LIFT reports laboratory metallurgical recoveries averaging 79% producing a high-quality spodumene concentrate grading 5.83% Li2O at the Yellowknife Lithium Project

Li-FT Power (TSXV: LIFT) (OTCQX: LIFFF) reports positive results from metallurgical testing on eight spodumene deposits at its Yellowknife Lithium Project in Northwest Territories, Canada. The tests, conducted by SGS Canada Inc., included heavy liquid separation, dense media separation (DMS), and batch flotation.

Key findings:

- Average spodumene concentrate grade: 5.83% Li2O

- Average global lithium recovery: 79.1%

- Two-stage DMS + flotation flowsheet: 81-89% lithium recovery

- Single-stage DMS + flotation flowsheet: 61-72% lithium recovery

CEO Francis MacDonald highlighted that the results, particularly the pilot-scale DMS testing, support the high-value potential of the Yellowknife lithium project for early mining sites and long-term production.

Li-FT Power (TSXV: LIFT) (OTCQX: LIFFF) riporta risultati positivi dai test metallurgici su otto giacimenti di spodumene presso il suo progetto di litio di Yellowknife nei Territori del Nord-Ovest, Canada. I test, condotti da SGS Canada Inc., hanno incluso separazione in liquido pesante, separazione in media densa (DMS) e flottazione in batch.

Risultati chiave:

- Grado medio del concentrato di spodumene: 5.83% Li2O

- Recupero globale medio di litio: 79.1%

- Flusso di lavoro DMS + flottazione a due stadi: recupero di litio dell'81-89%

- Flusso di lavoro DMS + flottazione a singolo stadio: recupero di litio del 61-72%

Il CEO Francis MacDonald ha sottolineato che i risultati, in particolare i test DMS su scala pilota, supportano l'alto potenziale di valore del progetto di litio di Yellowknife per i siti minerari precoci e la produzione a lungo termine.

Li-FT Power (TSXV: LIFT) (OTCQX: LIFFF) informa sobre resultados positivos de pruebas metalúrgicas en ocho depósitos de espodumena en su Proyecto de Litio Yellowknife en los Territorios del Noroeste, Canadá. Las pruebas, realizadas por SGS Canada Inc., incluyeron separación por líquido pesado, separación por medios densos (DMS) y flotación por lotes.

Hallazgos clave:

- Grado promedio del concentrado de espodumena: 5.83% Li2O

- Recuperación global promedio de litio: 79.1%

- Flujo de trabajo DMS + flotación en dos etapas: recuperación de litio del 81-89%

- Flujo de trabajo DMS + flotación en una sola etapa: recuperación de litio del 61-72%

El CEO Francis MacDonald destacó que los resultados, en particular las pruebas DMS a escala piloto, apoyan el alto potencial de valor del proyecto de litio de Yellowknife para sitios de minería temprana y producción a largo plazo.

Li-FT Power (TSXV: LIFT) (OTCQX: LIFFF)는 캐나다 노스웨스트 준주의 옐로우나이프 리튬 프로젝트에서 8개의 스포듐니 지층에 대한 메탈루르기 테스트에서 긍정적인 결과를 보고했습니다. SGS Canada Inc.에서 수행한 테스트에는 중액 분리, 밀도가 높은 매체 분리(DMS) 및 배치 플로타이션이 포함되었습니다.

주요 발견:

- 스포듐니 농축물 평균 등급: 5.83% Li2O

- 전 세계 리튬 회수 평균: 79.1%

- 2단계 DMS + 플로타이션 흐름도: 리튬 회수 81-89%

- 1단계 DMS + 플로타이션 흐름도: 리튬 회수 61-72%

CEO 프랜시스 맥도날드는 특히 파일럿 규모 DMS 테스트 결과가 조기 채굴 사이트와 장기 생산을 위한 옐로우나이프 리튬 프로젝트의 높은 가치 잠재력을 지지한다고 강조했습니다.

Li-FT Power (TSXV: LIFT) (OTCQX: LIFFF) annonce des résultats positifs provenant des tests métallurgiques réalisés sur huit dépôts de spodumène à son projet de lithium de Yellowknife dans les Territoires du Nord-Ouest, Canada. Les tests, effectués par SGS Canada Inc., comprenaient une séparation par liquide lourd, une séparation par milieux denses (DMS) et une flottation par lots.

Principales conclusions :

- Grade moyen du concentré de spodumène : 5.83% Li2O

- Récupération moyenne globale de lithium : 79.1%

- Flux de traitement DMS + flottation en deux phases : récupération de lithium de 81 à 89%

- Flux de traitement DMS + flottation en une seule phase : récupération de lithium de 61 à 72%

Le PDG Francis MacDonald a souligné que les résultats, en particulier les tests DMS à l'échelle pilote, soutiennent le potentiel de haute valeur du projet de lithium de Yellowknife pour les sites miniers précoces et la production à long terme.

Li-FT Power (TSXV: LIFT) (OTCQX: LIFFF) berichtet über positive Ergebnisse aus metallurgischen Tests an acht Spodumenvorkommen im Lithiumprojekt Yellowknife in den Nordwest-Territorien, Kanada. Die Tests, durchgeführt von SGS Canada Inc., umfassten die Trennung durch schwere Flüssigkeiten, dichte Medien-Trennung (DMS) und Batch-Flotation.

Wesentliche Ergebnisse:

- Durchschnittlicher Spodumenkonzentratgrad: 5.83% Li2O

- Durchschnittliche globale Lithiumrückgewinnung: 79.1%

- Zweistufige DMS + Flotation: 81-89% Lithium-Rückgewinnung

- Einzelstufige DMS + Flotation: 61-72% Lithium-Rückgewinnung

CEO Francis MacDonald hob hervor, dass die Ergebnisse, insbesondere die DMS-Tests im Pilotmaßstab, das hohe Wertpotential des Lithiumprojekts Yellowknife für frühe Bergbaustellen und die langfristige Produktion unterstützen.

- High-quality spodumene concentrate averaging 5.83% Li2O

- Strong average global lithium recovery of 79.1%

- Two-stage DMS + flotation flowsheet achieved up to 89% lithium recovery

- Pilot-scale DMS testing indicates suitability for lower-cost separation methods

- Results support high-value potential for early mining sites and long-term production

- Single-stage DMS + flotation flowsheet showed lower lithium recovery (61-72%) compared to two-stage process

Insights

Analyzing...

VANCOUVER, British Columbia, Sept. 23, 2024 (GLOBE NEWSWIRE) -- Li-FT Power Ltd. (“LIFT” or the “Company”) (TSXV: LIFT) (OTCQX: LIFFF) (Frankfurt: WS0) is pleased to report results from the metallurgical sampling program completed in 2023 and 2024 across eight spodumene deposits within the Yellowknife Lithium Project, Northwest Territories, Canada. Metallurgical test work comprised of heavy liquid separation (HLS) testing, dense media separation (DMS) testing, and batch flotation testing was executed by SGS Canada Inc. (“SGS”) in Lakefield, Ontario. Testing was completed on samples from the Big East (BigE), Big West (BigW), Nite, Ki, Echo, Fi Main (FiM), Fi Southwest (FiSW), and Hi pegmatites.

Table 1- Summary of Results

| Sample | Flowsheet | Wt. | Assays (%) | Recovery (%) | |||

| (%) | Li | Li2O | Fe2O3 | Li | Fe2O3 | ||

| BigE | Two-stage DMS + Flotation | 21.1 | 2.7 | 5.79 | 0.76 | 87.4 | 29.3 |

| BigW | 11.1 | 2.67 | 5.75 | 0.76 | 81.4 | 16.0 | |

| Nite | 22.4 | 2.69 | 5.78 | 0.74 | 89.3 | 28.7 | |

| Ki | 18.4 | 2.8 | 6.02 | 0.58 | 84.8 | 22.8 | |

| Echo | 15.7 | 2.87 | 6.17 | 0.85 | 87.1 | 13.8 | |

| FiM | Single-stage DMS + Flotation | 15.8 | 2.6 | 5.59 | 0.49 | 60.8 | 14.7 |

| FiSW | 17.9 | 2.68 | 5.76 | 0.45 | 72.3 | 14.5 | |

| Hi | 16.7 | 2.69 | 5.77 | 0.46 | 70.1 | 14.6 | |

| 5.83 | 79.1 | ||||||

| Average Spodumene Concentrate Grade (Li2O %) | 5.83 | ||||||

| Average Global Lithium Recovery (%) | 79.1 | ||||||

Francis MacDonald, CEO of LIFT comments, “We are very pleased to report that the comprehensive metallurgical testing studies in preparation for our upcoming Preliminary Economic Assessment (PEA) yielded positive results. Studies notably included pilot-scale DMS testing that indicated that this lower-cost separation method is suitable for the spodumene-enriched pegmatite dikes that are targeted for the more accessible early mining sites that we envision could comprise lithium production in the district for a generation or more. As such the results of these important studies underpin the high value potential for our Yellowknife lithium project.”

Details of metallurgical program

Lithium chemical analysis of the metallurgical samples was performed by sodium peroxide fusion digestion followed by inductively coupled plasma optical spectroscopy (ICP-OES). Whole rock analysis (WRA) was performed by borate fusion and X-ray Fluorescence (XRF). Elemental compositions of the pegmatite samples are presented in Table 2. Pegmatite sample grades ranged from

Table 2: Chemical analysis of the metallurgical samples

| Component | Composition (%) | |||||||

| BigE | BigW | Nite | FiM | FiSW | HI | KI | Echo | |

| Li Li2O Fe2O3 SiO2 Al2O3 MgO CaO Na2O K2O MnO | 0.63 1.35 0.44 73.6 16.2 0.16 0.24 4.06 2.56 0.06 | 0.40 0.86 0.34 73.8 15.7 0.07 0.28 4.52 2.88 0.05 | 0.67 1.44 0.48 73.9 16.0 0.06 0.24 3.77 2.55 0.10 | 0.68 1.46 0.27 73.0 16.4 0.07 0.30 3.93 2.57 0.02 | 0.62 1.33 0.29 74.0 16.1 0.07 0.26 3.97 2.76 0.03 | 0.63 1.35 0.39 73.4 16.2 0.08 0.30 3.83 2.63 0.03 | 0.60 1.29 0.24 73.5 16.1 0.08 0.28 3.92 2.79 0.02 | 0.56 1.20 0.33 73.1 16.4 0.10 0.24 4.53 2.53 0.04 |

The mineralogical compositions of the metallurgical samples were determined using the semi-quantitative XRD and are shown in Table 2 . Spodumene concentrations in the pegmatites ranged from

Table 3 – Metallurgical sample mineralogy from semi-quantitative XRD. Only minor amounts of non-spodumene lithium-bearing minerals were found in samples with ~

| Mineral | Composition (%) | |||||||

| BigE | BigW | Nite | FiM | FiSW | Hi | Ki | Echo | |

| Spodumene | 17.9 | 11 | 18.3 | 17.8 | 17.3 | 17.2 | 13.0 | 14.6 |

| Albite | 36.5 | 38.9 | 34.2 | 33.3 | 34.6 | 34.7 | 34.0 | 40.4 |

| Quartz | 26.5 | 28.3 | 28.7 | 28.8 | 28.2 | 28.9 | 27.3 | 26.5 |

| Microcline | 12.8 | 15.7 | 13.1 | 10.3 | 13.7 | 12.3 | 13.0 | 11.6 |

| Muscovite | 4.9 | 4.5 | 4.1 | 7.8 | 5.2 | 5.4 | 6.0 | 5.4 |

| Fluorapatite | 0.6 | 0.7 | 1.1 | 0.5 | 0.5 | 0.8 | 0.9 | 0.8 |

| Triphylite | - | - | - | 1.0 | - | - | - | - |

| Beryl | 0.2 | 0.7 | 0.3 | 0.2 | 0.2 | 0.2 | 0.3 | 0.2 |

| Magnetite | 0.2 | 0.3 | 0.2 | 0.1 | 0.3 | 0.3 | 0.2 | 0.3 |

| Chlorite | 0.3 | - | - | 0.3 | - | 0.3 | - | - |

| Chlionochlore | - | - | - | - | - | - | 0.2 | - |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

