Desktop Metal Installations of Additive Manufacturing Systems for Metal Parts Now Surpass 1,100 Units Worldwide

- Fast growing adoption of binder jet technology showcases the material flexibility and mass production capability of high-speed, area-wide 3D printing technology

-

Desktop Metal will host an open house onJan. 25 to showcase the fastest binder jet metal 3D printing technology on the Production System™ P-50 -

Thirty metal alloys are now available on

Desktop Metal turnkey and production printing systems, from stainless steels and tool steels, to precious and reactive metals, such as aluminum and titanium

Desktop Metal’s portfolio now offers the widest selection of mass production 3D printing systems for the final production of metal components.

More than

“As the highest throughput process in 3D printing, binder jetting is the additive manufacturing technology that will truly take the industry into mass production at high volumes,” said

Binder Jet is a Differentiated AM Solution

Binder jet 3D printing is one of seven additive manufacturing processes recognized by ASTM. The process transforms virtually any powdered materials — metal, sand or ceramic — into functional precision parts and tools at high speeds. An industrial printhead selectively deposits a binder into a bed of powder particles creating a solid part one thin layer at a time, just like printing on sheets of paper. The technology is viewed as a desirable and sustainable production method, largely because of its high speed, low waste and cost, as well as material flexibility.

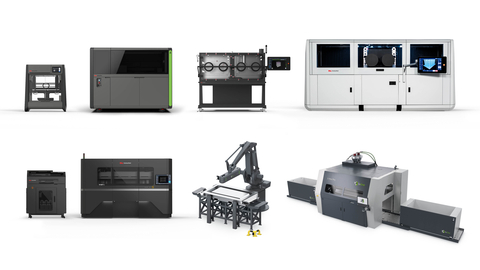

The company’s portfolio offers the widest selection of mass production solutions for metal 3D printing:

- The Production System™ P-50 — the world’s fastest metal binder jet system, offering the lowest cost per part, featuring Single Pass Jetting (SPJ) technology.

- The X160Pro™ — the world’s largest binder jet system for the production of both metal and ceramics, featuring Triple Advanced Compaction Technology (ACT).

- The S-Max® Pro — the world’s best selling brand of sand binder jet 3D printing systems for sandcasting molds and cores for aluminum and ferrous metal castings.

- The S-Max® Flex — an affordable binder jet 3D printing system for digital sandcastings.

- The Production System™ P-1 — the world’s best selling platform for qualifying binder jet 3D printing for serial production.

- The InnoventX™ — the world’s best-selling metal binder jet system in academia.

- The Shop System™ — the world’s best-selling metal binder jet system.

- The Studio System™ — the best-selling Bound Metal Deposition (BMD) system with only two steps and the widest material selection offered in its category.

An open house to showcase the performance capabilities of the Production System P-50 will be held on

Desktop Metal’s 2022 material guide, which outlines the company’s comprehensive range of printable materials and systems on which they are qualified, can be downloaded at teamdm.com/materialguide.

About

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in

View source version on businesswire.com: https://www.businesswire.com/news/home/20221206005331/en/

Media Relations:

(724)516-2336

Sarahwebster@desktopmetal.com

Investor Relations:

(781) 730-2110

jaygentzkow@desktopmetal.com

Source: