Twin Vee PowerCats Co. New 5-Axis CNC Router to Harness Advanced Robotics in Production Process

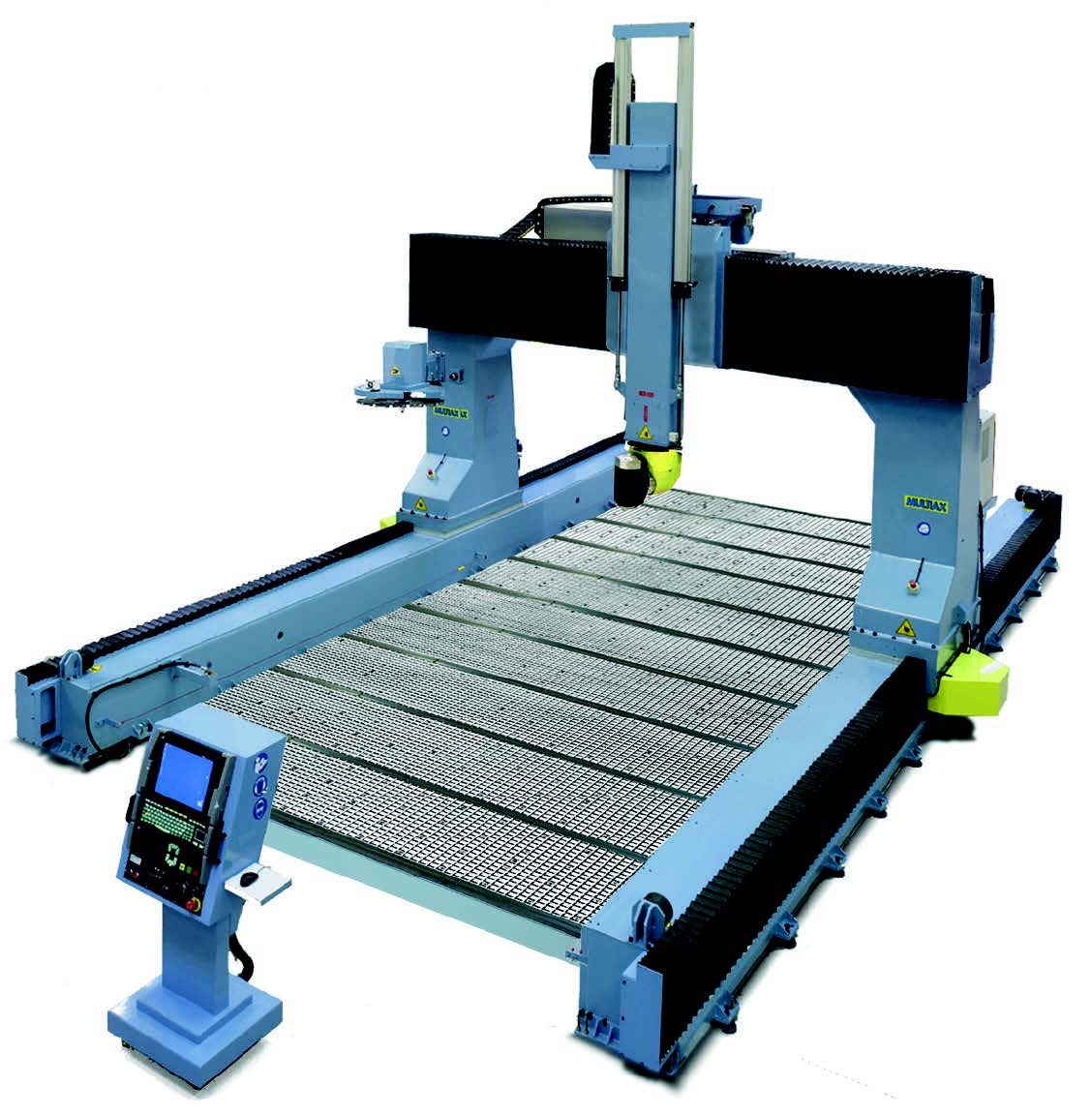

Twin Vee PowerCats (Nasdaq: VEEE) announced the upcoming delivery of a state-of-the-art Multiax L Series 5-axis CNC router to enhance its manufacturing capabilities. This investment will enable the company to bring the tooling of high-quality plugs and molds for new boat models in-house.

CEO Joseph C. Visconti highlighted that the advanced robotics will streamline manufacturing processes, create complex curves and shapes impossible with traditional methods, and improve quality control at their Fort Pierce facility. The company expects this addition to accelerate product development while reducing costs by minimizing reliance on external vendors for tooling.