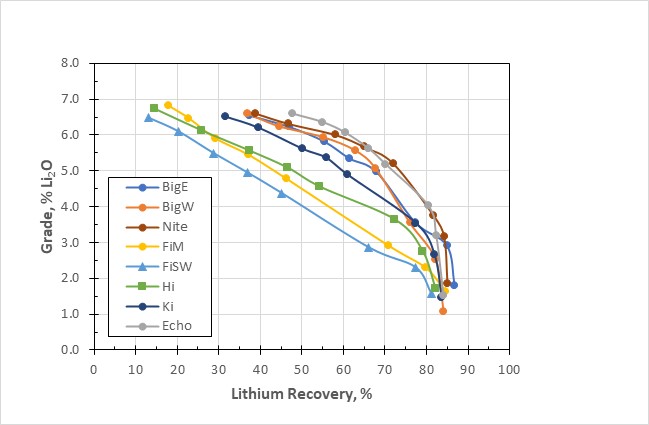

Heavy Liquid Separation (HLS) tests were performed on eight metallurgical samples. The samples were sourced from saw-cut channel samples on the surface of the various dykes. The samples were stage-crushed to a top crush size of 6.35 mm. The -6.35 mm +0.85 mm fraction was submitted for HLS testing which achieved global lithium recoveries ranging from

Figure 1 – HLS global lithium grade-recovery curves

Pilot-scale DMS was operated on each metallurgical sample. Two-stage DMS was undertaken on five of the samples (i.e., BigE, BigW, Nite, Ki, and Echo) and a single-stage DMS was operated on three of the samples (i.e., FIM, FiSW, and Hi).

For the two-stage DMS tests, global lithium recovery ranged from

Table 4 - Pilot-scale DMS test work results

| DMS | Sample | DMS Products | Wt. | Assays (%) | Recovery (%) | |||

| (%) | Li | Li2O | Fe2O3 | Li | Fe2O3 | |||

| Two-Stage DMS | BigE | Concentrate (Stage 2 Sinks) | 14.9 | 2.7 | 5.81 | 0.71 | 59.9 | 17.8 |

| BigW | 7.8 | 2.71 | 5.83 | 0.75 | 57.4 | 11.9 | ||

| Nite | 15.4 | 2.71 | 5.83 | 0.77 | 60.4 | 27.4 | ||

| Ki | 10.8 | 2.86 | 6.15 | 0.62 | 49.9 | 18.1 | ||

| Echo | 10.5 | 2.98 | 6.41 | 0.88 | 58.4 | 19.5 | ||

| Single-Stage DMS | FiM | Pre-Concentrate (Fines + Stage 1 Sinks) | 72 | 0.88 | 1.9 | 0.53 | 93 | 80.9 |

