MakerBot Strengthens METHOD Materials Portfolio with New Composites from LEHVOSS Group

MakerBot, a Stratasys company (NASDAQ: SSYS), is expanding its 3D printing materials with three new LUVOCOM® 3F products from LEHVOSS Group. This addition brings the total number of METHOD® materials to 30, enhancing options for engineering applications. The new materials feature high strength and heat resistance, suitable for prototyping and end-use parts. Notably, they provide enhanced performance characteristics, such as reduced warpage and excellent surface finish, improving the overall 3D printing experience.

- Addition of three new advanced materials to the MakerBot METHOD platform, totaling 30 materials available.

- New materials offer high strength, heat resistance, and minimized warping, enhancing engineering applications.

- Materials optimized for printing ease, improving product quality in prototyping and end-use applications.

- None.

Insights

Analyzing...

Available through MakerBot LABS, the newly-qualified 3D printing materials are ideal for demanding engineering applications that require high strength and heat resistance

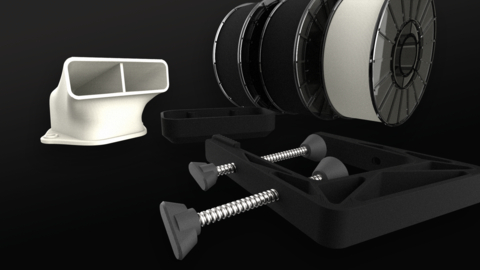

LEHVOSS Group LUVOCOM 3F materials now available to print on the MakerBot METHOD 3D printing platform (Photo: Business Wire)

LUVOCOM 3F PAHT 9825 NT, LUVOCOM 3F PAHT CF 9891 BK, and LUVOCOM 3F PET CF 9780 BK are available to use with the MakerBot LABS GEN 2 Experimental Extruder1 for both the METHOD and METHOD X 3D printers. The LABS extruder transforms METHOD into an open platform that is able to print qualified advanced engineering materials from leading filament suppliers.

Designed for 3D printing and industrial applications, the LUVOCOM 3F materials have similar properties to their compounded versions used for injection molding. These materials are specially optimized to provide an easy-to-print experience and to achieve the next level of properties and quality. Parts printed with these materials result in strong, stiff prints with a high-quality surface finish, and are ideal for prototyping, jigs and fixtures, and end-use applications.

“The MakerBot METHOD and METHOD X machines offer unique heated chamber capabilities which allow semi-crystalline materials to have their full properties out of the printer, avoiding the need of post-processes. In addition, its excellent precision and reproducibility in combination with our high-performance LUVOCOM 3F material range brings an exceptional engineering performance to the customers,” said

“We are always evaluating new materials to meet the needs of our customers and their applications. The ability to 3D print additional high-performance materials on the METHOD platform opens more opportunities for those who want to test out different materials with advanced mechanical and thermal properties,” said

The qualified LUVOCOM 3F materials include:

-

LUVOCOM 3F PAHT 9825 NT – A high-temperature polyamide (also known as nylon) material with continuous service temperature of up to 100°C and the strength of PA/Nylon 6. The material has

50% reduced water uptake and a four-times slower absorption rate compared to PA62. Low moisture absorption can help minimize printing issues as well as property changes of the printed part. This material is optimized for low warpage, high strength and impact resistance, and excellent surface finish for end-use parts, such as flanges and fixtures. -

LUVOCOM 3F PAHT CF 9891 BK – The

carbon fiber (CF) filled grade of LUVOCOM 3F PAHT 9825 NT has even lower water uptake and good resistance against harsh chemicals like automotive fluids. The addition ofcarbon fiber strengthens the thermal and mechanical properties, and has a continued use of up to 150°C while retaining50% of its mechanical properties3. The material is suitable for high temperature environments such as automotive under-the-hood applications, such as housings or engine covers. In addition to its outstanding mechanical performance, the material is easy to print and does not warp. -

LUVOCOM 3F PET CF 9780 BK – A

carbon fiber-filled polyethylene terephthalate (PET) material that is easy to print, with low warping, and exhibits a superb surface finish straight from the printer, reducing the need for post-processing. It provides high strength, elevated temperature resistance up to 120°C and chemical resistance outperforming PETG4.

As the only 3D printer in its price class with a heated chamber that can print composites, polymers, and metals—all on one machine, METHOD brings a unique 3D printing experience to users. METHOD’s heated chamber controls the 3D printing process to allow each layer to cool down simultaneously to minimize warping and curling. This allows it to print parts with advanced materials more successfully than typical desktop 3D printers.

For more information, visit makerbot.com/method.

LUVOCOM 3F materials can be purchased through authorized

About MakerBot

MakerBot, a

MakerBot, MakerBot LABS, MakerBot METHOD, METHOD, MakerBot METHOD X, and METHOD X, are trademarks or registered marks of

___________________________

1 The MakerBot LABS Experimental Extruder for METHOD is an experimental product and is not covered under limited warranty or MakerCare.

2 Based on data provided by

3 Based on data provided by

4 Based on data provided by

View source version on businesswire.com: https://www.businesswire.com/news/home/20220120005629/en/

Press Contact

MakerBot

bennie.sham@makerbot.com

Source: MakerBot