Western Exploration Reports Positive Doby George Metallurgical Results, Including Average Recoveries of 72%

- None.

- None.

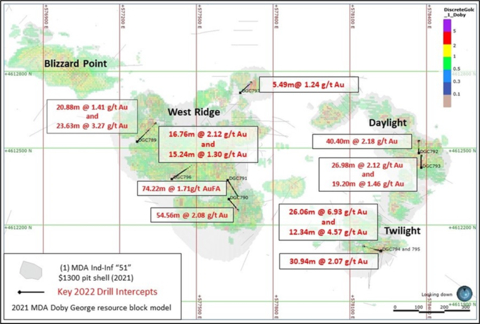

Figure 1 : Location of 2022 PQ Metallurgical test holes and key intercepts, relative to resource zones and the modeled

Highlights from the work include:

-

Column test work conducted by McClelland Laboratories, Inc. ("MLI") of

Reno, Nevada on PQ core from 2022 drilling returned (i) average leach recoveries of65% (range56.1% to77.8% ) for -50 mm (2 inch) feed size, and (ii) average recoveries of72% (range64% to81.8% ) for80% -12.7 mm (1/2 inch) feed size. - Cyanide consumption was low and expected to be below 0.4 kilogram NaCN/metric ton ("kgNaCN/mt") of ore for 12.7 mm crush size and hydrated lime consumption of between 0.7 to 2.0 kilogram/metric ton ("kg/mt") of ore during commercial leaching.

- "Load permeability" tests on residual leached 12.7 mm material indicated adequate permeability for commercial heap leach stack heights of up to 91 meters (300 feet) without any pretreatment agglomeration.

Western Exploration CEO, Darcy Marud, said, "Western Exploration is pleased that the Doby George metallurgical results report high leach recovery rates that are consistent with past metallurgical work. The completed test work is a key milestone identified in the 2021 technical report and a key component needed to advance the Doby George deposits towards a pre-feasibility study."

2023 Column Leach Metallurgy Results

A detailed heap leach testing program was conducted on drill composites representing gold bearing oxide and mixed materials collected from the Doby George deposit with PQ drilling in 2022 (Figure 1). Agitated cyanidation bottle roll tests were conducted on a total of 46 drill core composites to obtain preliminary information regarding heap leach amenability and ore variability. The results of the bottle roll tests were reported in the Company's news release dated July 10, 2023 and entitled "Western Exploration Reports Average of

Table 1 : Summary Metallurgical Results, Cyanide Leach Tests, Doby George Column Composites

Gram Au/metric ton ore |

Reagent Requirements,

|

|||||||||

Feed

|

Test

|

Leach Time,

|

Au Rec.,

|

Extracted |

Tail |

Calculated

|

Avg.

