Lifezone Metals Announces Two-Phased Development Plan for the Kabanga Nickel Project in Tanzania

1.7 Mtpa Phase 1 plus 1.7 Mtpa Phase 2 Expansion for Total 3.4 Mtpa Base Case in the Definitive Feasibility Study

Kabanga Definitive Feasibility Study Remains On-Track for Completion by the End of Q3 2024

Extensive and Ongoing Metallurgical Test Work Demonstrates High Nickel, Copper and Cobalt Recoveries

Kahama Hydromet Refinery Receives its Environmental Impact Assessment Certificate

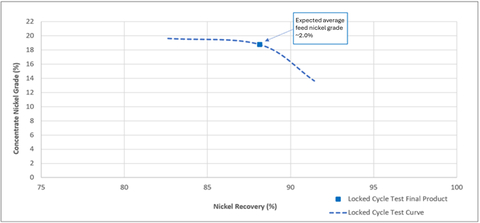

Figure 1: Early Years Blend Composite locked-cycle flotation test work showing concentrate nickel grade versus. nickel recovery. Source: Bureau Veritas Minerals Pty Ltd, Project No. 4668, Locked Cycle Test 2 (LCT2 EYBC). The Locked Cycle Test final product result is based on the average performance of cycles 4 to 6 of the test, at steady state. The Locked Cycle Test curve is derived from the rougher concentrate only and the high-grade concentrate streams of the same test for the same cycles 4 to 6. The curve also reflects and is validated by the open-cycle testing results on the same Early Years Blend Composite sample.

Lifezone Metals has determined that a two-phase development plan for its Kabanga Nickel Project will form the base case of the Definitive Feasibility Study. Design work and mine planning to-date supports an expected 3.4 million tonnes per year operation in the aggregate, comprised of a 1.7 million tonne per year Phase 1 and an additional 1.7 million tonne per year Phase 2 expansion.

The Company continues to collaborate closely with its project partner on this two-phased development plan, as well as numerous other Definitive Feasibility Study work streams. Lifezone Metals is working to evolve and integrate sustainability across Project planning, implementation and in-country operational readiness.

The Kabanga Nickel Project Definitive Feasibility Study, which evaluates the technical specifications and economic business case of the Kabanga Underground Nickel-Copper-Cobalt Mine, Kabanga Concentrator and Kahama Hydromet Refinery, is a work-in-progress and mine planning continues, including the application of modifying factors to establish the economic viability of Mineral Reserves, with various major capital items tendered. The study remains on track for completion by the end of Q3 2024.

Mr. Showalter stated: “We have made solid progress advancing the Kabanga Definitive Feasibility Study, which is progressing both on-time and on-budget, with activities occurring across various countries (

Separate programs of extensive metallurgical testing continue in support of process designs for 1) the Kabanga Concentrator and 2) the Kahama Hydromet Refinery.

Kabanga Concentrator Test Work Achieves High Nickel Recovery of

Kabanga Concentrator test work conducted on a range of variability composite samples sourced from the 2023 drilling program, representative of massive sulfide and ultramafic lithology types from the Kabanga North and Tembo zones (refer to Lifezone’s December 7, 2023 news release), has demonstrated high recoveries of nickel, copper and cobalt to concentrate.

The fully optimized locked-cycle test on an Early Years Blend Composite (“EYBC”; a composite sample that is expected to be a representative average of the first years of production from Kabanga) with a feed grade of

This test has confirmed the historical pilot-plant results and is also in good agreement with the recovery potential as indicated from mineralogy. Lifezone Metals considers these recoveries to be excellent, the high concentrate grades present an exceptional refinery feed with low levels of deleterious elements. Further variability test work on freshly drilled core intervals was initiated in January 2024 and is currently underway to test variation in lithology.

