Amplify Cell Technologies Begins Construction of Mississippi Battery Cell Factory

Amplify Cell Technologies, a joint venture of Accelera, Daimler Trucks & Buses US Holding, and PACCAR, has started constructing a battery cell manufacturing facility in Marshall County, Mississippi.

The 500-acre site will host a 2 million sq. ft. facility with an annual production capacity of 21 GWh of lithium-iron-phosphate (LFP) battery cells. The plant aims to begin production in 2027, creating over 2,000 manufacturing jobs.

This project represents the largest payroll commitment in Mississippi's history. Partners have committed $2-3 billion to this venture. EVE Energy, a 10% stakeholder, will provide technology expertise.

The facility will help localize the battery supply chain, important for the electric commercial vehicle market in North America, and support the transition to zero-emission technologies.

- Construction of a 2 million sq. ft. battery manufacturing plant with 21 GWh annual capacity.

- Creation of over 2,000 U.S. manufacturing jobs.

- Largest payroll commitment in Mississippi's history.

- Partners committed $2-3 billion investment.

- Localization of the battery supply chain for North America.

- None.

Insights

Amplify Cell Technologies breaking ground on a new battery cell manufacturing plant in Marshall County, Mississippi represents a significant capital investment in the electric vehicle (EV) sector. The plant aims to produce 21-gigawatt hours (GWh) of lithium-iron-phosphate (LFP) battery cells annually, marking a substantial capacity addition to the market.

From a financial perspective, this joint venture between Accelera, Daimler Trucks & Buses US Holding LLC and PACCAR, with investments ranging between

The choice of LFP battery technology, known for its cost-effectiveness and durability, implies a strategic move to offer competitive and reliable products in the commercial transportation sector. This could drive higher margins due to lower production costs and greater appeal to a price-sensitive market segment.

For investors, this initiative enhances confidence as it integrates vertical supply chain localization, reducing dependency on international suppliers and potentially mitigating risks associated with global supply chain disruptions. However, the long-term returns will depend on the successful ramp-up of production and achieving the targeted efficiencies.

This project supports the transition to zero-emissions technologies as part of a broader ESG (Environmental, Social, Governance) strategy, which is increasingly influential in investment decisions.

The establishment of this large-scale battery cell manufacturing facility in Mississippi is a strategic move that significantly bolsters the North American EV industry's infrastructure. The choice of lithium-iron-phosphate (LFP) battery cells is particularly noteworthy. LFP batteries are prized for their longevity, thermal stability and enhanced safety compared to alternative chemistries. Additionally, they are less reliant on cobalt, a mineral with controversial sourcing and sustainability issues.

This initiative aligns with the industry's push towards decarbonizing commercial transport, which is critical for meeting targets set by the Paris Climate Agreement. By localizing production, the project also aims to create a resilient supply chain for EV manufacturers, reducing lead times and potentially lowering costs associated with logistics and tariffs.

However, critical challenges lie ahead. The industry's rapid technological advancements require continuous R&D investment to stay competitive. Moreover, the operational efficiency and cost-effectiveness of this new plant will be important in determining its market impact. Collaborating with EVE Energy, a leader in battery technology, is a positive indicator of the project's potential success.

This new facility in Mississippi is poised to influence the commercial transportation market significantly. By adding 21-GWh of production capacity, it addresses the growing demand for commercial EVs, particularly from logistics and freight services seeking sustainable solutions. This capacity boost is critical as market forecasts predict an exponential increase in demand for EV batteries over the next decade.

The creation of over 2,000 jobs is a substantial economic boost for the region, likely fostering local economic growth and enhancing community support for the facility. Additionally, the joint venture's strong commitment to the project, backed by substantial investment, signals a long-term vision and stability, which is attractive to investors looking for sustained growth opportunities in the green technology sector.

From a market perspective, Amplify's focus on producing durable and cost-effective LFP batteries may give it a competitive advantage, especially in the commercial sector where cost and reliability are paramount. However, market penetration and scalability will depend on the facility's ability to meet production timelines and quality standards consistently.

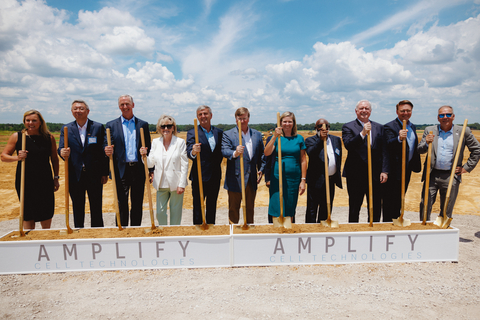

Amplify Cell Technologies Board Members and Distinguished Guests Break Ground (Photo: Business Wire)

The 500-acre site will be home to a two million square-foot, energy efficient facility with an annual manufacturing capacity of 21-gigawatt hours (GWh) for the production of lithium-iron-phosphate (LFP) battery cells. Amplify plans to begin battery cell production in 2027 and is expected to create more than 2,000

“I am thrilled to be here with so many of our partners to break ground on this new battery cell manufacturing facility in Marshall County,” said Kel Kearns, CEO of Amplify Cell Technologies. “United in the mission to decarbonize our highways and interstates, our founding partners are making a serious commitment. Marking the start of construction on site signifies this collective effort, and together we will lead the transformation of the commercial transportation industry.”

Leaders from Accelera, Daimler and PACCAR were joined by

“Mississippi is incredibly excited to welcome this historic private sector investment from the new joint venture between Accelera, Daimler Truck, and PACCAR,” Governor Tate Reeves said. “This project is the largest payroll commitment in state history, and it will bring an incredible 2,000 new jobs to this community. This fantastic investment from these industry leaders will help to further charge Mississippi’s electric economy.”

“As the transportation industry evolves and energy demands grow, it’s crucial that we have American facilities producing the materials and technologies necessary to meet those needs. This joint venture is not only a major job booster for

“This project will change thousands of lives in North Mississippi,” Senator Roger Wicker added. “Major development decisions are never made lightly, but

The new facility will produce LFP battery cells, a cell chemistry chosen for its durability and cost-effectiveness. This initiative will localize the battery supply chain, making it more robust and responsive to the needs of the growing electric commercial vehicle market in

Accelera, Daimler Truck and PACCAR have committed a combined

About Amplify Cell Technologies

Amplify Cell Technologies, a joint venture between Accelera, Daimler Trucks & Buses US Holding LLC, and PACCAR with EVE Energy as technology partner, is localizing battery cell production and the battery supply chain in

Located in

For more information about Amplify Cell Technologies, visit amplifycelltech.com.

About Accelera

Accelera provides a diverse portfolio of zero-emissions solutions for the world’s most economically vital industries, empowering them to accelerate the transition to a sustainable future. Accelera, a business segment of Cummins Inc., is both a components supplier and integrator, focused on batteries, hydrogen fuel cells, e-axles, traction motors and inverters, integrated powertrain solutions, and electrolyzers. Accelera currently has operations in

Cummins, a global power solutions leader, is a corporation of complementary business segments that design, manufacture, distribute and service a broad portfolio of power solutions. Headquartered in

To learn more about Accelera, visit accelerazero.com.

About Daimler Truck

Daimler Truck Holding AG ("Daimler Truck") is one of the world's largest commercial vehicle manufacturers with more than 40 main locations and more than 100,000 employees worldwide. The business activities of Daimler Truck are divided into five reporting segments: Trucks North America (TN) with the truck brands Freightliner and Western Star and the school bus brand Thomas Built Buses, Trucks Asia (TA) with the commercial vehicle brands FUSO, BharatBenz and RIZON, Mercedes-Benz (MB) with the truck brand of the same name, and Daimler Buses (DB) with the bus brands Mercedes-Benz and Setra. The fifth segment is Daimler Truck Financial Services (DTFS). In addition to the sale of new and used commercial vehicles, the company also offers aftersales services and connectivity solutions and invests in advanced technologies such as zero emissions, hydrogen, charging infrastructure and autonomous driving.

About PACCAR

PACCAR is a global technology leader in the design, manufacture and customer support of high-quality light-, medium- and heavy-duty trucks under the Kenworth, Peterbilt and DAF nameplates. PACCAR vehicles combine state-of-the-art diesel and zero-emissions powertrains with comprehensive PACCAR charging solutions and infrastructure support. PACCAR also provides financial services and information technology, and distributes truck parts related to its principal business.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240701093920/en/

Cummins Media Contact:

Jon Mills

+1-317-658-4540

jon.mills@cummins.com

Daimler Truck Media Contact:

Andrew Johnson

+1-503-799-7234

andrew.johnson@daimlertruck.com

PACCAR Media Contact:

Ken Hastings

+1-425-468-7530

ken.hastings@paccar.com

Source: PACCAR