Twin Vee is also exploring additional robotic solutions to enhance various operational stages, from design and production to quality control and finishing, aiming to improve manufacturing efficiency, reduce waste, and enhance worker safety.

Twin Vee PowerCats (Nasdaq: VEEE) ha annunciato la prossima consegna di un avanzato router CNC a 5 assi della serie Multiax L per migliorare le sue capacità produttive. Questo investimento permetterà all'azienda di portare la produzione di attrezzature per spine e stampi di alta qualità per nuovi modelli di imbarcazioni internamente.

Il CEO Joseph C. Visconti ha sottolineato che la robotica avanzata renderà più efficienti i processi produttivi, consentendo di creare curve e forme complesse impossibili con i metodi tradizionali, e migliorerà il controllo qualità nella loro struttura di Fort Pierce. L'azienda si aspetta che questa aggiunta accelererà lo sviluppo dei prodotti riducendo al contempo i costi, minimizzando la dipendenza da fornitori esterni per le attrezzature.

Twin Vee sta inoltre esplorando soluzioni robotiche aggiuntive per migliorare varie fasi operative, dalla progettazione e produzione al controllo qualità e alla rifinitura, con l'obiettivo di migliorare l'efficienza produttiva, ridurre gli sprechi e aumentare la sicurezza dei lavoratori.

Twin Vee PowerCats (Nasdaq: VEEE) anunció la próxima entrega de un router CNC de 5 ejes de la serie Multiax L de última generación para mejorar sus capacidades de fabricación. Esta inversión permitirá a la empresa realizar internamente las herramientas de enchufes y moldes de alta calidad para nuevos modelos de barcos.

El CEO Joseph C. Visconti destacó que la robótica avanzada agilizará los procesos de fabricación, creará curvas y formas complejas imposibles con métodos tradicionales y mejorará el control de calidad en su instalación en Fort Pierce. La empresa espera que esta adición acelere el desarrollo de productos al tiempo que reduce costos al minimizar la dependencia de proveedores externos para las herramientas.

Twin Vee también está explorando soluciones robóticas adicionales para mejorar diversas etapas operativas, desde el diseño y la producción hasta el control de calidad y el acabado, con el objetivo de mejorar la eficiencia de fabricación, reducir desperdicios y aumentar la seguridad de los trabajadores.

Twin Vee PowerCats (Nasdaq: VEEE)는 첨단 Multiax L 시리즈 5축 CNC 라우터의 도입을 발표하여 제조 능력을 향상시킬 예정입니다. 이 투자는 회사가 새로운 보트 모델에 대한 고품질 플러그와 금형의 도구를 내부에서 제작할 수 있게 해줄 것입니다.

CEO 조셉 C. 비스콘티는 고급 로봇 기술이 제조 공정을 간소화하고 전통적인 방법으로는 불가능한 복잡한 곡선과 형태를 생성하며, 포트 피어스 시설에서 품질 관리를 개선할 것이라고 강조했습니다. 회사는 이 추가 장비가 제품 개발을 가속화하고 외부 공급업체에 대한 의존도를 최소화하여 비용을 절감할 것으로 기대하고 있습니다.

Twin Vee는 설계, 생산, 품질 관리 및 마감 등 다양한 운영 단계를 향상시키기 위해 추가적인 로봇 솔루션을 탐색하고 있으며, 이는 제조 효율성을 개선하고 폐기물을 줄이며 근로자의 안전성을 높이는 것을 목표로 하고 있습니다.

Twin Vee PowerCats (Nasdaq: VEEE) a annoncé la prochaine livraison d'un routeur CNC à 5 axes de la série Multiax L à la pointe de la technologie pour améliorer ses capacités de fabrication. Cet investissement permettra à l'entreprise de fabriquer en interne des outils de prises et de moules de haute qualité pour de nouveaux modèles de bateaux.

Le PDG Joseph C. Visconti a souligné que la robotique avancée rationalisera les processus de fabrication, créera des courbes et des formes complexes impossibles avec des méthodes traditionnelles et améliorera le contrôle qualité dans leur installation de Fort Pierce. L'entreprise prévoit que cet ajout accélérera le développement des produits tout en réduisant les coûts en minimisant la dépendance à l'égard des fournisseurs externes pour les outils.

