Velo3D Announces Sapphire XC 1MZ to Enable Large-format Metal 3D Printing up to One Meter in Height

Velo3D, a leader in metal additive manufacturing, announced the launch of the Sapphire XC 1MZ, its latest printer capable of producing parts up to one meter high. This new system features a build volume twice that of its predecessor and incorporates innovative features such as eight 1-kilowatt lasers and increased throughput by up to 400%. The initial units are set to be delivered to aerospace companies in late Q3 2022. This advancement aims to meet growing demands in industries like aerospace, energy, and defense.

- Launch of the Sapphire XC 1MZ, with a build volume twice that of the previous model.

- Increased throughput up to 400% compared to earlier models.

- Designed based on customer feedback from key sectors like aerospace and defense.

- None.

Insights

Analyzing...

New 1-meter Sapphire XC to

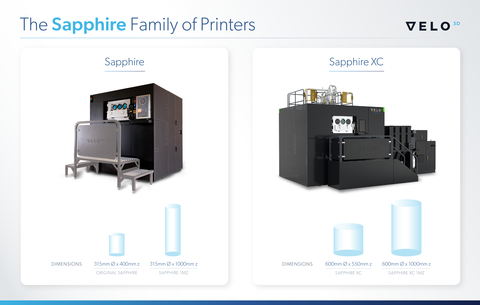

The Sapphire family of printers includes four unique system variations. Every Sapphire printer is fully compatible, delivering repeatable, consistent outcomes across any machine. As production limits are reached, customers can scale by simply adding another printer to their fleet. (Graphic: Business Wire)

Sapphire XC 1MZ continues Velo3D’s legacy of delivering leading-edge performance for metal additive manufacturing technology and has the largest laser powder bed fusion print volume from a leading manufacturer. The Sapphire XC 1 MZ system combines Velo3D’s innovative geometric capabilities with the repeatable, standardized processes and validated material properties necessary to achieve distributed manufacturing in a larger format. The Sapphire XC 1MZ was designed based on feedback from customers in the aerospace, energy, and defense industries, with the first systems expected to be delivered to several aerospace companies in late Q3 2022.

“Without advanced metal additive manufacturing it would be difficult to impossible to build many of the technologies that are shaping the future of our world,” said

Features of the Sapphire XC 1MZ include:

-

The largest build volume of any laser powder bed fusion printer in its class—600 mm x 1,000 mm—nine times larger than the original Sapphire and

30% larger than printers from other leading manufacturers - Eight 1-kilowatt lasers

- An integrated, end-to-end manufacturing solution including Flow print preparation software and Assure quality assurance software

- The Intelligent Fusion manufacturing process that has been proven in production on Sapphire and Sapphire XC for consistent, repeatable results across different printers

- Faster non-contact recoater to decrease the time required between build layers

-

Increased throughput of up to

400% over the original Sapphire and Sapphire 1MZ printers

The Sapphire XC 1MZ will be available in all the materials currently offered by

The Sapphire family of printers is comprised of four unique system variations that are fully compatible with one another, running the same processes across all printers in a way that delivers consistent results on any machine. This means that as customers validate one printer for production use, it is simple to add additional printers to increase productivity. The original Sapphire printer is capable of printing parts that are 315 mm in diameter and 400 mm in height. The Sapphire 1MZ prints at 315 mm in diameter and 1 meter in height. The Sapphire XC, which began shipping in Q4 2022, has a build volume of 600 mm in diameter by 550 in height.

The Sapphire XC 1MZ combines the large diameter of the Sapphire XC with the 1-meter build height of the Sapphire 1MZ to achieve the largest print volume of any laser powder bed fusion printer from a leading manufacturer. To learn more about the Sapphire XC 1MZ, visit the

About

Forward-Looking Statements

This press release includes “forward-looking statements” within the meaning of the “safe harbor” provisions of the Private Securities Litigation Reform Act of 1996. The Company’s actual results may differ from its expectations, estimates and projections and consequently, you should not rely on these forward-looking statements as predictions of future events. Words such as “expect”, “estimate”, “project”, “budget”, “forecast”, “anticipate”, “intend”, “plan”, “may”, “will”, “could”, “should”, “believes”, “predicts”, “potential”, “continue”, and similar expressions are intended to identify such forward-looking statements. These forward-looking statements include, without limitation, the Company’s expectations, hopes, beliefs, intentions or strategies for the future. These forward-looking statements involve significant risks and uncertainties that could cause the actual results to differ materially from the expected results. You should carefully consider the risks and uncertainties described in the documents filed by the Company from time to time with the

VELO,

Amperprint® 0233 Haynes® 282 Powder is produced by Höganäs under License from Haynes International, Inc.

View source version on businesswire.com: https://www.businesswire.com/news/home/20220616005179/en/

Media Contact:

press@velo3d.com

Investor Relations:

Bob Okunski, VP Investor Relations

investors@velo3d.com

Source: