Case Study: Leading the Way With Circularity

International Paper (IP) demonstrates its commitment to circular economy principles through its Vision 2030 goals, aiming for 100% responsible fiber sourcing and fully reusable, recyclable, and compostable products. The company uses five million tons of recovered fiber annually, making it one of the world's largest recovered fiber users, while diverting nearly 50% of manufacturing waste from landfills.

IP has made significant progress in sustainability, replacing 765 tons of plastics with corrugated products in EMEA during 2022. The company processes over 7 million tons of fiber annually, representing 12% of the U.S. recycled cardboard market. IP has increased OCC recovery by 60% since 2010 and utilizes ForSite™, an advanced fiber procurement mapping tool, to ensure responsible sourcing practices.

International Paper (IP) dimostra il suo impegno verso i principi dell'economia circolare attraverso i suoi obiettivi Vision 2030, mirati a ottenere il 100% di approvvigionamento di fibre responsabili e prodotti completamente riutilizzabili, riciclabili e compostabili. L'azienda utilizza annualmente cinque milioni di tonnellate di fibre ricuperate, diventando uno dei più grandi utilizzatori di fibre ricuperate al mondo, mentre devia quasi il 50% dei rifiuti di produzione dalle discariche.

IP ha fatto significativi progressi nella sostenibilità, sostituendo 765 tonnellate di plastica con prodotti in cartone ondulato nell'EMEA nel 2022. L'azienda elabora oltre 7 milioni di tonnellate di fibre annualmente, rappresentando il 12% del mercato del cartone riciclato negli Stati Uniti. IP ha aumentato il recupero di OCC del 60% dal 2010 e utilizza ForSite™, uno strumento avanzato di mappatura per l'approvvigionamento di fibre, per garantire pratiche di approvvigionamento responsabili.

International Paper (IP) demuestra su compromiso con los principios de la economía circular a través de sus objetivos Vision 2030, que buscan un 100% de aprovisionamiento de fibra responsable y productos completamente reutilizables, reciclables y compostables. La empresa utiliza anualmente cinco millones de toneladas de fibra recuperada, convirtiéndose en uno de los mayores usuarios de fibra recuperada del mundo, mientras desvía casi el 50% de los residuos de fabricación de los vertederos.

IP ha logrado avances significativos en sostenibilidad, reemplazando 765 toneladas de plásticos con productos de cartón ondulado en EMEA durante 2022. La empresa procesa más de 7 millones de toneladas de fibra anualmente, representando el 12% del mercado de cartón reciclado en los EE. UU. IP ha aumentado la recuperación de OCC en un 60% desde 2010 y utiliza ForSite™, una herramienta avanzada de mapeo de aprovisionamiento de fibra, para garantizar prácticas de aprovisionamiento responsables.

International Paper (IP)는 2030 비전을 통해 순환 경제 원칙에 대한 약속을 보여줍니다. 이 목표는 100% 책임 있는 섬유 소싱과 완전히 재사용 가능하고 재활용 가능하며 퇴비화 가능한 제품을 목표로 합니다. 이 회사는 연간 500만 톤의 회수된 섬유를 사용하여 세계에서 가장 큰 회수된 섬유 사용자 중 하나가 되었으며, 제조 폐기물의 거의 50%를 매립지로부터 방향을 틀고 있습니다.

IP는 2022년 동안 EMEA에서 플라스틱 765톤을 골판지 제품으로 대체하는 등 지속 가능성에서 중요한 발전을 이루었습니다. 이 회사는 매년 700만 톤 이상의 섬유를 가공하고 있으며, 이는 미국 재활용 골판지 시장의 12%를 차지합니다. IP는 2010년 이후 OCC 회수를 60% 증가시켰고, 책임 있는 소싱 관행을 보장하기 위해 고급 섬유 조달 매핑 도구인 ForSite™를 활용하고 있습니다.

International Paper (IP) démontre son engagement envers les principes de l'économie circulaire à travers ses objectifs Vision 2030, visant un approvisionnement en fibres 100% responsable et des produits entièrement réutilisables, recyclables et compostables. L'entreprise utilise cinq millions de tonnes de fibres récupérées chaque année, ce qui en fait l'un des plus grands utilisateurs de fibres récupérées au monde, tout en détournant près de 50% des déchets de fabrication des décharges.

