Understanding VOC Emissions: Importance of Reduction and Cummins' Progress

Cummins Inc. reports significant progress in reducing Volatile Organic Compounds (VOC) emissions, achieving a 35% reduction as of 2023 towards their 2030 goal of 50% reduction from 2018 levels. Over 70% of the company's VOC emissions come from painting and coating processes. The company implements various reduction strategies including: eliminating paint usage where possible, switching to waterborne paints, and optimizing painting processes. Notable achievements include a 69% VOC reduction at the Daventry Engine Plant and development of new paint filters at Jamestown Engine Plant reducing waste by 30%. The Darlington Engine Plant aims for 70% VOC reduction through water-based paint conversion.

Cummins Inc. riporta progressi significativi nella riduzione delle emissioni di Composti Organici Volatili (COV), raggiungendo una riduzione del 35% nel 2023 verso l'obiettivo del 50% entro il 2030 rispetto ai livelli del 2018. Oltre il 70% delle emissioni di COV dell'azienda proviene dai processi di pittura e rivestimento. L'azienda attua varie strategie di riduzione tra cui: eliminare l'uso della vernice dove possibile, passare a vernici a base d'acqua e ottimizzare i processi di verniciatura. Tra i risultati notevoli ci sono una riduzione del 69% dei COV presso il Daventry Engine Plant e lo sviluppo di nuovi filtri per vernici presso il Jamestown Engine Plant che riducono i rifiuti del 30%. Il Darlington Engine Plant punta a una riduzione del 70% dei COV attraverso la conversione a vernici a base d'acqua.

Cummins Inc. informa sobre avances significativos en la reducción de emisiones de Compuestos Orgánicos Volátiles (COV), logrando una reducción del 35% en 2023 hacia su objetivo de reducirlas en un 50% para 2030 en comparación con los niveles de 2018. Más del 70% de las emisiones de COV de la empresa provienen de los procesos de pintura y recubrimiento. La compañía implementa varias estrategias de reducción que incluyen: eliminar el uso de pintura donde sea posible, cambiar a pinturas a base de agua y optimizar los procesos de pintura. Los logros notables incluyen una reducción del 69% en COV en la planta de motores de Daventry y el desarrollo de nuevos filtros de pintura en la planta de motores de Jamestown, que reducen los desechos en un 30%. La planta de motores de Darlington busca una reducción del 70% en COV mediante la conversión a pinturas a base de agua.

커민스 Inc.는 휘발성 유기 화합물(VOC) 배출량을 2023년까지 35% 감소시켜 2018년 수준에 비해 2030년까지 50% 감소하겠다는 목표를 향해 상당한 진전을 보고했습니다. 회사의 VOC 배출량의 70% 이상이 도색 및 코팅 공정에서 발생합니다. 회사는 가능한 경우 도료 사용을 줄이고, 수용성 페인트로 전환하며, 도색 공정을 최적화하는 등 다양한 감축 전략을 구현하고 있습니다. 주목할 만한 성과로는 다벤트리 엔진 공장에서 69%의 VOC 감소와 제임스타운 엔진 공장에서 폐기물을 30% 줄이는 새로운 페인트 필터 개발이 있습니다. 달링턴 엔진 공장은 수성 페인트 전환을 통해 70%의 VOC 감소를 목표로 하고 있습니다.

Cummins Inc. fait état de progrès significatifs dans la réduction des émissions de Composés Organiques Volatils (COV), avec une réduction de 35% en 2023 vers leur objectif de 50% de réduction d'ici 2030 par rapport aux niveaux de 2018. Plus de 70% des émissions de COV de l'entreprise proviennent des processus de peinture et de revêtement. L'entreprise met en œuvre diverses stratégies de réduction, notamment : l'élimination de l'utilisation de peinture lorsque cela est possible, le passage à des peintures à base d'eau et l'optimisation des processus de peinture. Parmi les réalisations notables, citons une réduction de 69% des COV à l'usine de moteurs de Daventry et le développement de nouveaux filtres à peinture à l'usine de moteurs de Jamestown, réduisant les déchets de 30%. L'usine de moteurs de Darlington vise une réduction de 70% des COV grâce à la conversion vers des peintures à base d'eau.

