Universal Robots Expands ‘Beyond the Welding Cart’ at FABTECH 2024

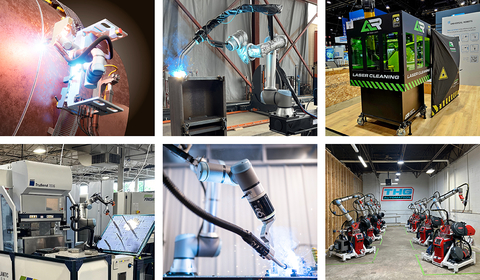

Universal Robots is set to expand its collaborative robotics (cobot) offerings at FABTECH 2024 in Orlando, showcasing advanced welding solutions for multi-axis, coordinated welding. New capabilities include extended reach, portability, and applications in laser restoration, finishing, and press brake tending.

UR’s new MotionPlus package enables dual-axis coordinated motion, allowing more complex welding tasks. Vectis Automation and THG Automation will demonstrate these new capabilities, including AI Path Optimization and multi-motion features. Hirebotics will leverage UR’s new PolyScope X platform for enhanced cobot welding functionalities.

New mobile cobot welders from Inrotech and Hyundai Welding will be introduced, targeting industries like shipbuilding and construction. Additional partner solutions include Mid Atlantic Machinery’s AutoTend for press brake integration and Cohesive Robotics’ Smart Finishing Workcell for automated surface finishing.

Universal Robots si prepara ad ampliare la sua offerta di robotica collaborativa (cobot) al FABTECH 2024 di Orlando, presentando soluzioni avanzate per la saldatura con sistemi di saldatura coordinati multi-assi. Le nuove funzionalità includono un raggio d'azione esteso, portabilità e applicazioni nella restaurazione laser, nella finitura e nella gestione delle presse piegatrici.

Il nuovo MotionPlus package di UR consente un movimento coordinato su due assi, permettendo di eseguire compiti di saldatura più complessi. Vectis Automation e THG Automation dimostreranno queste nuove capacità, inclusi l'ottimizzazione dei percorsi tramite intelligenza artificiale e funzionalità di movimento multiplo. Hirebotics sfrutterà la nuova piattaforma PolyScope X di UR per migliorare le funzionalità di saldatura dei cobot.

Nuove saldatrici cobot mobili di Inrotech e Hyundai Welding saranno introdotte, mirate a settori come la costruzione navale e l'edilizia. Ulteriori soluzioni dei partner includono l'AutoTend di Mid Atlantic Machinery per l'integrazione delle presse piegatrici e il Smart Finishing Workcell di Cohesive Robotics per la finitura automatizzata delle superfici.

Universal Robots está listo para expandir su oferta de robótica colaborativa (cobot) en FABTECH 2024 en Orlando, exhibiendo soluciones avanzadas de soldadura para soldadura coordinada de múltiples ejes. Las nuevas capacidades incluyen mayor alcance, portabilidad y aplicaciones en restauración láser, acabado y asistencia con prensas de freno.

El nuevo MotionPlus package de UR habilita el movimiento coordinado de doble eje, permitiendo tareas de soldadura más complejas. Vectis Automation y THG Automation demostrarán estas nuevas capacidades, incluyendo la Optimización de Ruta con IA y características de movimiento múltiple. Hirebotics aprovechará la nueva plataforma PolyScope X de UR para mejorar las funcionalidades de soldadura de cobots.

Nuevos soldadores cobot móviles de Inrotech y Hyundai Welding serán presentados, dirigidos a industrias como la construcción naval y la edificación. Otras soluciones de socios incluyen el AutoTend de Mid Atlantic Machinery para la integración de prensas de freno y el Smart Finishing Workcell de Cohesive Robotics para acabado automatizado.

유니버설 로봇은 FABTECH 2024에서 협업 로봇(cobot) 제품을 확장하며, 다축 조정 용접을 위한 첨단 용접 솔루션을 선보일 예정입니다. 새로운 기능으로는 더 넓은 작업 범위, 휴대성, 레이저 복원, 마감 및 프레스 브레이크 관리에 대한 응용이 포함됩니다.

UR의 새로운 모션 플러스 패키지는 이중 축 조정 움직임을 가능하게 하여 더 복잡한 용접 작업을 수행할 수 있도록 합니다. 벡티스 오토메이션과 THG 오토메이션은 AI 경로 최적화 및 다중 모션 기능과 같은 이러한 새로운 기능을 시연할 것입니다. 하이어로봇은 UR의 새로운 폴리스코프 X 플랫폼을 활용하여 cobot 용접 기능을 향상시킬 것입니다.

이노텍과 현대 용접의 새로운 모바일 cobot 용접기가 소개되어 조선업 및 건설 산업을 겨냥합니다. 추가 파트너 솔루션으로는 미드 앤틀랜틱 기계의 프레스 브레이크 통합을 위한 AutoTend와 코헤시브 로보틱스의 자동 표면 마감을 위한 스마트 마감 작업세트가 포함됩니다.

