Rexnord Launches the Only Universal Smart Condition Monitoring System Capable of Monitoring Oil Quality, Temperature and Vibration on Most Large Gear Drives

Rexnord Process & Motion Control (PMC) has launched the 1030 Smart Condition Monitoring System, designed to enhance efficiency in large gear drives. This innovative system continuously tracks oil quality, temperature, and vibration, offering notable benefits such as reduced maintenance costs and improved uptime. It is compatible with gear drives having an oil port of 3/4” or larger and is suited for demanding industries such as mining and power generation. The system allows for easy remote monitoring and integration with existing infrastructure, promoting safety and reducing equipment inspections.

- Proven maintenance savings through demand-based oil changes.

- Enhanced safety by minimizing hands-on equipment inspections.

- Increased uptime via cost-effective preventive maintenance.

- Easy integration with existing programmable logic controllers (PLCs).

- Potential reduction in spare units needed on-site.

- None.

Rexnord Process & Motion Control (PMC) introduced today the latest addition to its line of Smart Condition Monitoring Systems—the new 1030. This universal model continuously monitors large gear drives for oil quality, temperature and vibration to improve uptime, cost efficiency and safety.

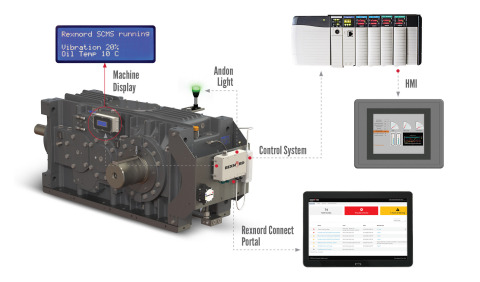

How Our Smart Condition Monitoring System Works (Graphic: Business Wire)

The 1030 can be fitted to nearly any gear drive with an oil port 3/4” or greater—typically on equipment with a 100 HP or larger motor, commonly used in mining, paper, cement, power and forestry industries. It delivers simple, robust 24/7 remote monitoring of critical assets to optimize total operating costs. Quick installation can be completed by end users, authorized service shops or by a Rexnord technician. Rexnord provides training materials for reference.

“This is a comprehensive solution for customers with multiple brands of large gear drives, and can be used throughout your facility,” said Dan Plach, Rexnord PMC director of digital solutions.

Key benefits include:

- Proven maintenance savings, enabling demand-based oil changes, reducing the need for scheduled maintenance.

- Increased safety, minimizing hands-on equipment inspections in challenging locations.

- Improved uptime, avoiding asset failures through cost effective preventive maintenance.

- Easy integration, with programmable logic controllers (PLCs), allowing end users to quickly initiate remote monitoring via EtherNet/IP®, Modbus® TCP/IP or PROFINET® standards.

The Smart Condition Monitoring System has been engineered with proprietary algorithms to allow continuous monitoring, enabling maintenance managers to easily compare sensor data against models of healthy gear drive operating conditions. Abnormal conditions trigger automated alerts to onsite Andon lights, the PLC control system, and the Rexnord Connect Portal, delivering early warnings to clients that significantly improve uptime. The system puts data in context, enabling customers to focus on outcomes; teams know what action to take when and why.

“The 1030 is the only universal large gear drive solution with oil quality, temperature and vibration monitoring capabilities,” Plach said. “It tracks the humidity level as well as oil quality over time.” Customers know when to change oil or do preventive maintenance, better managing manpower and budget while avoiding unplanned downtime. Having the 1030 system in place may also reduce the number of spare units facilities need to keep on hand in case of breakages, freeing up much-needed space and budget, allowing customers to be more agile.

Condition-based maintenance and remote monitoring also positively impact facility safety. With smart condition monitoring systems in place, the number of hands-on equipment inspections can be reduced, lessening the burden on end users. This is especially important for sites located in harsh environments and areas where equipment is not easily accessible.

Customers in mining, pulp & paper, cement & aggregate, power generation, forestry and other industries with demanding environments can capture significant benefits with the Smart Condition Monitoring System. Rexnord offers scalable options to fit specific applications. Future enhancements to Model 1030 will include the addition of auxiliary sensors.

Customers can purchase the new 1030 on Rexnord.com: https://rxn.bz/3x8jbfa

Additional information is available at the following links:

- Schedule a live demo with a member of the Rexnord team: https://rxn.bz/2SSQ6p3

- Access videos, photos and more: https://rxn.bz/3pnPofu

- Contact connect.support@rexnord.com for information on upgrading your current Rexnord Smart Condition Monitoring System

- Learn about installation: https://rxn.bz/357EiCh

- Find authorized service shops: https://rxn.bz/3pkD1AU

About Rexnord Process & Motion Control (PMC)

Within Rexnord, we design, manufacture, market and service specified, highly engineered mechanical components worldwide used within complex systems where our customers’ reliability requirements and the cost of failure or downtime are extremely high. We keep industry moving with products and services that enhance the reliability of equipment supporting key industries, including food, beverage & liquid, automotive, energy, and mining. Our digital productivity platform, DiRXN (pronounced “Direction”), based on the integration of innovative Industrial Internet of Things (IIoT) and e-commerce technologies with a leading portfolio of tools, products and services, connects our customers to data and information that allows them to optimize productivity across all stages of their lifecycles.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210609005883/en/

FAQ

What is the new product launched by Rexnord PMC?

What industries can benefit from the 1030 Smart Condition Monitoring System?

How does the 1030 system improve equipment maintenance?

What features does the 1030 offer for monitoring?

When was the 1030 Smart Condition Monitoring System introduced?