Desktop Metal and Evonik Expand Partnership, Announce Qualification of Photopolymer on Large Format Additive Manufacturing 2.0 Systems for High-Performance, High-Temperature Products

- None.

- None.

Insights

The announcement of Evonik's INFINAM® ST 6100 L qualification for use on Desktop Metal's ETEC Xtreme 8K and ETEC Pro XL printers is a significant development in the additive manufacturing industry. This collaboration between a materials provider and a 3D printer manufacturer signals a strategic move to enhance the capabilities of 3D printing technology for industrial applications. The emphasis on high-strength photopolymer resins with resistance to temperature, water, chemicals and UV is likely to meet the demanding requirements of sectors like aerospace, automotive and electronics.

From a market perspective, the ability to produce molds, models, tooling and end-use parts with such advanced materials could potentially lead to cost savings, increased productivity and the opening of new markets for both companies. The high-throughput capabilities of the ETEC Xtreme 8K, combined with the affordability of the ETEC Pro XL, position Desktop Metal to capture a larger share of the market. This could result in increased investor confidence and a positive impact on Desktop Metal's stock performance in the medium to long term.

The technical specifications of INFINAM® ST 6100 L, such as its ultimate tensile strength, flexural stress and heat deflection temperature, make it a benchmark material in the 3D printing industry. The ability to machine and polish parts post-printing enhances the material's versatility, potentially leading to broader adoption across various industries. The collaboration's focus on Digital Light Processing (DLP) technology, known for its speed and precision, is indicative of the industry's trend towards high-efficiency production techniques.

The material's properties suggest that it could withstand the rigorous demands of aerospace and automotive applications, which often require parts that can endure extreme conditions. The validation of this material on Desktop Metal's printers could spur innovation in material science, leading to further advancements in the strength and durability of photopolymer resins.

The strategic partnership between Evonik and Desktop Metal is likely to enhance the financial outlook for both companies. The qualification of INFINAM® ST 6100 L for high-volume production printers addresses a growing demand for strong, durable and versatile materials in additive manufacturing. This could lead to an increase in sales for Evonik's high-performance resins and Desktop Metal's printing systems, potentially boosting revenue streams for both entities.

Investors should consider the implications of this development on the companies' financial health, including potential increases in market share and competitive positioning. The cost-effectiveness of the ETEC Pro XL, in particular, may attract a wider customer base and drive volume growth, while the high-throughput capabilities of the ETEC Xtreme 8K could lead to significant economies of scale for large-scale production.

- Evonik INFINAM® ST 6100 L is now qualified for 3D printing on the ETEC Xtreme 8K and ETEC Pro XL from Desktop Metal

- INFINAM® ST 6100 L is one of the highest strength photopolymer resins on the market with high temperature, water, chemical, and UV resistance

- The ETEC Xtreme 8K is the world’s largest production-grade DLP printer for high-volume production of tooling and end-use parts

-

The ETEC Pro XL is a high-speed, precision DLP printing system with an extra-large build area for under

$40,000 - INFINAM® ST 6100 L printed on ETEC hardware is ideal for the production of molds, models, and tooling, as well as end-use parts in the aerospace, automotive, or electronics industries

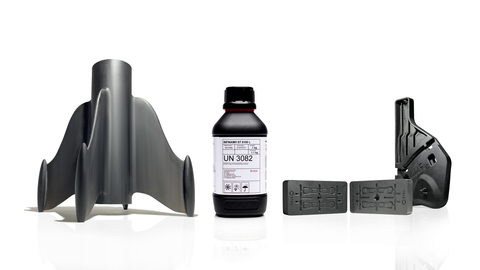

Evonik INFINAM® ST 6100 L printed on ETEC hardware from Desktop Metal is ideal for the production of molds, models, and tooling, as well as end-use parts in the aerospace, automotive, or electronics industries. (Photo: Business Wire)

Evonik INFINAM® ST 6100 L is a benchmark material in high-strength photopolymers for 3D printing. With an ultimate tensile strength (UTS) of 90 MPa, flexural stress of 135 MPa, and heat deflection temperature (HDT) of 120 °C, the material also delivers exceptional accuracy, surface finish, and resistance to many chemicals and UV degradation.