Universal Robots s'apprête à élargir son offre en robotique collaborative (cobot) lors de FABTECH 2024 à Orlando, présentant des solutions avancées de soudage pour le soudage coordonné multi-axes. Les nouvelles fonctionnalités incluent une portée étendue, portabilité et applications en restauration laser, finition et gestion de presses plieuses.

Le nouveau MotionPlus package de UR permet un mouvement coordonné à double axe, ce qui permet d'effectuer des tâches de soudage plus complexes. Vectis Automation et THG Automation démontreront ces nouvelles capacités, y compris l'optimisation de chemin par IA et des fonctionnalités de mouvement multiple. Hirebotics exploitera la nouvelle PolyScope X platform de UR pour améliorer les fonctionnalités de soudage des cobots.

De nouveaux soudeurs cobots mobiles de Inrotech et Hyundai Welding seront introduits, visant des industries telles que la construction navale et la construction. D'autres solutions de partenaires incluent l'AutoTend de Mid Atlantic Machinery pour l'intégration de presses plieuses et le Smart Finishing Workcell de Cohesive Robotics pour le finissage de surface automatisé.

Universal Robots wird sein Angebot an kollaborativer Robotik (Cobot) auf der FABTECH 2024 in Orlando erweitern und fortschrittliche Schweißlösungen für die koordiniertes Schweißen mit mehreren Achsen präsentieren. Zu den neuen Funktionen gehören ein erweiterter Aktionsradius, Portabilität und Anwendungen in der Laserrestaurierung, dem Finishen und der Bedienung von Abkantpressen.

Das neue MotionPlus-Paket von UR ermöglicht eine koordinierte Bewegung über zwei Achsen und erlaubt somit komplexere Schweißaufgaben. Vectis Automation und THG Automation werden diese neuen Fähigkeiten demonstrieren, darunter AI-Pfadoptimierung und Mehrfachbewegungsfunktionen. Hirebotics wird die neue PolyScope X-Plattform von UR nutzen, um die Schweißfunktionen der Cobots zu verbessern.

Neue mobile Cobot-Schweißer von Inrotech und Hyundai Welding werden vorgestellt und richten sich an Branchen wie den Schiffbau und den Bau. Weitere Partnerlösungen umfassen Mid Atlantic Machinerys AutoTend für die Integration von Abkantpressen und Cohesive Robotics Smart Finishing Workcell für automatisierte Oberflächenverarbeitung.

- Launch of new advanced welding solutions and capabilities at FABTECH 2024.

- Introduction of MotionPlus package for dual-axis coordinated motion, enhancing welding efficiency.

- New mobile cobot welders from Inrotech and Hyundai Welding, expanding market reach.

- Enhanced welding functionalities with PolyScope X platform by Hirebotics.

- None.

The leader of collaborative robotics continues to blaze the trail in the cobot welding landscape, featuring new advanced welding solutions for multi-axis, coordinated welding. New cobot capabilities will also be showcased in extended reach and portability applications, and in tasks such as laser restoration, finishing, and press brake tending.

FABTECH 2024 in

“UR cobots started out predominantly in air-cooled MIG welding solutions placed on carts,” says Will Healy III, global industry leader of welding at Universal Robots. “Now we see cobots take on heavier duty and more advanced tasks such as TIG, laser, and spot welding, along with plasma- and oxyfuel cutting.”

At Universal Robots’ FABTECH booth #4755, attendees will also witness UR cobots ‘going beyond the cart,’ expanding the work envelope. The show is the launchpad for dual-axis cobot welding with coordinated motion through the cobot’s own controller. “Having the cobot sync up with a rotary positioner or a linear rail, timing it within milliseconds, means our customers can now weld parts they normally couldn’t weld efficiently because they’d either have to stop and manually move the part, or weld it at two different times,” explains Healy.

A FABTECH first

The new capabilities are possible through UR’s new MotionPlus package that enables UR’s welding partners to add dual-axis coordinated motion capabilities to their own solutions. “To our knowledge, this is the first time multi-axis cobot welding with coordinated motion is showcased in North America,” says Healy.

Vectis Automation is one of the first UR partners to leverage MotionPlus, launching the RevoTM Dual Axis system at FABTECH. The new multi-axis positioning method can tackle more complex multi-faceted parts and excel in situations where the fabricator needs to get parts in position relative to gravity. Vectis will also showcase QuickTeach and AI Path Optimization; QuickTeach allows the cobot champion to teach points and optimize paths right at the torch. AI Path Optimization applies user-defined work angles, push/pull angles, and smoothed corner transitions to the weld path - ensuring the weld is always created according to the procedure specifications.