Cummins Inc. berichtet von erheblichen Fortschritten bei der Reduzierung der Emissionen flüchtiger organischer Verbindungen (VOC) und hat bis 2023 eine Reduzierung um 35% erreicht, mit dem Ziel, die Emissionen bis 2030 um 50% im Vergleich zu den Werten von 2018 zu senken. Über 70% der VOC-Emissionen des Unternehmens stammen aus den Lackierungs- und Beschichtungsprozessen. Das Unternehmen setzt verschiedene Reduktionsstrategien um, darunter: die Verwendung von Farbe wo möglich zu minimieren, auf wasserbasierte Farben umzusteigen und die Lackierprozesse zu optimieren. Zu den bemerkenswerten Erfolgen zählen eine Reduktion der VOC um 69% im Werk Daventry und die Entwicklung neuer Farbfilter im Werk Jamestown, die Abfälle um 30% reduzieren. Das Werk Darlington strebt eine Reduktion der VOC um 70% durch die Umstellung auf wasserbasierte Farben an.

- 35% reduction in VOC emissions achieved towards 50% 2030 target

- 69% year-over-year VOC reduction at Daventry Engine Plant

- 30% reduction in filter waste at Jamestown Engine Plant

- 10% annual paint reduction achieved through improved robot programming

- 80% reduction in service claims with new waterborne paints

- Recent acquisitions have slowed VOC reduction goal progress

Insights

This environmental initiative, while commendable, has minimal direct financial impact on Cummins' stock value. The 35% VOC reduction since 2018 and transition to waterborne paints represents incremental operational improvements rather than a significant financial catalyst. The cost savings from reduced paint usage (10% annually at JEP) and filter waste reduction (30%) are relatively minor compared to Cummins' overall operations.

The most notable business impact comes from the 80% reduction in service claims at the Daventry plant due to improved paint quality, which could marginally benefit warranty costs. However, the transition costs and ongoing implementation across facilities may offset near-term savings. While these initiatives support long-term ESG objectives and regulatory compliance, they don't materially affect current financial performance or stock valuation.

By Cummins Inc., Global Power Technology Leader

NORTHAMPTON, MA / ACCESSWIRE / November 21, 2024 / Cummins Inc.

Cummins

Volatile organic compounds (VOCs) are emitted as gases from a variety of products and processes, including paint and coating operations.

While paint can provide protection and aesthetic benefits to products, the VOCs emitted during the painting process also have environmental implications. VOCs can react with nitrogen oxide when exposed to sunlight to create ground-level ozone, contributing to smog. Painting operations also contribute to water and chemical waste and increased electricity and gas usage.

What is Cummins doing about VOC emissions?

Over

Reducing VOC emissions by eliminating the use of paint

Sometimes, the best solution is also the simplest. That's what a team of sustainability leaders and engineers from the Cummins Columbus Mid-Range Engine Plant (CMEP) discovered in 2020 when they first studied whether they could stop painting their engines.

Material science has evolved since Cummins engines began leaving CMEP over thirty years ago. What used to be made from grey iron that needed rust and corrosion-preventive coatings is now made from composites, aluminum and cast iron, which has better rust prevention capabilities. The CMEP team validated that eliminating paint from the engines would not lead to excess corrosion, ensuring the same engine performance, quality, capability and durability. By eliminating paint from these engines, the site was also able to reduce the energy, waste and water associated with the painting process.

Reducing VOC emissions by switching to waterborne paints and resins

Another effective approach to reducing VOC emissions is switching to waterborne paints. Solvent-based and waterborne paints have similar performance characteristics, but unlike traditional solvent-based paints which emit VOCs during the drying process, waterborne paints use water as the carrier for paint pigments, binders and additives. Since 2013, the Cummins Jamestown Engine Plant (JEP) in New York has used waterborne paints to comply with emissions requirements and reduce pollution.