Desktop Metal’s ETEC brand for polymer 3D printing is a leader in Digital Light Processing (DLP) hardware and a carefully curated portfolio of the world’s best AM materials.

“Desktop Metal is delighted to add Evonik and its INFINAM® material to our highly selective portfolio of polymers, as we continue to offer customers the flagship material solutions in each performance class, ranging from stiff rigid plastics to high strength-to-weight ratio elastomers and foams,” said Walter Voit, Senior Vice President for Polymer Materials at Desktop Metal. “Our hardware systems offer the size, speed, and quality required for high-throughput Additive Manufacturing 2.0 production of premium photoresins like ST 6100L.”

“Collaboration with customers and partners is an important driver of innovation for us,” said Vitor Lavini, head of Evonik’s photopolymer market segment in the company’s Additive Manufacturing Innovation Growth Field. “The validation of ST 6100 L on Desktop Metal’s printers – especially the ETEC Xtreme 8K – fits with Evonik’s vision that larger and faster DLP printers will increase productivity, substantially reduce costs per part, and enable series production in the long run.”

The properties offered by INFINAM® ST 6100 L make the material ideal for 3D printed production of molds, models, and tooling, as well as end-use parts in the aerospace, automotive, or electronics industries. Additionally, tools or parts 3D printed in INFINAM® ST 6100 can deliver very precise features and a smooth surface finish, especially when paired with the crisp 65 μm resolution offered on the ETEC Pro XL. Parts printed in this material can also be machined and polished, in addition to other post-processing techniques.

High-Throughput Production with Breakthrough Materials

A 3D printing process in use since 1999, DLP harnesses the power of light from a video projector to cure photosensitive liquid resins into parts layer by layer, one quick flash at a time. DLP is one of the fastest, most accurate forms of polymer 3D printing, delivering high accuracy and a smooth surface finish with consistent materials properties.

The ETEC Xtreme 8K is the world’s largest industrial-grade DLP printer for high-volume production. With a 66-liter build volume and two overhead projectors, the Xtreme 8K is ideal for high-throughput tooling and end-use part applications, as well as the production of larger parts. The ETEC Xtreme 8K offers a build volume of 450 × 371 x 399 mm (17.72 x 14.61 x 15.71 in). The system is produced at Desktop Metal’s Polymer Center of Excellence in

Priced for purchase at under

Parts 3D printed on the ETEC Xtreme 8K in Evonik INFINAM® ST 6100 L material will be on display during the 2024 Additive Manufacturing Users Group (AMUG) Conference in

For more information, visit TeamDM.com/ETEC_Evonik.

About Desktop Metal

Desktop Metal (NYSE:DM) is driving Additive Manufacturing 2.0, a new era of on-demand, digital mass production of industrial, medical, and consumer products. Our innovative 3D printers, materials, and software deliver the speed, cost, and part quality required for this transformation. We’re the original inventors and world leaders of the 3D printing methods we believe will empower this shift, binder jetting and digital light processing. Today, our systems print metal, polymer, sand and other ceramics, as well as foam and recycled wood. Manufacturers use our technology worldwide to save time and money, reduce waste, increase flexibility, and produce designs that solve the world’s toughest problems and enable once-impossible innovations. Learn more about Desktop Metal and our #TeamDM brands at www.desktopmetal.com.

About Evonik

Evonik is one of the world leaders in specialty chemicals. The company is active in more than 100 countries around the world and generated sales of

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in Desktop Metal, Inc.'s filings with the

View source version on businesswire.com: https://www.businesswire.com/news/home/20240305115052/en/

Investor Relations:

(857) 504-1084

DesktopMetalIR@icrinc.com

Media Relations

Sarah

sarahwebster@desktopmetal.com

(313) 715-6988

Source: Desktop Metal, Inc.