PPG launches portfolio of energy-curable coatings for coiled metal

PPG DURANEXT products cure in seconds at ambient temperatures for faster finishing and energy savings

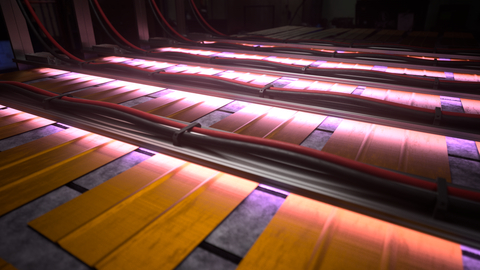

PPG DuraNEXT coatings use an electron beam or ultra-violet energy to convert a liquid coating into a fully cured solid finish in seconds, without any significant loss of thickness or weight. (Photo: Business Wire)

Unlike traditional coil coating systems that require very high temperatures to drive the curing process, PPG DuraNEXT coatings use an electron beam or ultra-violet energy to convert a liquid coating into a fully cured solid finish in seconds, without any significant loss of thickness or weight.

“As an early pioneer of energy-curable coatings for wood, PPG leveraged 30 years of expertise to develop these state-of-the-art technologies for interior and exterior metal building product applications,” said Irene Tasi, PPG senior vice president, Industrial Coatings. “Developing UV-and EB-curable coatings for pre-painted metal is a remarkable advancement in energy curing technologies and illustrates PPG’s commitment to innovation and more sustainable manufacturing across the industries that we serve.”

PPG DuraNEXT solutions are engineered for lasting durability and offer:

- Reduced energy usage, water consumption and CO2 emissions, compared to traditional thermal cure coatings.

- Formulations made without solvents that release volatile organic compounds (VOCs).

- Faster finishing with curing in less than one second without using heat.

- Application with multiple methods, including roll-, curtain- and slot-die-coating

- Solutions that can be customized to meet most requirements for weatherability, durability, chemical resistance and flexibility.

PPG explored the history, benefits and evolutionary advancements in UV and EB technologies, in a technical paper that was published in March.

“There is no doubt that coil coaters will adopt these technologies with greater frequency due to their advantages, most notably significant energy savings and fast curing,” said Craig Smith, PPG global technical platform director, Coil Coatings, and one of the lead authors of the technical paper.

The PPG DuraNEXT portfolio includes:

- Backers available in both UV and EB formulations to accommodate various application equipment setups. These can be applied over a primer or used as a direct-to-metal application.

- Primers available in UV-curable formulations. UV primer can be used under an EB topcoat or with a conventional thermal cure topcoat. These primers could also be used in conjunction with a wet-on-wet applied topcoat and cured with EB in a single pass.

- Basecoats available in a full range of glosses and colors for both interior and exterior applications and with options that include smooth, textured and wrinkled finishes. These can also be formulated as a one-coat direct-to-metal solution.

- Clearcoats engineered to preserve digitally printed inks with a protective layer that adds weatherability and scratch- and abrasion-resistance for residential and commercial applications.

“Our portfolio of EB and UV coil coatings will grow as we continue to develop new energy curable solutions that meet the changing needs of our customers,” Smith said.

For more information on the full PPG DuraNEXT product portfolio, visit PPG DURANEXTTM | PPG Industrial Coatings.

PPG: WE PROTECT AND BEAUTIFY THE WORLD®

At PPG (NYSE:PPG), we work every day to develop and deliver the paints, coatings and specialty materials that our customers have trusted for 140 years. Through dedication and creativity, we solve our customers’ biggest challenges, collaborating closely to find the right path forward. With headquarters in

PPG DuraNEXT, the PPG Logo and We protect and beautify the world are registered trademarks of PPG Industries Ohio, Inc.

CATEGORY Industrial Coatings

View source version on businesswire.com: https://www.businesswire.com/news/home/20240730724436/en/

Alicia Cafardi

+1 412 510 1907

acafardi@ppg.com

www.ppgindustrialcoatings.com

Source: PPG