Desktop Metal Releases Live Inspect™ Tolerance Analysis and Scan Adjustment Software for Additively Manufactured Parts

- Live Inspect is a solution for users of various additive manufacturing technologies to fine-tune accuracy by analyzing 3D scans of printed parts to provide tolerance analysis and correct for deviations

- Part of Desktop Metal’s Live Suite package of software programs that seamlessly manage 3D printers, accessories, and processes, Live Inspect can correct for any type of repeatable AM defect across 3D printing platforms

- Live Inspect is available as an added featured to Live Sinter sintering simulation and compensation software for users of metal binder jet 3D printing — or as a standalone version for users of other systems and technologies

-

Live Inspect will be on display June 25-27 in

Los Angeles at Rapid + TCT, North America’s largest additive manufacturing and industrial 3D printing event

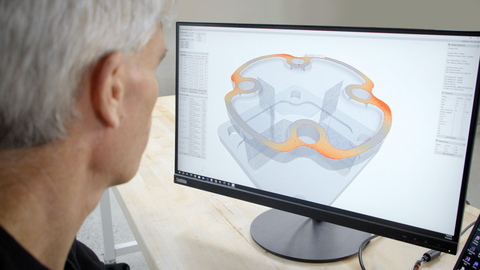

Part of Desktop Metal’s Live Suite package of software programs that seamlessly manage 3D printers, accessories, and processes, Live Inspect can correct for any type of repeatable AM defect across 3D printing platforms. (Photo: Business Wire)

Part of Desktop Metal’s Live Suite software portfolio, Live Inspect allows manufacturers to dial in accuracy and 3D print parts that hit higher tolerances. The software analyzes features on a 3D scan — such as holes, slots, and planar surfaces — and provides tolerance analysis according to standard geometric dimensioning and tolerancing (GD&T) norms and practices. Live Inspect then automatically applies feature-level scan adjustments that correct for deviations identified by the tolerance-based scan analysis.

Many users of additive technologies use 3D scanners to verify part tolerances. While some tools provide an analysis of these scans, Live Inspect both analyzes and corrects for 3D printing variations.

“Our team developed Live Inspect with the goal of delivering 3D printed results as true to CAD designs as possible,” said Ric Fulop, Desktop Metal Co-Founder and CEO. “This solution can affect how compensation is applied to 3D scans through user-identified datums that allows them to fine tune prints and hit higher tolerances in production.”

For users of Team DM binder jetting platforms, Live Inspect enhances the capabilities of Live Sinter, Desktop Metal’s revolutionary sintering simulation and compensation software.

However, Live Inspect is not just a solution for powder metal shrinkage and distortion due to density variations, gravity, and friction during sintering, but can also aid in the manufacturing of polymer parts that experience warping due to curing and thermal effects or sandcasting cores swelling due to microwave curing. The software will be available as an added feature bundled with Live Sinter for metal binder jetting operators as well as a stand-alone option for users of other platforms and additive technologies.

Live Inspect will be introduced as part of Desktop Metal’s display at Rapid + TCT in

For more information on the Desktop Metal Live Inspect software visit TeamDM.com/LiveInspect

About Desktop Metal

Desktop Metal (NYSE:DM) is driving Additive Manufacturing 2.0, a new era of on-demand, digital mass production of industrial, medical, and consumer products. Our innovative 3D printers, materials, and software deliver the speed, cost, and part quality required for this transformation. We’re the original inventors and world leaders of the 3D printing methods we believe will empower this shift, binder jetting and digital light processing. Today, our systems print metal, polymer, sand and other ceramics, as well as foam and recycled wood. Manufacturers use our technology worldwide to save time and money, reduce waste, increase flexibility, and produce designs that solve the world’s toughest problems and enable once-impossible innovations. Learn more about Desktop Metal and our #TeamDM brands at www.desktopmetal.com.

Forward-looking Statements

This press release contains forward-looking statements within the meaning of the federal securities laws. All statements other than statements of historical facts contained in these communications, including statements regarding Desktop Metal’s future results of operations and financial position, financial targets, business strategy, and plans and objectives for future operations, are forward-looking statements. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks and uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to: risks associated with the integration of the business and operations of acquired businesses; Desktop Metal’s ability to realize the benefits from cost saving measures; supply and logistics disruptions, including shortages and delays. For more information about risks and uncertainties that may impact Desktop Metal’s business, financial condition, results of operations and prospects generally, please refer to Desktop Metal’s reports filed with the SEC, including without limitation the “Risk Factors” and/or other information included in the Form 10-Q filed with the SEC on August 3, 2023, and such other reports as Desktop Metal has filed or may file with the SEC from time to time. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240618758323/en/

Investor Relations:

(857) 504-1084

DesktopMetalIR@icrinc.com

Media Relations:

Sarah

(313) 715-6988

sarahwebster@desktopmetal.com

Source: Desktop Metal