Desktop Health Receives FDA Clearance for SmileGuard™ Resin for Durable and Comfortable Orthodontic and Dental Appliances

Desktop Health, a subsidiary of Desktop Metal (NYSE: DM), has received FDA 510(k) clearance for its innovative SmileGuard resin. This light-curable, biocompatible material allows dentists to 3D print customized bite splints and dental appliances in as little as one hour, providing same-day delivery. SmileGuard offers a unique combination of strength and comfort, overcoming common shortcomings in existing 3D printed dental materials. This breakthrough positions Desktop Health favorably in the rapidly growing market for digital dental solutions.

- SmileGuard resin achieves FDA 510(k) clearance, enhancing market position.

- Allows for same-day production of bite splints, improving patient experience.

- Combines strength and comfort, addressing limitations of current 3D printed materials.

- Part of a growing portfolio of advanced dental solutions.

- None.

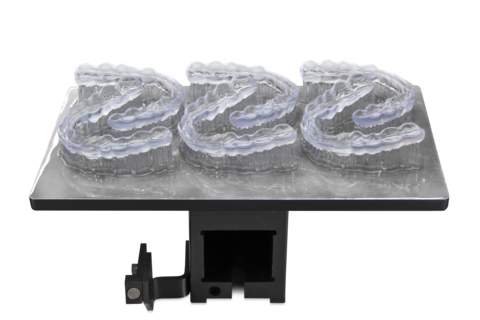

- Dentists and labs can use proprietary SmileGuard resin to 3D print bite splints, night guards, and mouth guards in the office in as little as one hour, allowing same-day delivery

- Compared to other 3D printed materials, SmileGuard delivers a superior blend of strength and comfort in a high-clarity product that is easy to keep clean

- 3D printed on Desktop Health’s high-accuracy Einstein™ 3D printing technology, Smileguard is easy to print, process, polish, and place

SmileGuard resin, which is now available for ordering and shipping, solves a challenge among 3D printed bite sprint solutions in the marketplace today. Among the available options, the strongest materials are often uncomfortable to patients, while softer materials are often not as durable.

In development for more than two years, SmileGuard resin, however, offers a superior blend of both strength and comfort, custom fit to a patient’s specific dental profile and needs. At the same time, it offers high impact resistance to teeth grinding, clenching, temporomandibular disorders (TMD), and abrasions.

“Every year, dentists and orthodontists prescribe millions1 of bite splints or night guards to prevent patients from clenching and grinding their teeth, which can cause pain, headaches, sleep disruption and also damage teeth,” said

The Digital Difference

Traditional analog methods to manufacture night guards require dental impressions that are sent to a lab to produce. At the lab, a splint is thermoformed on a model, which must be created, or it’s milled out of a puck and checked on a model for fit. Then, it must be polished and shipped to the dentist, with the complete turnaround time often averaging 2-3 weeks and requiring multiple patient visits.

With Desktop Health’s digital 3D printing workflow, SmileGuard resin can be used to manufacture night guards in as little as an hour and delivered to the patient the same-day. The patient is scanned in minutes during an office visit, where easy-to-use software enables the device to be designed and printed. Polishing takes just minutes to achieve a high shine.

3D printed bite splints and night guards are a fast growing segment in digital dentistry and one of the top 3 most common 3D printed dental applications. More than

Desktop Health’s Growing Leadership in 3D Printed Dental Solutions

SmileGuard resin joins a growing portfolio of

- The EinsteinTM 3D printer, designed specifically for dental professionals, delivers key features essential to superior 3D printing: accuracy, speed, and versatility. The Einstein’s NanoFit 385 technology delivers parts with stunning clarity, a perfect fit, and an impressive finish. Equipped with Hyperprint™ technology, which harnesses the power of heat and a closed-loop process, the Einstein prints up to 50 percent faster speed than its predecessor.

- FlexceraTM FDA-cleared materials for removable and restorative indications. Flexcera Base leverages proprietary long-chain chemistry to deliver one of the strongest dental resins on the market for the fabrication of 3D printed denture bases. Flexcera Smile Ultra+ provides the perfect blend of strength and flexibility coupled with a natural-looking, lifelike luster for a wide range of permanent and temporary dental restorations including, crowns, inlays, onlays, bridges, veneers, full and partial dentures.

About

About

Forward-Looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks and uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to the risks and uncertainties set forth in

__________________________

1JADA, Dental Splint Prescription Patterns: A Survey, 1995

2

View source version on businesswire.com: https://www.businesswire.com/news/home/20221006005202/en/

Media Relations

(724)516-2336

Sarahwebster@desktopmetal.com

Investor Relations

(781) 730-2110

jaygentzkow@desktopmetal.com

Source:

FAQ

What is SmileGuard resin and why is it significant for Desktop Metal (DM)?

How quickly can dentists use SmileGuard resin to produce dental appliances?

What are the key advantages of SmileGuard resin over traditional dental materials?

How does SmileGuard impact the dental industry's production process?