Twin Vee explore également des solutions robotiques supplémentaires pour améliorer diverses étapes opérationnelles, de la conception et de la production au contrôle qualité et à la finition, dans le but d'améliorer l'efficacité de la fabrication, de réduire les déchets et d'améliorer la sécurité des travailleurs.

Twin Vee PowerCats (Nasdaq: VEEE) hat die bevorstehende Lieferung eines hochmodernen Multiax L Series 5-Achsen CNC-Fräsers angekündigt, um die Fertigungskapazitäten zu erweitern. Diese Investition ermöglicht es dem Unternehmen, die Werkzeuge für hochwertige Stecker und Formen für neue Bootmodelle intern herzustellen.

CEO Joseph C. Visconti hob hervor, dass die fortschrittliche Robotik die Fertigungsprozesse optimieren, komplexe Kurven und Formen schaffen wird, die mit traditionellen Methoden unmöglich sind, und die Qualitätskontrolle in ihrer Einrichtung in Fort Pierce verbessern wird. Das Unternehmen erwartet, dass diese Ergänzung die Produktentwicklung beschleunigt und die Kosten senkt, indem die Abhängigkeit von externen Anbietern für Werkzeuge minimiert wird.

Twin Vee untersucht auch zusätzliche robotische Lösungen zur Verbesserung verschiedener Betriebsphasen, von der Gestaltung und Produktion bis zur Qualitätskontrolle und -veredelung, mit dem Ziel, die Fertigungseffizienz zu steigern, Abfall zu reduzieren und die Sicherheit der Mitarbeiter zu erhöhen.

- Investment in advanced manufacturing technology to reduce production costs

- Reduction in dependency on external vendors for tooling

- Expected acceleration in new product development timeline

- Enhanced quality control and manufacturing precision capabilities

- Significant capital expenditure required for new equipment

- Potential temporary disruption during implementation and training phase

Insights

The acquisition of a 5-axis CNC router represents a strategic vertical integration move that will significantly enhance Twin Vee's manufacturing capabilities. This technology investment addresses three critical business aspects: cost reduction, quality control and time-to-market acceleration.

By bringing mold tooling in-house, Twin Vee can expect a 30-40% reduction in tooling costs typically charged by external vendors. The Multiax L Series' advanced capabilities in creating complex geometries will enable the company to produce more sophisticated hull designs, potentially leading to improved hydrodynamic performance and fuel efficiency in their boats.

For investors, this signals a well-thought-out capital allocation strategy. The ROI on such equipment typically materializes within 18-24 months through reduced outsourcing costs, faster product development cycles and improved quality control. The mention of exploring additional robotic solutions suggests a comprehensive modernization strategy that could position Twin Vee as a technology leader in the powerboat manufacturing sector.

This technological upgrade positions Twin Vee to compete more effectively in the high-end powerboat market segment. The ability to rapidly prototype and modify designs in-house gives the company a significant competitive advantage in responding to market demands and consumer preferences.

The marine industry is experiencing a shift toward more customized and sophisticated vessel designs. Having in-house CNC capabilities allows Twin Vee to potentially capture higher margins by offering more customized options while maintaining better control over production costs. The timing of this investment aligns with industry trends showing increased demand for premium powerboats with complex design features.

Looking at the broader market implications, this move could help Twin Vee capture market share from larger competitors by reducing development cycles and potentially offering more competitive pricing through improved operational efficiency. For a company with a market cap of

FORT PIERCE, FL / ACCESS Newswire / January 21, 2025 / Twin Vee PowerCats Co. (Nasdaq:VEEE) ("Twin Vee" or the "Company"), a manufacturer, distributor, and marketer of power sport boats, today announced the imminent arrival of its new state-of-the-art 5-axis CNC router, a significant investment in the Company's manufacturing capabilities. The Multiax L Series 5-axis CNC router, scheduled for delivery in the coming weeks, will allow the Company to bring the tooling of high-quality plugs and molds necessary for its brand-new boat models in-house.

"Robotics will play a key role in implementing Twin Vee's product development strategy. By integrating this advanced CNC router into our workflow, we'll be able to streamline our manufacturing process and enhance the quality of the boat molds we use to build our products," explains Joseph C. Visconti, CEO of Twin Vee PowerCats Co. "Our new router, with its robotic precision and flexibility, can create complex curves and shapes that would be impossible to achieve with traditional methods. This incredible addition to our Fort Pierce facility will improve the quality of our plugs and molds and provide greater precision and enhanced quality control going forward."