IP a réalisé des progrès significatifs en matière de durabilité, remplaçant 765 tonnes de plastiques par des produits en carton ondulé dans la région EMEA en 2022. L'entreprise traite plus de 7 millions de tonnes de fibres par an, représentant 12% du marché américain du carton recyclé. IP a augmenté la récupération de l'OCC de 60% depuis 2010 et utilise ForSite™, un outil avancé de cartographie de l'approvisionnement en fibres, pour garantir des pratiques d'approvisionnement responsables.

International Paper (IP) zeigt sein Engagement für die Prinzipien der Kreislaufwirtschaft durch seine Vision 2030-Ziele, die auf eine 100% verantwortungsvolle Faserbeschaffung und vollständig wiederverwendbare, recycelbare und kompostierbare Produkte abzielen. Das Unternehmen verwendet jährlich fünf Millionen Tonnen recycelte Faser und gehört zu den größten Nutzern recycelter Faser weltweit, während es fast 50% des Produktionsabfalls von Deponien ableitet.

IP hat erhebliche Fortschritte in der Nachhaltigkeit erzielt, indem es im Jahr 2022 in der EMEA-Region 765 Tonnen Kunststoff durch Wellpappeprodukte ersetzt hat. Das Unternehmen verarbeitet jährlich über 7 Millionen Tonnen Faser, was 12% des amerikanischen Marktes für recycelte Pappe ausmacht. IP hat die OCC-Rückgewinnung seit 2010 um 60% erhöht und setzt ForSite™, ein fortschrittliches Faserbeschaffungs-Tool, ein, um verantwortungsvolle Beschaffungspraktiken zu gewährleisten.

- Processes over 7 million tons of fiber annually (12% of U.S. recycled cardboard market)

- Increased OCC recovery by 60% since 2010

- Replaced 765 tons of plastics with corrugated products in EMEA (2022)

- Diverts nearly 50% of manufacturing waste from landfills

- Utilizes 5 million tons of recovered fiber annually

- None.

NORTHAMPTON, MA / ACCESSWIRE / December 16, 2024 / International Paper Company

Originally published in International Paper's *Thinking Inside the Box* white paper

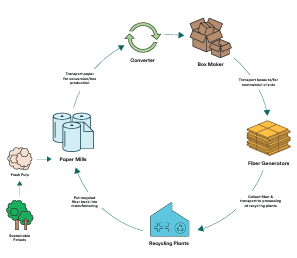

International Paper implements circular principles and practices throughout its value chain to ensure that its products are responsibly sourced, recovered and recycled into new boxes.

The company's Vision 2030 goals align with the principles of the circular economy - and its actions demonstrate a commitment to progress and growth in the sustainability space. By 2030, IP aims to source

Setting measurable sustainability goals helps packaging companies align to the principles of a circular economy: to eliminate waste and pollution, circulate products and materials and regenerate nature.

Eliminate Waste and Pollution

Much of the world economy operates in a way that converts raw materials to products and then eventually disposes these products as waste. Waste accumulates and becomes unusable. At the same time, landfills are one of the largest producers of GHG emissions. Circular economic thinking treats waste as a "design flaw"20, which can be mitigated and eventually solved through adaptations to the use and reuse of products.

Responsible use of natural resources and transparency in sourcing are essential to meeting increased demand for wood fiber without destroying valuable forests. The recovery and recycling of fiber-based products is integral to "reducing consumption footprints, providing sustainable products and thereby contributing to creating more sustainable lifestyles."21

A core component of any circularity strategy are products that enjoy multiple lives through repeated cycles of reuse, recovery and recycling, and the assurance that any byproducts of the manufacturing process are put to good use. Every year, IP uses five million tons of recovered fiber to make new fiber-based packaging, making International Paper one of the world's largest users of recovered fiber. Additionally, nearly

In International Paper's Europe, Middle East and Africa (EMEA) region, the company is promoting sustainable and renewable products by developing solutions for all types of packaging. As a result of these efforts in EMEA, IP's corrugated products have replaced 765 tons of plastics in 2022, and 1,410 tons replaced since the beginning of the decade.

Circulate Products and Materials

International Paper occupies a unique position in the market as both a producer of fiber-based products and a consumer of reclaimed cardboard. As such, the company has a marked impact on the overall industry for recycled cardboard.

There are few products in the world where a used product can generate revenue, but cardboard is one. In the customer success story below, International Paper was able to solve the customer's challenges created by China's withdrawal from the import waste market, generate revenue from would-be waste product, and close the circularity loop in its sustainable packaging story.