Historical test work included bench scale, batch open-circuit and locked-cycle flotation test work and two continuous pilot-plant test campaigns. Additional test work in support of the concentrator design for the Kabanga Definitive Feasibility Study has been completed at the Bureau Veritas Laboratory in

Over 120 bench-scale, batch open-circuit flotation tests, 116 bench-scale, bulk open-circuit flotation tests and one fully optimized locked-cycle test have been undertaken to date in the current phase of work.

Kahama Hydromet Refinery Test Work Shows that High Recoveries to Finished Metals are Achievable within Short Timeframes

Test work in support of the Kahama Hydromet Refinery design, using Lifezone’s Hydromet Technology, for the Kabanga DFS is continuing at Lifezone’s Laboratory in

Definitive Feasibility Study refinery flowsheet test work undertaken to date includes over 164 bench-scale, batch open-circuit tests and 73 bench-scale locked-cycle tests, incorporating pressure oxidation, solid-liquid separation, neutralization, upgrading and purification processing units. The work has been conducted on a range of concentrate samples generated from the flotation program, representative of massive sulfide and ultramafic lithology types from the North and Tembo zones. The objective is to characterize the unit process responses, support flowsheet design parameters and generate bulk samples for materials handling, paste fill and residue characterization test work.

Concentrate produced from grade-optimized bulk flotation test work was used for hydrometallurgical testing in support of process design, comprising North Deep massive sulfide with mining dilution and grading approximately

Locked cycle pressure oxidation – neutralization test work to track and demonstrate metal and impurity deportment is ongoing, along with further optimization of solvent extraction parameters.

Process design, procurement and fabrication activities are currently underway for a semi-continuous pilot-plant testing concentrate derived from Early Years Blend Composite for confirmation of process design criteria for the Kahama refinery treating the Kabanga nickel sulfide concentrate.

The Kahama Hydromet Refinery Receives its Environmental Impact Assessment Certificate from the Government of

Lifezone has received the Environmental Impact Assessment certificate of approval for the establishment and operation of the Kahama Hydromet Refinery. This important milestone reflects the hard work and dedication of Lifezone’s environmental team.

Safety remains the Top Priority at Kabanga

Lifezone operates with safety as an ongoing, front of mind initiative at every level, and has recorded more than 1.7 million hours worked without a lost time injury at the Kabanga Nickel Project.

In addition, there have been zero environmental incidents year-to-date.

Qualified Persons

Scientific and technical information in this news release has been reviewed and approved by Dr. Mike

If you would like to sign up for Lifezone Metals news alerts, please register here.

About Lifezone Metals

At Lifezone Metals (NYSE: LZM), our mission is to provide cleaner and more responsible metals production and recycling. Using a scalable platform underpinned by our Hydromet Technology, we offer lower energy, lower emission and lower cost metals production compared to traditional smelting.

Our Kabanga Nickel Project in

Through our US-based, platinum, palladium and rhodium recycling joint venture, we are working to demonstrate that our Hydromet Technology can process and recover platinum group metals from responsibly sourced spent automotive catalytic converters in a cleaner and more efficient way than conventional smelting and refining methods.

Cautionary Statement

The Definitive Feasibility Study is a work-in-progress and mine planning continues, including the application of modifying factors to establish the economic viability of Mineral Reserves. Information provided in this news release is current at the date of this release and may be subject to change as the Definitive Feasibility Study progresses.

Forward-Looking Statements

Certain statements made herein are not historical facts but may be considered “forward-looking statements” within the meaning of the Securities Act of 1933, as amended, the Securities Exchange Act of 1934, as amended and the “safe harbor” provisions under the Private Securities Litigation Reform Act of 1995 regarding, amongst other things, the plans, strategies, and prospects, both business and financial, of Lifezone Metals Limited and its subsidiaries and/or affiliates.