THG Automation will demonstrate multi-axis welding for the first time as well, their THG Multi-motion features a dual-axis skyhook with a part welded by a UR cobot mounted on a rail, all working in unison. THG is also launching the THG-Multi-Op; two all-in-one systems, one for MIG/TIG and one for cutting and welding, each system has a tool changer that allows the operator to easily switch between applications. Other new THG products at the show include a laser welding system and a new mobile base that gives the user flexibility to bring the system up to unusual sized parts.

PolyScope X redefines automation software

Having pioneered ease-of-use in cobot welding with the innovative Beacon-teaching app, Hirebotics is one of the first UR partners to leverage UR’s new PolyScope X platform, implementing Beacon on the UR cobot’s teach pendant in addition to iOS, Android, and any web-based device. Welders can now get instant in-app support through the UR teach pendant, watch instructional videos, and teach the cobot even complex welds in minutes. New advanced Hirebotics cobot welding features include Enhanced Stitch Welding; delivering the ability to stitch weld through complex paths and Fine Tune; allowing precise adjustments in torch angles and weld points, making it accessible for welders to optimize their work.

Cobot welding on the move

“Leaping off of the cart entirely, the lightweight and easily redeployable UR cobot is expanding onto new production floors through cobot portability,” shares Healy. “With portable cobots, welders in industries left out of automation like ship building and construction now have access to a powerful tool to improve productivity and eliminate boring repetitive work. Welders no longer need to be contortionists bending into uncomfortable positions to reach the joint for long hours each day.”

New innovative deployment of cobot welders includes the Inrotech-Crawler making its FABTECH debut, featuring UR’s smallest UR3 cobot placed on a carriage running on a flexible rail system fixed to the substrate. The Inrotech-Crawler specializes in butt-weld connections and multi-pass welding, regardless of the shape or orientation. The robot continuously adjusts the welding parameters according to its changing position (e.g. around a pipe).

Another mobile cobot welder making a premiere at FABTECH is Hyundai Welding’s portable cobot welding system. Hyundai Welding has worked with the world’s largest and most advanced shipyards to develop an agile solution addressing the tight working environments in welding sections, especially inside-block welding of the ship’s hull.

Cobots in press brake tending, finishing, and laser restoration

Welding is not the only task expertly handled by cobots at FABTECH. Alongside demos from Hirebotics, and Vectis Automation, UR’s own booth features the following partner solutions:

The robotic machine tending system AutoTend from Mid Atlantic Machinery, a press brake integration solution featuring a UR10e cobot. AutoTend will bend a candy dish part from type 304 stainless steel. The demo will showcase Mid Atlantic’s patented rotary end-of-arm tooling while demonstrating the ability of the cobot to bend complex parts while interacting directly with the press brake touch screen control.

The Smart Finishing Workcell from Cohesive Robotics, a game-changer for automated surface finishing tasks. At the show, Cohesive Robotics will demonstrate autonomous scanning and on-the-fly programming of a UR cobot to simulate various finishing processes in the booth. Designed for high-mix manufacturing operations, the work cell leverages machine vision and AI to perform common material removal and surface finishing processes on nearly any part, of any quantity, and with no programming required.

Advanced Laser Restoration will be showcasing the next generation of laser cleaning technology, highlighting the seamless integration of advanced laser cleaning systems with robotic automation. By pairing laser cleaning technology with the agility of Universal Robots' systems, Advanced Laser Restoration automates surface preparation tasks such as rust and coating removal with pinpoint accuracy, reducing downtime and enhancing productivity.

For attendees looking for a guided, insightful introduction to the many new fabricating applications and solutions powered by UR cobots, Universal Robots is hosting Cobot Walks at FABTECH for the first time. The focused tour introduces participants to live demonstrations, expert insights, future trends, networking opportunities, and interactive Q&As.

Download images: Here

About Universal Robots

Universal Robots is a global leader in collaborative robotics (cobots), used across a wide range of industries. Our mission is simple: Automation for anyone. Anywhere. With over 90,000 cobots sold worldwide, our user-friendly platform is supported by intuitive PolyScope software, award-winning training, comprehensive services, and the world’s largest cobot ecosystem, delivering innovation and choice to our customers. Universal Robots is part of Teradyne Robotics, a division of Teradyne (NASDAQ:TER), a leading supplier of automatic test equipment and advanced robotics technology.

View source version on businesswire.com: https://www.businesswire.com/news/home/20241011728383/en/

Media contact:

Mette McCall, McCall Media

mette@mccallmedia.net

251-278-9847

Source: Universal Robots

FAQ

What new welding capabilities will Universal Robots showcase at FABTECH 2024?

What is the new MotionPlus package introduced by Universal Robots?

Which companies will demonstrate new cobot capabilities at FABTECH 2024?

What new mobile cobot welders will be introduced at FABTECH 2024?