Across the Atlantic, Cummins plants in the U.K. are also embracing waterborne paints. In 2023, Cummins' Daventry Engine Plant began to see the benefits of this transition. Not only did it reduce VOC emissions by

Reducing VOC emissions through process optimization

For sites that have already transitioned to waterborne paints, improvements continue to be made through process optimization. Process optimization focuses on improving efficiency by reducing overspray and excessive paint usage, reducing waste generation, reducing energy by optimizing pre- and post- operations.

After JEP transitioned to low-VOC waterborne paint, the plant continued seeking ways to further minimize its environmental impact. In 2023, new long-lasting paint filters were developed, reducing filter waste by approximately

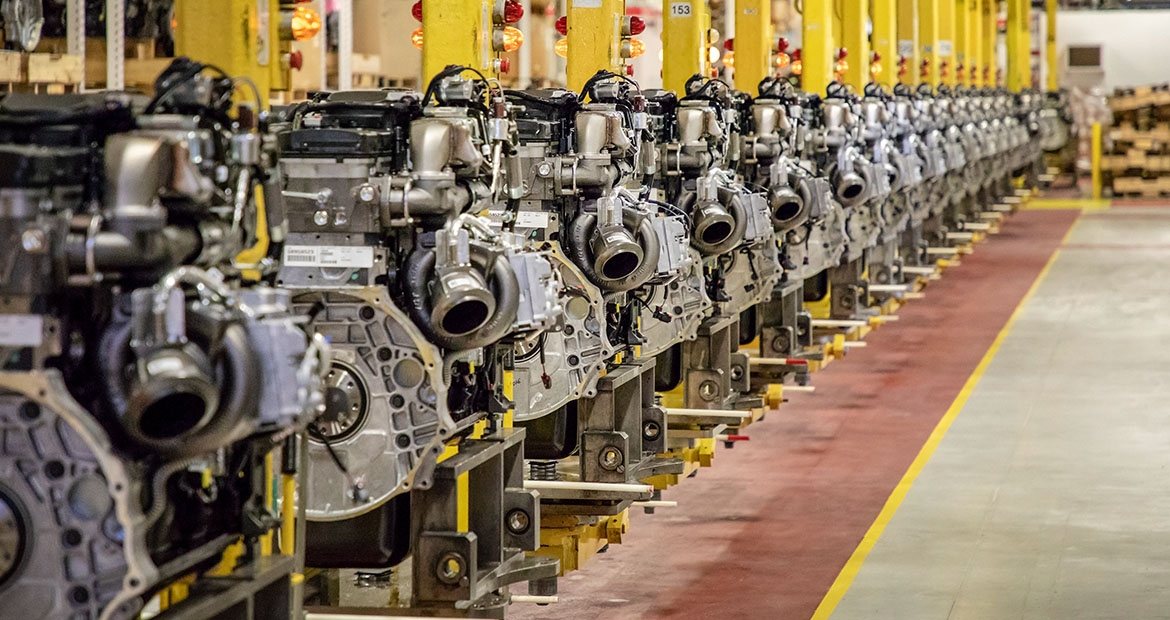

Cummins, a global power technology leader, is a corporation of complementary business segments that design, manufacture, distribute and service a broad portfolio of power solutions. The company's products range from internal combustion, electric and hybrid integrated power solutions and components including filtration, after treatment, turbochargers, fuel systems, controls systems, air handling systems, automated transmissions, electric power generation systems, microgrid controls, batteries, electrolyzers and fuel cell products.

View additional multimedia and more ESG storytelling from Cummins Inc. on 3blmedia.com.

Contact Info:

Spokesperson: Cummins Inc.

Website: https://www.3blmedia.com/profiles/cummins-inc

Email: info@3blmedia.com

SOURCE: Cummins Inc.

View the original press release on accesswire.com