Forward-looking statements generally are accompanied by words such as “believe,” “may,” “will,” “estimate,” “continue,” “anticipate,” “intend,” “expect,” “should,” “would,” “plan,” “predict,” “potential,” “seem,” “seek,” “future,” “outlook” or the negatives of these terms or variations of them or similar terminology or expressions that predict or indicate future events or trends or that are not statements of historical matters; provided that the absence of these does not mean that a statement is not forward-looking. These forward-looking statements include, but are not limited to, statements regarding future events, the estimated or anticipated future results of Lifezone Metals, future opportunities for Lifezone Metals, including the efficacy of Lifezone Metals’ hydrometallurgical technology (Hydromet Technology) and the development of, and processing of mineral resources at, the Kabanga Project, and other statements that are not historical facts.

These statements are based on the current expectations of Lifezone Metals’ management and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on, by any investor as a guarantee, an assurance, a prediction or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of Lifezone Metals and its subsidiaries. These statements are subject to a number of risks and uncertainties regarding Lifezone Metals’ business, and actual results may differ materially. These risks and uncertainties include, but are not limited to: general economic, political and business conditions, including but not limited to the economic and operational disruptions; global inflation and cost increases for materials and services; reliability of sampling; success of any pilot work; capital and operating costs varying significantly from estimates; delays in obtaining or failures to obtain required governmental, environmental or other project approvals; changes in government regulations, legislation and rates of taxation; inflation; changes in exchange rates and the availability of foreign exchange; fluctuations in commodity prices; delays in the development of projects and other factors; the outcome of any legal proceedings that may be instituted against the Lifezone Metals; our ability to obtain additional capital, including use of the debt market, future capital requirements and sources and uses of cash; the risks related to the rollout of Lifezone Metals’ business, the efficacy of the Hydromet Technology, and the timing of expected business milestones; the acquisition of, maintenance of and protection of intellectual property; Lifezone’s ability to achieve projections and anticipate uncertainties relating to our business, operations and financial performance, including: expectations with respect to financial and business performance, financial projections and business metrics and any underlying assumptions; expectations regarding product and technology development and pipeline; the effects of competition on Lifezone Metals’ business; the ability of Lifezone Metals to execute its growth strategy, manage growth profitably and retain its key employees; the ability of Lifezone Metals to reach and maintain profitability; enhancing future operating and financial results; complying with laws and regulations applicable to Lifezone Metals’ business; Lifezone Metals’ ability to continue to comply with applicable listing standards of the NYSE; the ability of Lifezone Metals to maintain the listing of its securities on a

The foregoing list of risk factors is not exhaustive. There may be additional risks that Lifezone Metals presently does not know or that Lifezone Metals currently believes are immaterial that could also cause actual results to differ from those contained in forward-looking statements. In addition, forward-looking statements provide Lifezone Metals’ expectations, plans or forecasts of future events and views as of the date of this communication. Lifezone Metals anticipates that subsequent events and developments will cause Lifezone Metals’ assessments to change. However, while Lifezone Metals may elect to update these forward-looking statements in the future, Lifezone Metals specifically disclaims any obligation to do so.

These forward-looking statements should not be relied upon as representing Lifezone Metals’ assessments as of any date subsequent to the date of this communication. Accordingly, undue reliance should not be placed upon the forward-looking statements. Nothing herein should be regarded as a representation by any person that the forward-looking statements set forth herein will be achieved or that any of the contemplated results in such forward-looking statements will be achieved. You should not place undue reliance on forward-looking statements in this communication, which are based upon information available to us as of the date they are made and are qualified in their entirety by reference to the cautionary statements herein. In all cases where historical performance is presented, please note that past performance is not a credible indicator of future results.

Except as otherwise required by applicable law, we disclaim any obligation to publicly update or revise any forward-looking statement to reflect changes in underlying assumptions or factors, new information, data, or methods, future events, or other changes after the date of this communication, except as required by applicable law.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240226757968/en/

Investor Relations –

Evan Young

SVP: Investor Relations & Capital Markets

evan.young@lifezonemetals.com

Investor Relations –

Ingo Hofmaier

Chief Financial Officer

ingo.hofmaier@lifezonemetals.com

Media Enquiries

David Petrie

Manager: Corporate Communications

david.petrie@lifezonemetals.com

Source: Lifezone Metals