U. S. Steel and CarbonFree Sign Definitive Agreement to Capture Carbon Dioxide Emissions at One of the Largest North American Integrated Steel Mills

- None.

- None.

Insights

Steel manufacturing is one of the most carbon-intensive industries, contributing significantly to global CO2 emissions. The partnership between U. S. Steel and CarbonFree indicates a strategic move towards sustainable practices within the sector. The adoption of SkyCycle technology to capture and mineralize carbon dioxide directly from blast furnace emissions is a proactive approach to meet regulatory demands and societal expectations for cleaner production processes. Given the industry's historical reliance on carbon-heavy operations, this initiative may set a precedent for other companies to follow, potentially influencing environmental policies and regulations. The long-term impact on U. S. Steel could be substantial, not only in meeting its emission reduction targets but also in strengthening its market position as a provider of 'greener' steel, which is increasingly demanded by environmentally conscious consumers and industries.

The announcement of the carbon capture project could have a positive effect on U. S. Steel's brand image and stock value, as investors and customers alike are showing a preference for companies with strong environmental credentials. The ability to offer carbon-neutral calcium carbonate as a byproduct of the steel manufacturing process opens up new market opportunities for U. S. Steel and could provide a competitive edge. The focus on reducing Scope 3 emissions, which include indirect emissions in a company's value chain, is particularly relevant as these emissions are often the largest share of a corporation's carbon footprint. This project may also act as a risk mitigation strategy against future carbon taxes or emissions trading schemes, which are likely to become more stringent as governments intensify efforts to combat climate change.

U. S. Steel's investment in CarbonFree's SkyCycle technology is a noteworthy advancement in industrial process innovation. The ability to capture and repurpose carbon emissions from blast furnaces not only addresses the environmental challenges but also adds economic value by creating a secondary product. This dual benefit is important for the feasibility and scalability of such technologies. The use of blast furnace slag in the production of calcium carbonate is an example of circular economy principles applied in heavy industry, which can lead to cost savings and resource efficiency. The potential expansion of this technology across U. S. Steel's operations could lead to significant advancements in emission reduction techniques within the steel industry. Moreover, the collaboration with CarbonFree could spur further innovation in carbon capture and utilization, which is essential for the transition to a low-carbon economy.

- The agreement sets in motion a project to capture emissions from U. S. Steel’s blast furnaces

-

CarbonFree’s SkyCycle™ technology will capture and mineralize up to 50,000 metric tons of carbon dioxide annually at U. S. Steel’s facility in

Gary, Indiana , to convert emissions into specialty-grade, carbon-neutral calcium carbonate -

The project will be the first commercial-scale carbon capture utilization plant at a steel plant in

North America

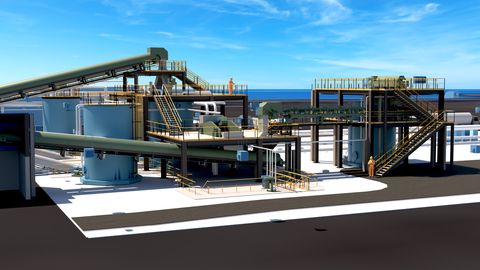

3D rendering of CarbonFree's SkyCycle plant that will be built at U. S. Steel's Gary Works operation. Photo Credit: Fluor Corporation

U. S. Steel’s involvement aligns with its goal of reducing greenhouse gas emissions intensity

Construction on the SkyCycle plant in the U. S. Steel Gary Works facility is expected to commence as early as summer 2024 with operations projected to begin in 2026. The definitive agreement has a term of 20 years following its in-service date.

CarbonFree’s patented SkyCycle solution captures carbon emissions from hard-to-abate industrial sources before they enter the atmosphere and converts them into a carbon-neutral version of calcium carbonate, which is essential to the creation of paper and plastics, as well as personal care, paint, and building products. CarbonFree-produced calcium carbonate made from captured carbon dioxide can help decarbonize global supply chains by enabling manufacturers to reduce Scope 3 emissions, or it can be stored in an environmentally conscious way without the need for pipelines or disposal wells.

“U. S. Steel is setting a precedent for how manufacturers can and must proactively manage their carbon emissions, and CarbonFree is honored to play a role in this legacy,” said Martin Keighley, CEO of CarbonFree. “At CarbonFree, we are pioneering profitable carbon capture utilization through disruptive specialty chemical manufacturing using waste carbon dioxide as a primary feedstock. As carbon capture continues to be recognized as an indispensable solution on the path to carbon neutrality for carbon-intensive industries, we look forward to helping U. S. Steel achieve its decarbonization goals while providing economic and environmental benefits to the city of

By leveraging cutting-edge carbon capture technologies, U. S. Steel and CarbonFree aim to revolutionize the steel manufacturing industry, reducing carbon emissions and environmental impact. The partnership will likely enable U. S. Steel to offer steel used in the automotive, appliance, and packaging industries with a significantly reduced carbon footprint.

In addition to capturing carbon dioxide, CarbonFree will use slag produced by the blast furnace operation as part of the calcium carbonate production process.

“Innovating to capture carbon at an integrated mill is the latest example of how steel is enabling a more sustainable future,” said Scott Buckiso, Senior Vice President & Chief Manufacturing Officer, U. S. Steel. “Moreover, U. S. Steel has a history of ‘firsts’ that we’re confidently building on. Using SkyCycle technology for the first project of its kind in

U. S. Steel employs more than 4,300 people at Gary Works. The plant creates an Economic Multiplier Effect, supporting thousands of additional steel plant, chemical, energy, transportation and supplier jobs throughout Lake and Porter Counties and the greater

For more information on SkyCycle, visit the CarbonFree website or follow on LinkedIn.

For more information on U. S. Steel, please visit www.ussteel.com.

About U. S. Steel

Founded in 1901, United States Steel Corporation is a leading steel producer. With an unwavering focus on safety, U. S. Steel’s customer-centric Best for All® strategy is advancing a more secure, sustainable future for U. S. Steel and its stakeholders. With a renewed emphasis on innovation, U. S. Steel serves the automotive, construction, appliance, energy, containers, and packaging industries with high value-added steel products such as U. S. Steel’s proprietary XG3® advanced high-strength steel. U. S. Steel also maintains competitively advantaged iron ore production and has an annual raw steelmaking capability of 22.4 million net tons. U. S. Steel is headquartered in

About CarbonFree

CarbonFree is a carbon capture company committed to the decarbonization of hard-to-abate industries and global supply chains. Its SkyCycle technology captures carbon dioxide produced from industrial plants before entering the atmosphere then converts the emissions into chemicals that are pivotal to the specialty chemicals market. CarbonFree’s first-generation technology, SkyMine, has been operational since 2016 and is one of the world’s first and largest industrial-scale carbon mineralization facilities, operating alongside a cement factory in

View source version on businesswire.com: https://www.businesswire.com/news/home/20240403431370/en/

CarbonFree Media Relations

Email: carbonfree@berlinrosen.com

Phone: 516-659-9369

U. S. Steel Media Relations

E – media@uss.com

T - (412) 433-1300

Source: CarbonFree