Desktop Metal Introduces All-New Digital Sheet Metal Forming Technology with Figur G15 at IMTS 2022

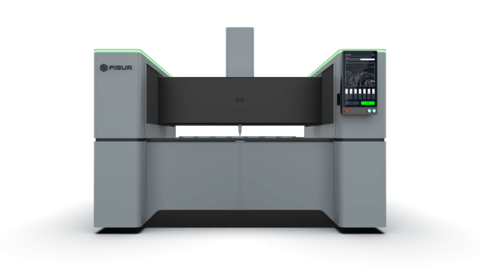

Desktop Metal has launched the Figur G15, a groundbreaking platform using patent-pending Digital Sheet Forming (DSF) technology. This innovation allows manufacturers to create high-quality sheet metal parts directly from digital files, eliminating the need for expensive custom tools, molds, or dies. Capable of shaping materials up to 2.5 mm thick with a forming area of 1450 x 1000 mm, the G15 aims to enhance business agility in the $300 billion sheet metal industry. Live demonstrations will occur at IMTS 2022 in Chicago.

- Launch of Figur G15 utilizing innovative Digital Sheet Forming technology.

- Eliminates need for costly custom tooling, molds, and dies, potentially lowering startup costs.

- Offers quick turnaround for sheet metal parts, enhancing manufacturing flexibility.

- Can process a variety of metals and thicknesses, increasing application scope.

- None.

● The Figur G15 uses patent-pending Digital Sheet Forming (DSF) technology in which a software-driven ceramic toolhead on a gantry shapes standard sheet metal into parts with up to 2,000 lbs of force

● With a maximum sheet size of 1600 x 1200 mm (63.0 x 47.2 in), the Figur G15 delivers parts with a draw depth up to 400 mm (16 in) in Z without custom forming tools, molds, dies, or presses

● The G15 supports forming a range of metals and sheet thicknesses – including steel up to 2.0 mm and aluminum up to 2.5 mm

● Parts produced on the G15 have a high quality surface finish with little to no post-processing required

● Manufacturers now have a competitive way to offer formed sheet metal parts and products quickly without the high startup and development costs normally associated with sheet metal fabrication

● The Figur G15 will be on display at IMTS 2022 in

● Reservations for the Figur G15 are being taken at figur.desktopmetal.com

The Figur G15 uses an all-new Digital Sheet Forming (DSF) technology from

While digital cutting tools are commonly used today and have delivered many benefits to the

Figur’s breakthrough DSF technology maintains high precision with a flexible, incremental forming approach through a proprietary build box design that reduces force distribution across the sheet during the build. This unique solution eliminates high startup costs and long-lead time associated with custom tools, molds, and dies to unlock the benefits of digitization for sheet metal manufacturers, improving their business agility and making sheet metal forming accessible to new applications across a range of volumes.

“After years of development, we’re excited to show our Digital Sheet Forming technology to sheet metal fabricators,” said

The Figur G15 features a software-driven ceramic toolhead on an XY gantry that progressively forms large metal sheets layer by layer with up to 2,000 lbs of force. With a forming area of 1450 x 1000 mm (57 x 39 in) in X and Y, the Figur G15 can process positive and negative forms up to 400 mm (16 in) in the vertical Z direction. A wide variety of metals and sheet thicknesses can also be processed – including steel up to 2.0 mm thick and aluminum up to 2.5 mm.

A video showing the production of parts on the Figur G15 can be viewed at figur.desktopmetal.com, where manufacturers can also reserve a system.

Additive Manufacturing 2.0 Live at IMTS 2022

IMTS, which will take place

Among the technology to be on display at the show:

● The Figur G15, will demonstrate its all-new Digital Sheet Forming (DSF) technology for steel, aluminum and more. Live demonstrations to be held two times a day at

● The Shop System™, now the world’s best-selling metal binder jetting system with new configurations for power users, including the Shop System+ and the Shop System Pro. Desktop Metal Booth 433103, and SolidCAM Booth 134502 in the

● The Production System™ P-1, an industrial manufacturing platform powered by Desktop Metal’s Single Pass Jetting™ technology. Booth 433103.

● The Studio System™, an office-friendly, two-step Bound Metal Deposition (BMD) printer, now featuring an industry-leading eight metal materials. SolidCAM Booth 134502.

● The S-Max® Flex, a robotic AM 2.0 system, makes sand 3D printing affordable to foundries worldwide. Designed for turnkey ease of use, S-Max Flex uses SPJ technology to print at high speeds delivering low part costs. Booth 432212.

● The ETEC Xtreme 8K, the world’s largest production-grade DLP polymer printer featuring two top-down video projectors, as well as the ETEC Envision One. ETEC systems 3D print a wide range of materials and exclusively offer DuraChain™ photopolymers, such as Elastic ToughRubber™ and FreeFoam™.

About

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in

View source version on businesswire.com: https://www.businesswire.com/news/home/20220907005468/en/

Media Relations:

(724) 516-2336

Sarahwebster@desktopmetal.com

Investor Relations:

(781) 730-2110

jaygentzkow@desktopmetal.com

Source:

FAQ

What is the Figur G15 launched by Desktop Metal?

When will the Figur G15 be showcased?

What materials can the Figur G15 process?

How does the Figur G15 technology benefit manufacturers?