LightPath Completes Qualification of Its Mantis(TM) Camera in $500 Million Global Furnace Monitoring Market

LightPath Technologies has completed the development and qualification of its new Mantis™ camera, designed for high-temperature monitoring in boilers and furnaces within power plants. This camera offers enhanced accuracy and reliability compared to existing Pyrometers, covering a broader range of temperatures without the need for expensive cryogenic cooling devices. Tested in South Carolina, the Mantis camera specifically caters to applications in Utility & Recovery Boilers and Kilns, providing significant safety and efficiency benefits. With the global furnace monitoring market estimated at over $500 million annually, LightPath's innovation positions it to capture a notable share of this growing sector. The market is expected to expand due to the G7's initiative to restrict fossil fuel electric generation by 2035, pushing for new power plant constructions and conversions of old coal plants.

- Completion and qualification of the Mantis camera.

- Enhanced accuracy and reliability for high-temperature monitoring.

- Broader temperature range without expensive cryogenic cooling.

- Significant cost reduction in per-camera expenses.

- Potential to tap into a $500 million global market.

- Growth potential due to G7’s fossil fuel restrictions.

- Field testing in South Carolina confirming camera’s capabilities.

- None reported in the PR.

Insights

The recent qualification of LightPath's Mantis™ camera marks a significant advancement in furnace monitoring technology. Traditional pyrometers and cameras are limited by their temperature range and often require expensive cooling devices to function in extreme conditions. LightPath's camera, however, operates effectively without the need for such cooling devices, making it potentially more cost-effective and easier to maintain.

The innovation lies in its ability to monitor a broad range of temperatures, which is important in industries like power generation and steel production. This technology not only enhances the accuracy and reliability of temperature monitoring but also improves overall process safety. By providing detailed thermal imaging, the Mantis camera can help in early detection of faults or inefficiencies, leading to better preventative maintenance and reduced downtime.

In terms of impact, this could result in significant cost savings and increased operational efficiency for industries that adopt this technology. Additionally, the camera's design for specific applications indicates a tailored approach that meets the varied needs of different industrial processes.

The global furnace monitoring market, valued at over

Moreover, the timing of this innovation coincides with a significant shift in the global energy landscape. The G7's decision to restrict fossil fuel-based electric generation facilities by 2035 underscores the growing demand for advanced monitoring technologies in new and converted power plants. LightPath's camera could be pivotal in facilitating this transition, offering enhanced monitoring capabilities in a cost-effective manner.

In the short term, LightPath may see a boost in sales as industries begin to adopt this new technology. Long-term benefits could include sustained market presence and increased brand recognition as a leader in optical and infrared technologies.

From a financial perspective, the successful qualification of the Mantis™ camera signals potential revenue growth for LightPath. The company's ability to innovate and expand its product offerings into new markets is a positive indicator of its strategic direction and operational capabilities. By tapping into the $500 million global furnace monitoring market, LightPath stands to gain a significant share, which could positively impact its earnings and stock performance.

Additionally, the reduced dependence on expensive cooling devices not only makes the camera more attractive to potential customers but also suggests lower production costs, which can enhance profit margins. Investors should monitor upcoming sales figures and any further product developments that might solidify LightPath’s market position.

However, it's also important to consider any potential competition. While LightPath's technology appears advanced, other companies might develop similar solutions, impacting LightPath's market share and pricing power. Despite this, the current trajectory looks promising, with both short-term and long-term growth potential.

LightPath's Mantis Camera to Provide Accurate and Reliable Monitoring of Boilers and Furnaces in Power Plants

ORLANDO, FL / ACCESSWIRE / May 15, 2024 / LightPath Technologies, Inc. (NASDAQ:LPTH) ("LightPath," the "Company," or "we"), a leading vertically integrated global manufacturer and integrator of proprietary optical and infrared technologies, has completed development and received qualification of a new version of its Mantis™ camera, specifically designed for monitoring high-temperature processes inside boilers and furnaces in power plants.

