Québec Nickel Initiates Metallurgical Test Program at Fortin Sill Zone

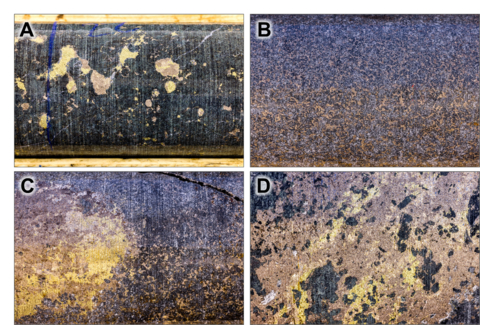

Figure 1. Select photographs of some of the metallurgical test work program drill core provided to SGS Canada. A – blebby sulphide mineralization from hole QDG-23-29M at 22.00 metres depth (HQ core, long dimension of photograph is 8 cm); B – net texture sulphides from hole QDG-23-29M at 36.45 metres depth (HQ core, long dimension of photograph is approximately 6.0 cm); C – disseminated and semi massive sulphides from hole QDG-23-29M at 36.60 metres (HQ core, long dimension of photograph is approximately 6.0 cm); and D – semi massive sulphide vein from hole QDG-23-28M at 41.25 metres hole depth (HQ core, long dimension of photograph is approximately 6.0 cm). (Photo: Business Wire)

The metallurgical study has been initiated to follow-up on significant drilling results returned from the Company’s 2022 exploration program at Fortin Sill Zone including 31.00 metres of

Metallurgical Drilling and Sampling

In April 2023, the Company completed several HQ diameter drill holes at the Fortin Sill Zone which will supply fresh material for the metallurgical test work program. The dedicated metallurgical holes were designed to mimic previously completed holes at Fortin Sill Zone and targeted three distinct styles and grades of mineralization including:

-

Low grade disseminated and blebby sulphide mineralization with a target average grade of

0.30% nickel + copper -

Moderate grade blebby to heavily disseminated mineralization with a target average grade

0.75% nickel + copper -

High-grade net texture to semi-massive mineralization with a target grade of greater than

1.50% nickel + copper

A total of 150 kilograms of mineralized HQ diameter drill core has been collected for the study and comprises three 50-kilogram samples of each of the styles and target grades of mineralization. Select pieces of representative whole core were selected, catalogued, and packaged in secured plastic pails before being delivered to SGS’

Metallurgical Test Work Program

SGS has been contracted to complete a scoping level metallurgical test work program to evaluate the amenability of the Fortin Sill Zone to produce a saleable Critical Metals (Ni-Cu-Co-PGE+Au) concentrate(s). The scope of SGS’ work program includes:

- Bond ball mill grindability testing

- Floatation test work

- Solid-liquid separation testing and

- Environmental analyses

As part of the work program, the study will also evaluate if efficiencies and/or recoveries can be optimized by producing a combined nickel-copper concentrate or two separate nickel and copper concentrates. The work will also evaluate how the other metals of interest, for example cobalt, platinum, palladium, and gold will behave under different recovery scenarios. The flowsheet comparison will be performed on a blend of the three samples representing low, moderate, and high-grade Ni-Cu-Co-PGE-Au mineralization, culminating in a locked cycle test on the blended composite and batch rougher and cleaner tests and locked cycle tests on the grade variability samples using the best performing flowsheet.

The 150 kilograms of core samples arrived at the SGS facility at the end of April and preliminary work has begun. The work program is estimated to be completed in Q4 2023.

Core Processing & QAQC

Québec Nickel has implemented a quality assurance and quality control (“QAQC”) program for its drilling programs to ensure best practices for logging, sampling, and analysis of its drill core as well as for the collection and analyses of rock samples. This includes the regular insertion of geochemical blanks, duplicates and multiple Ni-Cu-PGE-Au certified reference material standards (CRMs) into the sample stream.

Drill core is collected by Ducros Project personnel daily from the drill rigs and transported in secured core boxes to QNI’s core logging facilities in

Core destined for geochemical analyses is identified and labeled by core logging geologists and subsequently sawed in half by a diamond blade. One half of the NQ-diameter core sample is placed in a labeled and secured sample bag. The remaining half of the core sample is returned to its core box for archiving. All core samples are transported from QNI’s logging facilities to either AGAT Laboratories’ sample preparation facility or SGS’ sample preparation facility, both located in Val-d’Or,

AGAT Laboratories and SGS Natural Resources operate under a Quality Management System that complies with the ISO/IEC 17025:2017 standard. Analysis for precious metals (gold, platinum, and palladium) is completed by Fire Assay with an ICP-OES finish while analyses for nickel, copper and 41 other elements are performed using AGAT’s 4 Acid Digest – Metals Package, with an ICP-OES finish.

QUALIFIED PERSON

Gary DeSchutter, M.Sc., P.Geo., Vice-President of Exploration for Québec Nickel Corp., and a Qualified Person (“QP”) as defined under National Instrument 43-101 (“NI 43-101”), has reviewed, and approved the scientific and technical content of this press release.

ABOUT QUEBEC NICKEL CORP.

Québec Nickel Corp. is a mineral exploration company focused on acquiring, exploring, and developing critical metals (Ni-Cu-Co-PGE) projects in

The CSE has neither approved nor disapproved the contents of this news release. Neither the CSE nor its Market Regulator (as that term is defined in the policies of the CSE) accepts responsibility for the adequacy or accuracy of this release.

CAUTIONARY AND FORWARD-LOOKING STATEMENTS

This news release includes certain statements that may be deemed “forward-looking statements”. All statements in this news release, other than statements of historical facts that address events or developments that the Company expects to occur, are forward-looking statements. Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words “expects,” “plans,” “anticipates,” “believes,” “intends,” “estimates,” “projects,” “potential” and similar expressions, or that events or conditions “will,” “would,” “may,” “could” or “should” occur. Although the Company believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance, and actual results may differ materially from those in the forward-looking statements. Factors that could cause the results to differ materially from those in forward-looking statements include market prices, continued availability of capital and financing, and general economic, market, or business conditions. Investors are cautioned that such statements are not guarantees of future performance and that actual results or developments may differ materially from those projected in the forward-looking statements. Forward-looking statements are based on the beliefs, estimates, and opinions of the Company's management on the date the statements are made. Except as required by applicable securities laws, the Company undertakes no obligation to update these forward-looking statements if management's beliefs, estimates, opinions, or other factors should change.

View source version on businesswire.com: https://www.businesswire.com/news/home/20230510005421/en/

On behalf of the Board of Directors

Richard Dufresne

Chief Executive Officer and Director

1 (855) 764-2535 (QNICKEL)

info@quebecnickel.com

Source: Québec Nickel Corp.