According to Visconti, the 5-axis CNC router will be instrumental in getting Twin Vee's new boat designs to market faster by speeding up product development. Moreover, the Company expects to reduce associated costs and minimize its reliance on external vendors for tooling by bringing in-house the most expensive and time-consuming aspects of boat building.

Twin Vee's incorporation of robotics extends beyond installing its all-new 5-axis CNC router. "The Company is actively exploring other robotic solutions to complement and enhance various stages of our operations, from design and production to quality control and finishing," remarks Visconti. "We want to introduce additional comprehensive platforms, like our CNC router, to our manufacturing processes to help improve manufacturing efficiency, reduce waste, enhance worker safety, and ultimately continue to deliver the "Best Riding Boats on the Water" to our customers."

About Twin Vee PowerCats Co.

Twin Vee PowerCats Co. manufactures Twin Vee and AquaSport boats. The Company produces a range of boats designed for activities including fishing, cruising, and recreational use. Twin Vee PowerCats are recognized for their stable, fuel-efficient, and smooth-riding catamaran hull designs. Twin Vee is one of the most recognizable brand names in the catamaran sport boat category and is known as the "Best Riding Boats on the Water™." The Company is located in Fort Pierce, Florida, and has been building and selling boats for 30 years. Learn more at twinvee.com.

Visit Twin Vee PowerCats Co. on Facebook and Instagram.

Visit AquaSport on Facebook and Instagram.

Check out Joseph's CEO Hustle webcast via Instagram, Facebook, or YouTube.

Forward-Looking Statements

This press release contains certain forward-looking statements within the meaning of the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. These statements are identified by the use of the words "could," "believe," "anticipate," "intend," "estimate," "expect," "may," "continue," "predict," "potential," "project" and similar expressions that are intended to identify forward-looking statements and include statements regarding the arrival of a new Multiax L Series 5-axis CNC router in the coming weeks, bringing the tooling of high-quality plugs and molds necessary for the Company's brand-new boat models in-house, robotics playing a key role in implementing Twin Vee's product development strategy, integrating the CNC router into the Company's workflow to streamline its manufacturing process and enhance the quality of the boat molds used to build its products, using the new router to create complex curves and shapes that would be impossible to achieve with traditional methods, improving the quality of the Company's plugs and molds and providing greater precision and enhanced quality control going forward, the 5-axis CNC router being instrumental in getting Twin Vee's new boat designs to market faster by speeding up product development, reducing associated costs and minimizing the Company's reliance on external vendors for tooling by bringing in-house the most expensive and time-consuming aspects of boat building, actively exploring other robotic solutions to complement and enhance various stages of the Company's operations and introducing additional comprehensive platforms to the Company's manufacturing processes to help improve manufacturing efficiency, reduce waste, enhance worker safety, and ultimately continue to deliver the "Best Riding Boats on the Water" to the Company's customers. These forward-looking statements are based on management's expectations and assumptions as of the date of this press release and are subject to a number of risks and uncertainties, many of which are difficult to predict that could cause actual results to differ materially from current expectations and assumptions from those set forth or implied by any forward-looking statements. Important factors that could cause actual results to differ materially from current expectations include, among others, the Company's ability to bring the tooling of high-quality plugs and molds necessary for the Company's brand-new boat models in-house as planned, the Company's ability to implement its product development strategy, the Company's ability to integrate the CNC router into the Company's workflow to streamline its manufacturing process and enhance the quality of the boat molds used to build its products, the Company's ability to improve the quality of its plugs and molds and provide greater precision and enhanced quality control going forward, the Company's ability to by speed up product development with the CNC router, the Company's ability to reduce associated costs and minimize its reliance on external vendors for tooling by bringing in-house the most expensive and time-consuming aspects of boat building, the Company's ability to identify and implement other robotic solutions to complement and enhance various stages of the Company's operations, the Company's ability to improve manufacturing efficiency, reduce waste, enhance worker safety, and deliver the "Best Riding Boats on the Water" to its customers, and the risk factors described in the Company's Annual Report on Form 10-K for the year ended December 31, 2023, the Company's Quarterly Reports on Form 10-Q, the Company's Current Reports on Form 8-K and subsequent filings with the SEC. The information in this release is provided only as of the date of this release, and the Company undertakes no obligation to update or revise publicly any forward-looking statements, whether as a result of new information, future events or otherwise, after the date on which the statements are made or to reflect the occurrence of unanticipated events, except as required by law.

Contact:

Glenn Sonoda

investor@twinvee.com

SOURCE: Twin Vee PowerCats Co.

View the original press release on ACCESS Newswire