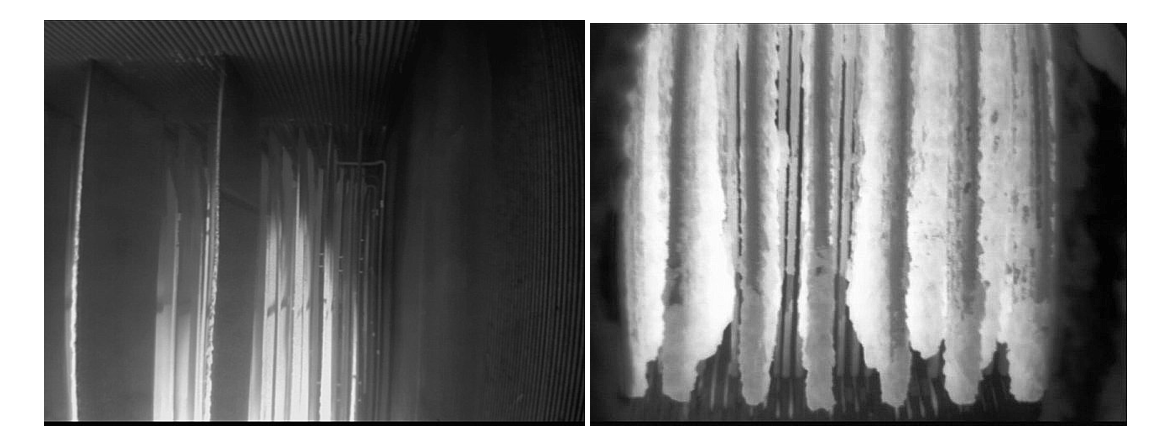

Industrial and power plant settings, with their extremely high and low-temperature processes, currently rely on using Pyrometers or cameras that can only image a small range of temperatures to monitor progress and process safety. However, LightPath's new camera, which was tested and qualified at customer sites that utilize central Appalachian Coal and Biomass in South Carolina, offers a superior solution. The Mantis camera provides more accurate and reliable monitoring of extreme-temperature processes across a much larger range of temperatures than current technology, including Utility & Recovery Boilers, Furnaces, and Kilns, enhancing process safety and efficiency for our customers.

LightPath announced the first version of its Broadband uncooled Mantis™ camera in December 2022, followed by additional versions designed for long-range detection and other specific customer applications. The Mantis camera enables thermal imaging to view the key mid wavelength without an expensive cryogenic cooling device like other cameras, significantly reducing per-camera expense. The field qualification of a new version of the camera signifies the considerable value in the innovation of developing an uncooled camera operating in the mid-wave and allows LightPath to tap into a new market, as well as expand its existing business in that market.

The global market for furnace monitoring cameras is estimated to be over

About LightPath Technologies

LightPath Technologies, Inc. (NASDAQ: LPTH) is a leading global, vertically integrated provider of optics, photonics and infrared solutions for the industrial, commercial, defense, telecommunications, and medical industries. LightPath designs and manufactures proprietary optical and infrared components including molded glass aspheric lenses and assemblies, custom molded glass freeform lenses, infrared lenses and thermal imaging assemblies, fused fiber collimators, and proprietary Black Diamond™ ("BD6") chalcogenide-based glass lenses. LightPath also offers custom optical assemblies, including full engineering design support. The Company is headquartered in Orlando, Florida, with manufacturing and sales offices in Dallas Texas, Latvia and China.

LightPath's wholly-owned subsidiary, Visimid Technologies, was acquired in July 2023, and specializes in the design and development of customized infrared cameras, for the industrial and defense industries. Such customized cameras are often sold together with customized optical assemblies from LightPath.

LightPath's wholly-owned subsidiary, ISP Optics Corporation, manufactures a full range of infrared products from high-performance MWIR and LWIR lenses and lens assemblies. ISP's infrared lens assembly product line includes athermal lens systems used in cooled and un-cooled thermal imaging cameras. Manufacturing is performed in-house to provide precision optical components including spherical, aspherical and diffractive coated infrared lenses.

For more information on LightPath and its businesses, please visit www.lightpath.com.

Forward-Looking Statements

This press release includes statements that constitute forward-looking statements made pursuant to the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. Forward-looking statements may be identified by the use of words such as "forecast," "guidance," "plan," "estimate," "will," "would," "project," "maintain," "intend," "expect," "anticipate," "prospect," "strategy," "future," "likely," "may," "should," "believe," "continue," "opportunity," "potential," and other similar expressions that predict or indicate future events or trends or that are not statements of historical matters. These forward-looking statements are based on information available at the time the statements are made and/or management's good faith belief as of that time with respect to future events and are subject to risks and uncertainties that could cause actual results to differ materially from those expressed in or suggested by the forward-looking statements. Factors that could cause or contribute to such differences include, but are not limited to, the impact of varying demand for the Company products; the ability of the Company to obtain needed raw materials and components from its suppliers; actions governments, businesses, and individuals take in response to the pandemic, including restrictions on onsite commercial interactions; general economic uncertainty in key global markets and a worsening of global economic conditions or low levels of economic growth; geopolitical tensions, the Russian-Ukraine conflict, and the Hamas/Israel war; the effects of steps that the Company could take to reduce operating costs; the inability of the Company to sustain profitable sales growth, convert inventory to cash, or reduce its costs to maintain competitive prices for its products; circumstances or developments that may make the Company unable to implement or realize the anticipated benefits, or that may increase the costs, of its current and planned business initiatives; and those factors detailed by LightPath Technologies, Inc. in its public filings with the Securities and Exchange Commission, including its Annual Report on Form 10-K and Quarterly Reports on 10-Q. Should one or more of these risks, uncertainties, or facts materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those indicated or anticipated by the forward-looking statements contained herein. Accordingly, you are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date they are made. Forward-looking statements should not be read as a guarantee of future performance or results and will not necessarily be accurate indications of the times at, or by, which such performance or results will be achieved. Except as required under the federal securities laws and the rules and regulations of the Securities and Exchange Commission, we do not have any intention or obligation to update publicly any forward-looking statements, whether as a result of new information, future events, or otherwise.

Sales Contact:

Jason Messerschmidt

VP Global Sales & Marketing

jmesserschmidt@lightpath.com

+570 449 5555

Contact:

Brian M. Prenoveau, CFA

MZ Group - MZ North America

LPTH@mzgroup.us

+561 489 5315

SOURCE: LightPath Technologies, Inc.

View the original press release on accesswire.com