|

NaCN

|

Lime

|

|

4838-047, NW Ridge, DGC789, Oxide |

||||||||||

-50 mm |

CLT |

113 |

77.8 |

1.12 |

0.32 |

1.44 |

1.54 |

|

0.41 |

0.9 |

|

CLT |

114 |

81.8 |

1.35 |

0.30 |

1.65 |

1.54 |

|

0.78 |

0.9 |

|

BRT |

4 |

85.5 |

1.30 |

0.22 |

1.52 |

1.54 |

|

<0.10 |

0.9 |

4838-048, West Ridge Starter Pit - Upper, DGC790/DGC791, Oxide |

||||||||||

-50 mm |

CLT |

113 |

56.1 |

1.05 |

0.82 |

1.87 |

1.77 |

|

0.46 |

0.8 |

|

CLT |

114 |

64.0 |

1.26 |

0.71 |

1.97 |

1.77 |

|

0.82 |

0.8 |

|

CLT |

114 |

68.1 |

1.28 |

0.60 |

1.88 |

1.77 |

|

0.86 |

0.8 |

|

BRT |

4 |

71.9 |

1.23 |

0.48 |

1.71 |

1.77 |

|

0.26 |

0.8 |

4838-049, West Ridge Starter Pit - Lower, DGC790/791, Oxide |

||||||||||

-50 mm |

CLT |

113 |

60.2 |

1.12 |

0.74 |

1.86 |

1.73 |

|

0.50 |

0.7 |

|

CLT |

120 |

70.1 |

1.29 |

0.55 |

1.84 |

1.73 |

|

0.81 |

0.7 |

|

BRT |

4 |

77.1 |

1.31 |

0.39 |

1.70 |

1.73 |

|

0.20 |

0.7 |

4838-050, Daylight, DGC792, Oxide |

||||||||||

-50 mm |

CLT |

133 |

69.9 |

1.14 |

0.49 |

1.63 |

1.50 |

|

0.95 |

2.0 |

|

CLT |

134 |

78.8 |

1.30 |

0.35 |

1.65 |

1.50 |

|

1.11 |

2.0 |

|

BRT |

4 |

80.1 |

1.25 |

0.31 |

1.56 |

1.50 |

|

0.12 |

2.0 |

4838-051, Daylight, DGC793, Oxide |

||||||||||

-50 mm |

CLT |

120 |

57.4 |

0.89 |

0.66 |

1.55 |

1.32 |

|

0.75 |

1.9 |

|

CLT |

120 |

66.7 |

1.00 |

0.50 |

1.50 |

1.32 |

|

1.05 |

1.9 |

|

BRT |

4 |

65.5 |

0.91 |

0.48 |

1.39 |

1.32 |

|

0.14 |

1.9 |

4838-054, Twilight, DGC794/DGC795, Oxide/Mixed |

||||||||||

-50 mm |

CLT |

113 |

67.9 |

1.65 |

0.78 |

2.43 |

2.42 |

|

0.64 |

0.9 |

|

CLT |

120 |

72.9 |

1.83 |

0.68 |

2.51 |

2.42 |

|

0.96 |

0.9 |

|

BRT |

4 |

71.4 |

1.80 |

0.72 |

2.52 |

2.42 |

|

0.19 |

0.9 |

4838-055, West Ridge Deep, DGC796, Mixed |

||||||||||

|

CLT |

30 |

6.1 |

0.06 |

0.93 |

0.99 |

0.99 |

|

0.18 |

1.1 |

|

BRT |

4 |

3.2 |

0.03 |

0.91 |

0.94 |

0.99 |

|

0.26 |

1.1 |

*CLT is Column Leach Test |

||||||||||

| BRT is Bottle Roll Test (previously reported in the Company's news release dated July 10, 2023 and entitled "Western Exploration Reports Average of |

||||||||||

All five oxide composites were amenable to simulated heap leach cyanidation treatment at both feed sizes evaluated. This includes composites from the West Ridge and Daylight areas. Gold recoveries obtained at the -50 mm feed size ranged from

A single composite of material from the Twilight area was tested. That composite included a blend of oxide and mixed material. Gold recoveries obtained from the composite at the -50 mm and -12.7 mm feed sizes were

A single composite of deep mixed material from the West Ridge area was column tested at the -12.7 mm size. That material was not amenable to heap leaching at that feed size. The column test gold recovery was only

Gold recovery rates were moderate, and with the exception of composite 4838-047, were not particularly sensitive to feed size (Figure 2-Figure 4). In the case of composite 4838-047, crushing from -50 mm to -12.7 mm in size significantly increased the gold recovery rate. In all cases gold extraction was progressing at a slow rate (~

Oxide and oxide/mixed column test cyanide consumptions were moderate and ranged from 0.41 to 1.11 kgNaCN/mt of ore. Commercial consumptions should be significantly lower and would probably not exceed 0.4 kgNaCN/mt ore for heap leaching of the oxide material at an

Fixed wall hydraulic conductivity tests conducted on the -12.7 mm feed size column leached residues showed that the material types tested are expected to be adequately permeable for commercial heap stack heights to up to 91 meters (330 feet) without the need for agglomeration.

