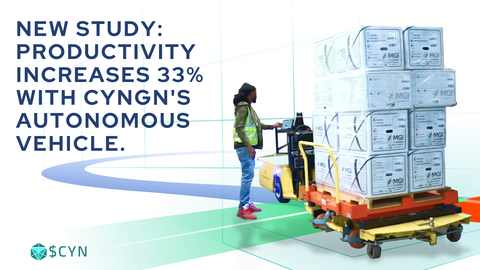

New Study: Cyngn’s Autonomous Industrial Vehicles Increased Productivity by 33%

According to Cyngn’s research, the deployment of an autonomous vehicle at GLF’s

-

a

64% reduction in human labor costs, when compared to using forklifts. -

a

33% increase in productivity when compared to using electric pallet jacks.

“The data speaks for itself,” says

In addition to the increased productivity, Cyngn’s autonomous Stockchaser delivered supplemental benefits. The vehicle provided GLF management with real-time data and reporting on operational analytics, created a safer working environment for GLF employees, and enabled further growth of GLF’s client base. Lastly, the Stockchaser served as tangible proof of GLF’s commitment to innovation, empowering them to continue surpassing their clients’ expectations.

“Working with

As a result of the global e-commerce boom, the warehousing industry is experiencing rapid growth and even industry stalwarts are struggling to scale their operations to meet burgeoning demand. Consequently, traditional labor resources are drying up and becoming more expensive.

Global Logistics & Fulfillment (“GLF”) is no stranger to these trends. For more than 25 years, the company has been a leading provider of distribution, fulfillment, and 3rd-party logistics services. With warehouses in

Facing rising labor costs, increasingly demanding customers, and an urgent need to scale their business, GLF sought an innovative solution to streamline their operations. Enter

Deploying Cyngn’s DriveMod Autonomous Vehicle technology at GLF involved a simple, yet robust set of steps:

-

Conduct a site assessment. First,

Cyngn interviewed GLF’s operations managers to obtain a thorough understanding of GLF’s process flows. Then, Cyngn’s field engineers surveyed GLF’s facility to document the operational design domain (“ODD”) including the lighting, lane widths, and types of obstacles the vehicle could encounter. From this,Cyngn was able to identify the transporting of pallets from an order fulfillment station to outbound shipping as the optimal use case for the deployment. -

Map the facility. In order for an AV to operate, it must know where it is within its environment. To accomplish this,

Cyngn scanned the entirety of GLF’s facility to create a detailed virtual map. -

Bring-up the vehicle. Once the map was created,

Cyngn worked with GLF management to define the vehicle’s missions, which included the routes the vehicle would take and the stops where pallets could be loaded and unloaded onto the vehicle. -

Train key personnel. Finally, before the vehicle was brought into full autonomous operation,

Cyngn trained GLF employees on safe use of the vehicle. Then, it was seamlessly integrated into their daily workflow.

To read the complete report, click here.

About

To learn more, please visit https://cyngn.com/.

Find

Forward-Looking Statements

This press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. Any statement that is not historical in nature is a forward-looking statement and may be identified by the use of words and phrases such as "expects," "anticipates," "believes," "will," "will likely result," "will continue," "plans to," "potential," "promising," and similar expressions. These statements are based on management's current expectations and beliefs and are subject to a number of risks, uncertainties and assumptions that could cause actual results to differ materially from those described in the forward-looking statements, including the risk factors described from time to time in the Company’s reports to the

View source version on businesswire.com: https://www.businesswire.com/news/home/20220728005334/en/

Vice President, The Equity Group

csohn@equityny.com

(415) 568-2255

Source: