SLB achieves breakthrough results in sustainable lithium production

-

Nevada demonstration plant integrates direct lithium extraction (DLE), concentration and conversion technologies to sustainably produce lithium at scale - Integrated technology solution produces lithium from brine 500 times faster than conventional methods while using significantly less land, water and chemical reagents

-

Verified results confirm recovery rate of

96% lithium from brine at operational rates

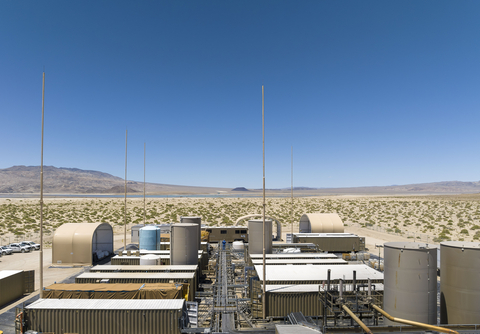

SLB's demonstration plant in Clayton Valley proves its unique integrated approach to produce scalable quantities of lithium in the fastest, most economical and sustainable way for today’s market. (Photo: Business Wire)

The proprietary integrated solution combines SLB’s subsurface expertise with surface engineering of advanced technologies that include direct lithium extraction (DLE). It produces lithium 500 times faster than conventional methods while using only 10 percent of the land. Operating at approximately one tenth the size of a commercial-scale facility, the plant reached a verified recovery rate1 of

SLB’s integrated solution is a complete, end-to-end process that includes advanced impurity treatment and concentration technologies to produce high-purity lithium carbonate or hydroxide. The solution also uses significantly less water, energy and fewer chemical reagents in comparison to other DLE-based offerings.

“Lithium is a key enabler of electrification, so we must find ways to accelerate its production without adversely affecting the environment,” said Gavin Rennick, president of SLB’s New Energy business. “SLB’s demonstration plant in Clayton Valley proves our unique integrated approach to produce scalable quantities of lithium in the fastest, most economical and sustainable way for today’s market. This accelerates deployment of viable commercial-scale facilities for high-quality lithium products that are the backbone of our electrification economy.”

The conventional alternative for producing lithium from brine at scale is evaporation. This process not only requires a significant amount of land but also results in massive water loss. Salt, underground minerals and used chemicals are then left at the surface, creating impact on biodiversity and the environment. SLB’s sustainable lithium production solution enhances sustainability by reducing water use. The proprietary process also returns the spent brine, or the brine with a reduced lithium concentration, back to its source after the lithium is processed and separated.

The entire SLB solution, from extracting lithium from brine to converting it to technical-grade lithium carbonate, takes just hours. By comparison, evaporation methods can take up to 18 months and have a much lower recovery rate of 50 percent or less.

Lithium is sold commercially as lithium chloride, used as a feedstock for producing lithium metal; lithium carbonate, used in smartphones and short-range EVs; and lithium hydroxide, used in long-range EV batteries. SLB’s solution is highly flexible and can be adjusted to produce any of these products.

In proving this solution at its pilot plant, SLB completed specific technical milestones allowing it to fully qualify under the earn-in agreement with Pure Energy Minerals Ltd. and, at its option, may acquire

1. Recovery rate independently verified by WETLAB-Western Environmental Testing Laboratory of |

About SLB

SLB (NYSE: SLB) is a global technology company that drives energy innovation for a balanced planet. With a global footprint in more than 100 countries and employees representing almost twice as many nationalities, we work each day on innovating oil and gas, delivering digital at scale, decarbonizing industries, and developing and scaling new energy systems that accelerate the energy transition. Find out more at slb.com.

Cautionary Statement Regarding Forward-Looking Statements:

This press release contains “forward-looking statements” within the meaning of the

View source version on businesswire.com: https://www.businesswire.com/news/home/20240909767336/en/

Media

Moira Duff – Director of External Communications

SLB

Tel: +1 (713) 375-3407

media@slb.com

Investors

James R. McDonald – SVP of Investor Relations & Industry Affairs

Joy V. Domingo – Director of Investor Relations

SLB

Tel: +1 (713) 375-3535

investor-relations@slb.com

Source: SLB