Manufacturers Can Now Quickly Produce High-Quality Master Patterns for Investment Casting Production with New 3D Printing Build Processor from Stratasys and Materialise

Up to

New Processor Supports Faster Time to Market for Metal Cast Parts

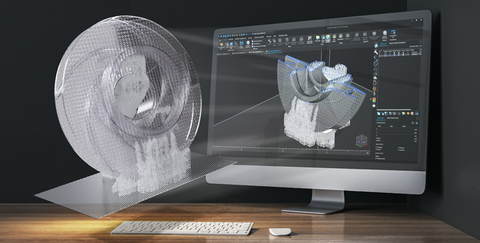

Manufacturers Can Now Quickly Produce High-Quality Master Patterns for Investment Casting Production with New 3D Printing Build Processor from Stratasys and Materialise (Photo: Business Wire)

This new build processor, developed for Stratasys Neo®450 and Neo®800 stereolithography (SLA) 3D printers, offers up to

3D printing master patterns can reduce the investment casting production time from weeks to days, potentially resulting in up to

The Stratasys Neo Build Processor for Investment Casting is particularly beneficial for manufacturers in aerospace, automotive, and industrial sectors, where speed, precision, and cost-effectiveness are paramount. Combining Somos® WaterShed® AF resin, Neo SLA technology, and advanced Materialise software with the variable layer thickness feature, produces highly accurate 3D printed master patterns requiring minimal finishing. This streamlined process is designed to yield exceptional metal castings in record time.

“This new build processor advances our mission to provide faster, more efficient solutions for producing high-quality master patterns,” said Rani Hagag, Chief Health Care and Consumer Business Officer at Stratasys. “Partnering with Materialise exemplifies how Stratasys collaborates with industry leaders to drive innovation and help our customers achieve their most challenging production goals with greater speed and precision.”

Materialise’s NxG Build Processor is a configurable software that translates large and complex 3D design files into 3D printable instructions, optimizing the 3D printing process from start to finish.

Enhanced Capabilities

Faster File Processing and Printing Speeds: Achieve quicker turnaround times with faster processing and print speeds by offloading computational tasks to the build processor, optimizing file preparation without compromising part integrity.

Improved Workflow Integration: Streamline workflows and reduce the learning curve for new users with a processor that integrates seamlessly with Materialise’s Lattice module and Stratasys’s Titanium™ software for Neo systems, minimizing human error.

Superior Part Quality: Enhance surface finish and reduce post-processing time with advanced variable layer thickness options that produce stable, high-quality master patterns.

Customizable Build Parameters: Optimize production with customizable parameters for geometry, supports, and lattices, leading to faster scanning and improved overall productivity.

“Our collaboration with Stratasys focuses on creating seamless integrations between software and hardware to make AM adoption more effortless for our customers,” said Udo Eberlein, Vice President Materialise Software. “With the NxG Build Processor for Stratasys Neo printers, we enable a broad set of applications but also unlock new possibilities for niche applications like investment casting, where the flexibility of additive manufacturing meets the reliability of metal casting processes that have been refined over thousands of years. This collaboration helps improve processing speed and print productivity, but is about more than just advancing technology; it’s about empowering industries to push the boundaries of what they can achieve with AM.”

About Stratasys

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, X/Twitter, LinkedIn, or Facebook. Stratasys reserves the right to utilize any of the foregoing social media platforms, including Stratasys’ websites, to share material, non-public information pursuant to the SEC’s Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

About Materialise

Materialise incorporates more than three decades of 3D printing experience into a range of software solutions and 3D printing services that empower sustainable 3D printing applications. Our open, secure and flexible end-to-end solutions enable industrial manufacturing and mass personalization in various industries — including healthcare, automotive, aerospace, eyewear, art and design, wearables and consumer goods. Headquartered in

View source version on businesswire.com: https://www.businesswire.com/news/home/20240909375286/en/

Stratasys Media and Investor Contacts:

Media:

Chris Reese, Stratasys Corporate,

Erik Snider, Stratasys Corporate, Global, EMEA Region and Israel Public Relations, +972 74 745 6053

Investor Relations:

Yonah Lloyd, Stratasys Investor Relations, +972 74 745 4919

Materialise Press Contact

Kristof Sehmke, email: kristof.sehmke@materialise.be

Source: Stratasys