Desktop Metal Launches D2 Tool Steel for Additive Manufacturing With the Studio System 2

Desktop Metal (NYSE: DM) has qualified D2 tool steel for its Studio System™ 2, facilitating a simple two-step process for producing high-performance metal parts. This innovation allows users to manufacture high-strength D2 applications such as cold work metal forming tools and injection molds with ease. D2's properties include high hardness and wear resistance, making it ideal for various applications in manufacturing. The new capabilities aim to enhance affordability and access to advanced 3D printing for businesses.

- Qualification of D2 tool steel for the Studio System 2 enhances product offerings.

- The two-step process simplifies production, improving accessibility and affordability.

- D2 tool steel's attributes include high hardness and wear resistance, critical for many manufacturing applications.

- None.

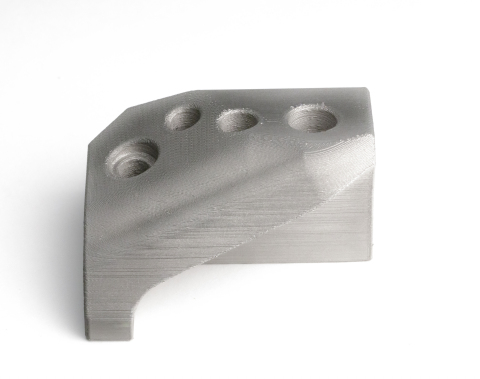

Aerial cam cutting section tools are a component of stamping dies that make frame components on high-volume vehicle manufacturing lines. D2 tool steel is a key material for this application because of its high hardness and excellent wear resistance, properties critical for stamping applications where the tool is subjected to repeated impact while forming. (Photo: Business Wire)

D2 is a versatile high-

“D2 tool steel has traditionally been a challenging and expensive material to work with,” said

With the Studio System 2, D2 tool steel parts demonstrate excellent mechanical properties on a more accessible platform than legacy powder bed fusion 3D printing alternatives. An example of a key use case includes:

- Stamping Tool - Aerial Cam Cutting Section

Aerial cam cutting section tools are a component of stamping dies that make frame components on high-volume vehicle manufacturing lines. D2 tool steel is a key material for this application because of its high hardness and excellent wear resistance, properties critical for stamping applications where the tool is subjected to repeated impact while forming. Stamping tools like these are produced in low volumes, traditionally using advanced machining techniques and slow feed rates because of the material’s high hardness. With the Studio System 2, businesses can now print these tools in D2 at low volumes cost-effectively while reducing complex machining operations, CNC fixturing setups, and CNC tool wear.

“Egar Tool and Die is a rapidly growing manufacturing company for automotive stamping dies, production stampings and welded assemblies and we have been eagerly awaiting the launch of D2 for our two Studio Systems,” said

The Studio System 2 - Office-Friendly Metal 3D Printing

The Studio System 2 is an office-friendly metal additive manufacturing system that leverages Desktop Metal’s proprietary Bound Metal Deposition™ (BMD) technology to produce parts. The easy, two-step process - allowing parts to be transferred directly from the printer into the furnace - provides a nearly hands-free experience, while eliminating loose powders and dangerous lasers commonly associated with metal 3D printing. Consisting of a printer and furnace, the Studio System 2 simplifies in-house low volume production of a wide range of complex geometries with outstanding surface finish and high-performance mechanical properties.

In addition to D2, the Studio System 2 is compatible with Ti64 and 316L stainless steel, as well as all materials previously supported by the Studio System, including 17-4PH stainless steel, 4140 low-alloy steel, H13 tool steel, and copper. A broad portfolio of additional materials that take advantage of the Studio System 2’s streamlined, two-step process is in active R&D with new releases slated to roll out this year.

To learn more about the Studio System 2 and applications for D2, visit www.desktopmetal.com.

About

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in

View source version on businesswire.com: https://www.businesswire.com/news/home/20211207005658/en/

Media Relations:

carolinelegg@desktopmetal.com

(203) 313-4228

Investor Relations:

jaygentzkow@desktopmetal.com

(781) 730-2110

Source:

FAQ

What is D2 tool steel qualified for?

How does the Studio System 2 process work?

What are the applications of D2 tool steel?

What are the benefits of the Studio System 2?