DM portfolio including diverse materials for 3D printing.

- Highlighting innovations like a hydraulic valve that achieves a 60% weight reduction.

- Demonstration of the Production System P-1, facilitating high-speed 3D printing for metal parts.

- Alignment with President Biden's AM Forward initiative, promoting local manufacturing and modernization.

- None.

-

The collection is the first time

Desktop Metal will display applications across its expanded Team DM portfolio, which now includes metal, polymer, elastomer, ceramic, composite, and upcycled wood 3D printing solutions, following several acquisitions - Application examples in the automotive, aerospace, energy, medical, and consumer goods industries will illustrate the benefits of additive manufacturing, such as speed, part consolidation, lightweighting, and new innovations, including performance improvements

-

One highlight of the collection is a hydraulic valve binder jet printed in steel by Desktop Metal’s Aidro brand, delivering a

60% weight reduction and improved performance - A range of Desktop Metal’s of Additive Manufacturing (AM) 2.0 printer platforms will also be on display at the show, led by the Production System™ P-1 — a gateway printer to the Production System P-50, the world’s fastest system to 3D print metal parts at scale

- Other printing platforms to be on display include the Desktop Metal Shop System™, the ETEC Xtreme 8K photopolymer DLP printer, the Desktop Health Einstein™ printer for dental professionals, and the ExOne S-Max® Flex robotic sand printer for foundries

- Together, Desktop Metal’s parts collection and printers demonstrate how AM 2.0 stands ready to de-risk supply chains with its ability to produce high-quality, cost-competitive end parts and tooling on demand, while delivering sustainability and innovation benefits

Desktop Metal’s parts and printer collection, which will greet attendees in Booth No. 3301 at the main entrance of the show, demonstrates how the AM industry stands ready to deliver on President Joe Biden’s recently announced AM Forward initiative to accelerate the adoption of industrial 3D printing. Biden spoke in detail

“3D printing technology is incredible. It can reduce the parts lead times by as much as 90 percent …,” Biden said. “That all helps to lower the cost of making goods here in America. … These technologies revolutionize the way of life; they keep prices low for businesses and families. So, let’s make them in America again. Let’s build the future here in America.”

As a global industry leader in AM, Desktop Metal’s mission is to enable production 3D printing with accessible AM 2.0 technologies so companies of all sizes can deliver more advanced parts and products faster, while also producing more sustainably and closer to the point of end use.

Desktop Metal’s new portfolio of Team DM brands was carefully curated over the past year to deliver on this mission. By pairing 3D printing technologies that are truly production-capable – such as binder jetting and digital light processing – with high-performance materials and select applications, the

“The COVID pandemic has exposed the weaknesses of our current manufacturing infrastructure, and we applaud the

Production 3D Printing on Display at RAPID + TCT

While

A high-speed 3D printing system for end-use metal parts, the P-1 was designed as a gateway to the top-of-the-line Production System P-50 – the world’s fastest system to 3D print metal parts at scale. The P-1 shares the same patent-pending Single Pass Jetting™ (SPJ) technology as the P-50, as well as common software and electronics for easy scalability.

The P-1 is now being used for a variety of development and serial production applications by a growing number of customers worldwide, including Ford Motor Co., Indo-MIM, Formula 3D Corporation,

Two new videos released today showcase small manufacturers using the technology for production today – including FreeFORM Technologies, a metal parts manufacturing startup in

The Production System is one of several

Nearly a dozen metals are now qualified for printing on the Production System P-1 and P-50 – delivering excellent part quality and surface finish, with sintered part mechanical properties that meet or exceed applicable industry standards, and final part densities up to or exceeding 99 percent. To date, the list of qualified materials includes:

- Stainless steels, including 17-4 PH, 316L, 420, 440C, and DM HH SS

- Tool steels, including D2 and S7

- Low-alloy steels, including 4140

- Copper alloys

- Nickel superalloys, including IN625

- Precious metals, including silver and gold

- Ti64 and 6061 in development

For more information, visit www.desktopmetal.com.

About

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks and uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in

View source version on businesswire.com: https://www.businesswire.com/news/home/20220511005615/en/

Media Relations:

lyndamckinney@desktopmetal.com

(978) 224-1282

Investor Relations:

jaygentzkow@desktopmetal.com

(781) 730-2110

Source: