New Expro Technology Estimated to Reduce Almost 150 Tons of CO2 Emissions From Rigs

Expro (NYSE: XPRO) has developed the iTONG™ system, a digital technology aimed at reducing CO2 emissions by an estimated 146 tons annually, equivalent to 58 transatlantic flights. The iTONG system automates tubular running services, saving operators nearly $2 million annually and around 50 hours of rig time per installation. This innovation not only enhances safety and efficiency but also aligns with Expro's commitment to achieving Net Zero by 2050. The technology has been successfully trialed in the North Sea, marking a significant advancement in the oil and gas sector.

- iTONG™ system reduces CO2 emissions by 146 tons annually.

- Estimated savings of nearly $2 million in rig time per installation.

- Successfully tested in 22 jobs in the North Sea, improving operational efficiency.

- None.

Insights

Analyzing...

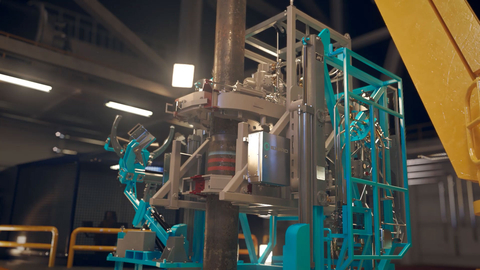

Expro's iTONG™ System - intelligent autonomous connections. (Photo: Business Wire)

While the oil and gas industry has introduced many digital innovations, tubular running services (TRS) is an area which has historically lagged. Expro, however, is driving greater rig floor automation thanks to its iTONG™ system. In addition to cutting emissions, the iTONG system is designed to help protect personnel and is estimated to save operators nearly 50 hours of rig time and

The iTONG system is the industry’s most technologically advanced single push button tubular make-up solution which allows the operator to control, execute, verify, and validate every connection make-up via a tablet or their control chair. It ensures joints of casing and tubing can be made to a specific torque, or broken out in an automated sequence, with the single push of a button.

With a reduction in the number of personnel required for tubing operations, a rig using iTONG can reduce annual emissions from rig time, travel, and accommodation by an estimated 146 tons a year – the equivalent of removing 58 10-hour flights from

Expro experts are on hand this week at Stand 2200 at ONS 2022 in Stavanger to discuss the system with conference delegates.

“Thanks to systems like iTONG, our highly skilled research and development teams are leading the industry in improving safety, reducing emissions and increasing savings across the globe. Some

“Not only does iTONG enhance the industry’s ability to improve service quality and reliability, but it is also a paradigm shift that revolutionizes the tubular running process, providing a fully autonomous solution to deliver operational excellence.”

The technology has undergone significant field trials on a high-efficiency jack-up rig in the

In a further example of the company’s commitment to driving the industry forward, iTONG is coupled with Expro’s iCAM® torque-turn tubular connection make-up system, which uses artificial intelligence to make data-driven decisions, ultimately determining whether the make-up has been successful.

Earlier this year, Expro received a Spotlight on New Technology® Award for its Autonomous Well Intervention System Galea™ at the

That partnership came as part of the company’s long-term strategy to continue to invest in transforming its business portfolio and reducing its greenhouse gas emissions, as well as its stated aim of achieving Net Zero by 2050 with a

Expro

Working for clients across the well life cycle, Expro is a leading provider of energy services, offering cost-effective, innovative solutions and what the Company considers to be best-in-class safety and service quality. The Company’s extensive portfolio of capabilities spans well construction, well flow management, subsea well access, and well intervention and integrity solutions.

With roots dating to 1938, Expro has approximately 7,200 employees and provides services and solutions to leading exploration and production companies in both onshore and offshore environments in approximately 60 countries.

Today, Expro’s wells expertise and technologies are transferable to the low carbon and renewable energy industry. As the energy industry seeks to address the challenges of tomorrow, Expro believes it is well positioned to play a leading role in enabling its clients to achieve their carbon reduction goals in support of the energy transition.

For more information, please visit: expro.com and connect with Expro on Twitter @ExproGroup and LinkedIn @Expro.

SPECIAL NOTE REGARDING FORWARD-LOOKING STATEMENTS

This press release, and oral statements made from time to time by representatives of the Company, may contain certain "forward-looking statements" within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements include statements regarding, among other things, the Company’s environmental, social and governance goals, targets and initiatives, and the benefits and success of the iTONG system, and are indicated by words or phrases such as "anticipate," "outlook," "estimate," "expect," "project," "believe," "envision," "goal," "target," "can," "will," and similar words or phrases. These forward-looking statements involve known and unknown risks, uncertainties and other factors which may cause actual results, performance or achievements to be materially different from the future results, performance or achievements expressed in or implied by such forward-looking statements. Forward-looking statements are based largely on the Company's expectations and judgments and are subject to certain risks and uncertainties, many of which are unforeseeable and beyond our control. The factors that could cause actual results, performance or achievements to materially differ include, among others the risk factors identified in the Company’s Annual Report on Form 10-K, Form 10-Q and Form 8-K reports filed with the

View source version on businesswire.com: https://www.businesswire.com/news/home/20220829005015/en/

Media Contact

MediaRelations@expro.com

Source: Expro