A national wholesaler was faced with the challenge of needing to diversify its recycling partners. A single distribution center uses tens of thousands of tons of cardboard each year. Without an outlet, its used cardboard would accumulate on its loading docks and in its parking lots, impeding business, creating a fire hazard and otherwise threatening human safety. As both an aggregator and manufacturer, International Paper offered end-to-end circularity. International Paper has a nationwide network of 18 recycling plants to handle the old corrugated containers (OCC) volume produced by a national wholesaler of this scale. IP also had the transportation infrastructure to step in from day one and guarantee movement of

Another example of a circular customer solution comes from Italy where IP collaborated with long-standing customer Colgate-Palmolive to design a circular supply chain solution to decrease waste and increase recycling. A local transport company collects paper and corrugated packaging scraps from the Colgate-Palmolive plant and delivers them to a local recycled paper manufacturing facility. IP's Pomezia, Italy box plant then transforms it into the Circular Box, which is used for transporting personal care products. The result is a closed and sustainable circular supply chain. The Circular Box was chosen as a finalist in the Best Packaging 2022 contest, organized by the Italian Packaging Institute (Istituto Italiano Imballagio) in collaboration with Conai (National Packaging Consortium).22

Positively Impact Nature

1.6 billion people worldwide depend on healthy forests for their livelihoods.23 Because the creation of paper-based products begins in the forest, packaging companies should be committed to using only fiber from sustainably managed forests, as well as recovered fiber.

It all starts with responsible and transparent sourcing. At IP, the fiber supply team has developed an internal fiber procurement mapping tool called ForSite™, an industry-leading platform that exemplifies transparency, risk mitigation and targeted collaboration. ForSite™ enables IP to know where its wood is coming from and ensures that the right resources and decisions are made before the fiber enters the mill system.

This system guides IP‘s responsible fiber procurement on non-certified forestland in the U.S. It ensures that conservation approaches, similar to those practiced on third-party certified lands, are incorporated in forest management and harvest practices on non-certified lands.

ForSite™ uses Geographic information system (GIS) technology to display and organize spatial data within the complex network of family-owned and institutional "stands" that make up the forests where IP procures its fiber. ForSite™ data includes an array of environmental and spatial attributes, including rare, threatened and endangered species, priority forest types and landscapes, soil types, topography and hydrology, satellite imagery and optimized delivery location. This data is presented in an easy-to-use mobile app, which allows fiber supply team members to make informed decisions prior to the fiber entering IP's supply chain. In addition, ForSite™ assists partners in the tree farming industry and conservation groups.

By knowing the exact location of the direct fiber purchased, IP can ensure not only that its fiber is derived from sustainably managed forests, but also that it is delivered to the most cost-effective facility.

As one of the world's leading producers of renewable, fiber-based packaging, International Paper uses new pulp from sustainably managed forests, and millions of tons of used cardboard, which is processed into new boxes. It is this end-to-end circular model that sets IP's approach apart from almost every other cardboard recycler.

International Paper works at every level of the circular economy to improve recovery and recycling of fiber; it is critical to its entire business. IP makes about one of every three cardboard boxes used in the United States, and on average, a third of the fiber in any given box is recycled. As such, International Paper is one of the largest buyers of used cardboard globally. The company recovers, processes, buys or facilitates the sale of more than 7 million tons of fiber every year. That is

The current rate of recovered fiber is high: nearing

About International Paper

International Paper (NYSE:IP) is a global producer of sustainable packaging, pulp and other fiber-based products, and one of the world's largest recyclers. Headquartered in Memphis, Tenn., we employ approximately 39,000 colleagues globally who are committed to creating what's next. We serve customers worldwide, with manufacturing operations in North America, Latin America, North Africa and Europe. Net sales for 2023 were

About International Paper - EMEA

In Europe, Middle East & Africa (EMEA), International Paper focuses on the production and marketing of fiber-based packaging and specialty pulp, employing approximately 4,400 people. As a leading supplier of high-quality corrugated containers for a multitude of applications, we serve customers throughout the region from our network of two recycled containerboard mills and 23 box plants in France, Italy, Morocco, Portugal and Spain. Specialty pulp is made in Gdansk, Poland. Other products available from International Paper in the region include a variety of Kraft linerboard and other pulp products.

Contact Info:

Spokesperson: International Paper Company

Website: https://www.3blmedia.com/profiles/international-paper-company

Email: info@3blmedia.com

SOURCE: International Paper Company

View the original press release on accesswire.com