MLI recommends additional column leach test work on low grade drill composites to further study the relationship of grade and recovery, the evaluation of high-pressure grinding roll crushing on higher grade material and additional ore variability bottle roll test work for geometalurigical modeling of the deposit.

About Doby George

Doby George is one of the highest-grade, undeveloped open pit heap leach resources in

Homestake Mining Company initially discovered the deposit in the mid-1980s. Since that time, 836 drill holes have been completed, totaling 116,355 meters of drilling. This includes 83 drill holes totaling 23,760 meters that were drilled by Western Exploration LLC between 1998 and 2022. Metallurgical test work completed on oxidized material by Homestake Mining Company, Independence Mining Company, and Atlas Precious Metals Inc., has indicated favorable metallurgy for standard cyanide heap leach processing. Results from the previous metallurgical testing completed on 52 bottle rolls and 23 column leach samples indicate that heap leach gold recoveries approaching seventy percent can be expected via a crush of 1 to 1.5 inches.

In addition to an established mineral resource estimate (as determined in accordance with National Instrument 43-101 – Standards of Disclosure for Mineral Projects ("NI 43-101")) as outlined in the NI 43-101 technical report entitled "2021 Updated Resource Estimates and Technical Report for the Aura Gold-Silver Project,

The 6,000-hectare Aura Project has identified mineral resources in three different deposits (Doby George, Gravel Creek, and Wood Gulch), as supported by Technical Report (see Table 2 below).

Table 2: Updated mineral resource estimates for the Aura Project as contained in the Technical Report.

MINERAL RESOURCE ESTIMATE(1) |

||||||||||||||

|

Indicated |

Inferred |

||||||||||||

Tonnes |

Au

|

Au

|

Ag

|

Ag

|

AuEq

|

AuEq

|

Tonnes |

Au

|

Au

|

Ag

|

Ag

|

AuEq

|

AuEq

|

|

Doby George(2) |

12,922,000 |

0.98 |

407,000 |

- |

- |

0.98 |

407,000 |

4,999,000 |

0.73 |

118,000 |

- |

- |

0.73 |

118,000 |

Wood Gulch(3) |

- |

- |

- |

- |

- |

- |

- |

4,359,000 |

0.66 |

93,000 |

5.80 |

808,000 |

0.74 |

104,543 |

Gravel Creek(4) |

1,315,000 |

4.73 |

200,000 |

75.0 |

3,169,000 |

5.81 |

245,271 |

2,744,000 |

4.16 |

367,000 |

60.20 |

5,307,000 |

5.02 |

442,814 |

TOTAL |

14,237,000 |

1.33 |

607,000 |

75.0 |

3,169,000 |

1.43 |

652,271 |

12,102,000 |

1.48 |

578,000 |

15.74 |

6,115,000 |

1.71 |

665,357 |

Notes:

|

||||||||||||||

See "Cautionary Statements Regarding Estimates of Mineral Resources" below.

About Western Exploration

Born from a 25-year history of advancing exploration projects in

Qualified Person Approval

The scientific and technical information in this news release has been reviewed and approved by Mark Hawksworth, General Manager of the Aura Project, and Jack McPartland of MLI, each of whom is a "qualified person" within the meaning of NI 43-101.

Quality Assurance / Quality Control

Exploration program design, Quality Assurance/Quality Control ("QA/QC") and the interpretation of results is performed by qualified persons employing a QA/QC program consistent with NI 43-101 and industry best practices. For Western Exploration legacy samples, standards and blanks and duplicates were generally included approximately every 20th sample for QA/QC purposes by the Company as well as the lab. Approximately

KLM Geophysics completed a three-line induced polarization & resistivity (IP) survey over the Doby George area in July and August 2023. Oversight of acquisition & processing was done by Western Exploration LLC ("WEX") geologists and R. Ellis acting as consultant to WEX. Data were collected using a pole-dipole (PDP) array with electrode spacing of 200 metres designed to acquire data to depths of 500 metres southwest of the Doby George mineralization. Data processing and editing was done by S. Walker of Campbell & Walker Geophysics Ltd. acting as consultant to KLM Geophysics. 2D inversion modeling was done by S. Walker using the UBC code and by R. Ellis using the Seequent VOXI and Loki Res2DInv codes. The results were comparable although the VOXI and UBC inversion were most similar and are used for interpretation. Targeting comments in this press release are based on recommendations presented by R. Ellis.

Metallurgical Test Work

Interval Preparation and Assay

A total of 431 drill hole interval samples were received for preparation and assay. The samples were whole PQ drill core from nine drill holes (DGC789 through DGC797) with an average length of 2.0 meters. Each interval sample was jaw-crushed to a nominal 50 mm (2 inches) topsize. Crushed intervals were each thoroughly blended by repeated coning and were quartered to obtain a split for finer crushing. Each one-quarter split was crushed to approximately 2 mm in size and was blended and split to obtain 0.3 kg for pulverization. Each 0.3 kg split was pulverized to >

QC samples (blanks and standards) were provided by WEX, with the drill hole interval samples. The blanks were crushed (-19 mm) rock samples, which generally weighed <1 kg each. Those samples were prepared with the corresponding drill interval samples in the order specified by WEX (as reported in the assay certificates). Because of their size and fineness, only the crushing to 2 mm in size, splitting and pulverizing was required for the blanks. The standards were received as assay pulps and were submitted for assay with the drill hole interval assay pulps in the order specified by WEX. MLI internal blanks and standards were also assayed as part of MLI's normal QA/QC protocols.

Interval samples were assayed, using conventional fire assay fusion (30 g)/AA method to determine gold and silver content. Samples that assayed above 10 gAu/mt were reassayed using conventional fire assay fusion (30 g)/gravimetric finish method to determine gold content. All samples that assayed greater than 0.05 gAu/mt were analyzed using a standard cyanide shake analysis procedure to determine gold content. The cyanide solubility procedure used was an ambient, 1 hour shake test at

Column Test Composite Preparation

Once bottle roll test results were reviewed, samples were selected for preparation of seven column test composites. Coarsely crushed (nominal 50 mm) drill interval rejects were combined to produce composites 4838-047 through 4838-053 and 4838-055.

Each of composites 4838-052 and 4838-053 were thoroughly blended by repeated coning and were quartered to obtain appropriately weighted splits, which were combined to produce column test composite 4838-054. Remaining material from composites 4838-052 and 4838-053 was retained for potential future testing.

Each column test composite was thoroughly blended by repeated coning and was quartered to obtain approximately 300 kg for a column leach test (210 kg from Comp. 4838-050, because of sample limitations) and 50 to 75 kg for a head screen analysis. Approximately 95 to 190 kg of each composite was also split for crushing to 12.7 mm in size.

Each split for finer crushing (95 - 190 kg, depending on sample availability) was stage-crushed to

Each head assay split was crushed to minus 2mm in size and was blended and split to obtain

0.3 kg for generation of an assay pulp. Each 0.3 kg sample was pulverized to >

The ore charges did not require agglomeration pretreatment. Lime (0.7 - 2.0 kg/mt) was mixed with the dry ore charges before column loading procedures. Lime additions were based on bottle roll test lime requirements. Ore charges were placed into the 30 cm I.D. (-50mm feeds) or 15 cm I.D. (12.7mm feeds) x 3m (10') high leaching columns in a manner to minimize particle segregation and compaction.

Leaching was conducted by applying cyanide solution (0.5-gram NaCN/Liter) over the ore charges at a rate of 9.6 Liter per hour/m2 (0.004 gallons per minute/ft2) of column cross-sectional area. Pregnant effluent solutions were collected each 24-hour period. Pregnant solution volumes were measured by weighing, and samples were taken for gold and silver analysis using conventional ICP methods. Free cyanide concentration and pH were determined for each pregnant solution. Pregnant solutions were pumped through a three-stage carbon circuit for adsorption of dissolved gold values. Barren solution, with appropriate make-up reagent, was applied to the ore charges daily. After leaching, freshwater rinsing was conducted to remove residual cyanide (county requirement) and to recover dissolved gold values. Moisture required to saturate the ore charges (in process solution inventory), for agglomeration and retained moistures were determined. Apparent ore bulk densities were measured before and after leaching.

Drain down tests were conducted after rinsing was complete. Tests were conducted by terminating solution application, and at that time, measuring drain volume. Drain volumes were collected and measured periodically by weighing until drain down was complete.

After leaching, rinsing, and draining, residues were removed from the columns and moisture samples were taken immediately. Remaining leached residues were air dried, blended and split to obtain a sample for a tail screen analysis. Tail screens were conducted using the same procedures and size fractions as for the head screens to determine residual gold and silver content and distribution, and to obtain recovery by size fraction data. An additional 20 kg split was taken from each 12.7mm feed size column residue for load-permeability testing.

Load-permeability splits were shipped to NewFields in

For additional information on the Aura Project, please see the Technical Report, which has been prepared in accordance with the requirements of NI 43-101, a copy of which is available on SEDAR+ (www.sedarplus.ca) under Western Exploration's issuer profile and on Western Exploration's corporate website (www.westernexploration.com).

Cautionary Statements Regarding Estimates of Mineral Resources

This news release uses the terms measured mineral resources, indicated mineral resources, and inferred mineral resources as a relative measure of the level of confidence in the resource estimate. Readers are cautioned that mineral resources are not mineral reserves and that the economic viability of mineral resources that are not mineral reserves has not been demonstrated. The mineral resource estimate disclosed in this news release may be materially affected by geology, environmental, permitting, legal, title, socio-political, marketing, or other relevant issues. It cannot be assumed that all or any part of the inferred mineral resources will ever be upgraded to the category of indicated mineral resource or measured mineral resource. The mineral resource estimate is classified in accordance with the Canadian Institute of Mining, Metallurgy and Petroleum's "CIM Definition Standards on Mineral Resources and Mineral Reserves" (CIM) incorporated by reference into NI 43-101. Under NI 43-101, estimates of inferred mineral resources may not form the basis of feasibility or pre-feasibility studies or economic studies except for preliminary economic assessments. Readers are cautioned not to assume that further work on the stated resources will lead to mineral reserves that can be mined economically.

Inferred mineral resources have a great amount of uncertainty as to their existence and as to whether they can be mined legally or economically. On October 31, 2018, the

Cautionary Note Regarding Forward-Looking Information

This news release may contain "forward-looking information" and "forward-looking statements" within the meaning of the applicable Canadian and

For additional information with respect to these and other factors and assumptions underlying the forward‐looking statements and forward-looking information made in this news release concerning Western Exploration, please refer to the public disclosure record of Western Exploration, including the management information circular dated November 12, 2021 and the Company's most recent annual and interim financial statements and related management's discussion and analysis, which are available on SEDAR+ (www.sedarplus.ca) under Western Exploration's issuer profile. The forward-looking statements set forth herein concerning Western Exploration reflect management's expectations as at the date of this news release and are subject to change after such date. Western Exploration disclaims any intention or obligation to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, other than as required by law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release. No stock exchange, securities commission or other regulatory authority has approved or disapproved the information contained herein.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240117631768/en/

Darcy Marud

Chief Executive Officer

Telephone: (775) 329-8119

Email: dmarud@westernexploration.com

Nichole Cowles

Investor Relations

Telephone: (775) 240-4172

Email: nicholecowles@westernexploration.com

Source: Western Exploration Inc.

FAQ

What are the highlights of the 2023 metallurgical testing results announced by Western Exploration Inc.?

What were the results of the bottle roll testing and column leach tests conducted by McClelland Laboratories, Inc.?