| FiSW | 68.1 | 0.9 | 1.94 | 0.54 | 95.1 | 76.7 | ||

| Hi | 66.8 | 0.94 | 2.02 | 0.55 | 95.2 | 77.9 | ||

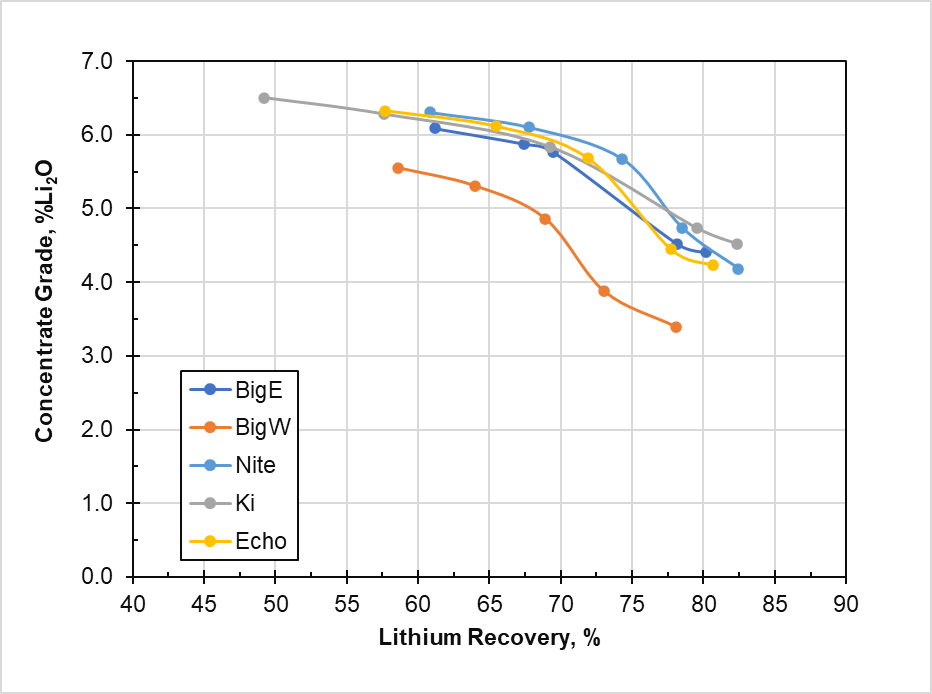

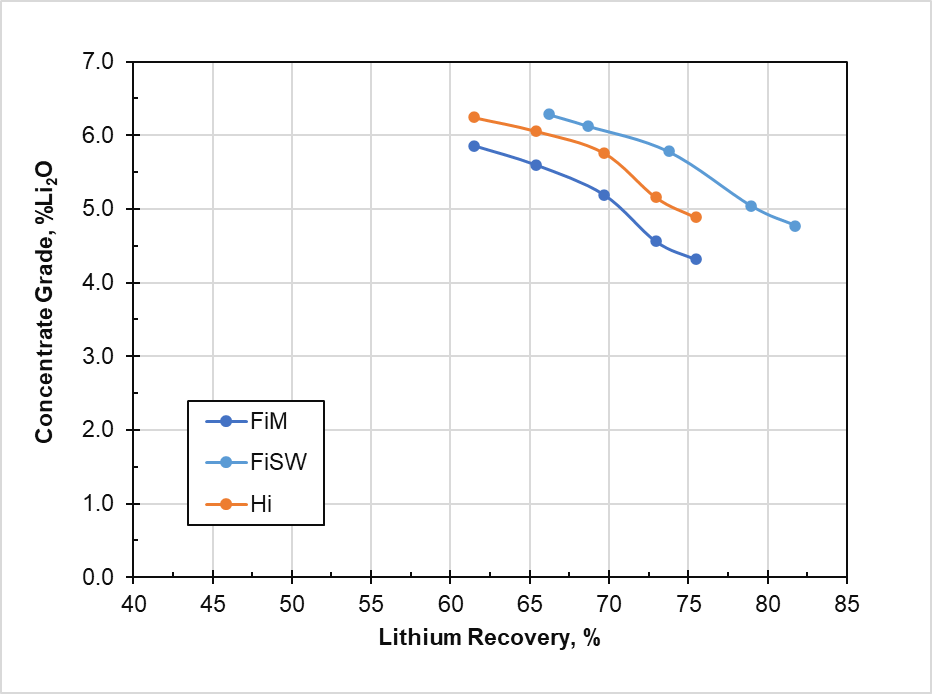

Three sets of flotation tests were performed on head samples or products from DMS operation (fines and DMS Stage 1 sinks or fines and Stage 2 DMS floats). For the flotation tests undertaken on the head samples, all samples produced roughly

Figure 2 - Flotation test results on DMS fines and stage 2 DMS floats

Figure 3 - Flotation test results on fines and DMS Stage 1 sinks

Overall laboratory lithium recoveries were calculated based on the DMS and batch flotation test results. Results for the two-stage DMS and flotation flowsheet produced combined concentrates ranging in grade from

Qualified Person

The disclosure in this news release of scientific and technical information regarding LIFT’s mineral properties has been reviewed and approved by Jarrett Quinn, Ph.D., P.Eng, Process Director, Synectiq Inc.., and a Qualified Person as defined by National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101) and member in good standing of the Ordre des Ingénieurs du Québec (OIQ) (Registration number: 5018119).

About LIFT

LIFT is a mineral exploration company engaged in the acquisition, exploration, and development of lithium pegmatite projects located in Canada. The Company’s flagship project is the Yellowknife Lithium Project located in Northwest Territories, Canada. LIFT also holds three early-stage exploration properties in Quebec, Canada with excellent potential for the discovery of buried lithium pegmatites, as well as the Cali Project in Northwest Territories within the Little Nahanni Pegmatite Group.

For further information, please contact:

| Francis MacDonald | Daniel Gordon |

| Chief Executive Officer | Investor Relations |

| Tel: + 1.604.609.6185 | Tel: +1.604.609.6185 |

| Email: info@li-ft.com | Email: investors@li-ft.com |

| Website: www.li-ft.com |

Cautionary Statement Regarding Forward-Looking Information

Certain statements included in this press release constitute forward-looking information or statements (collectively, “forward-looking statements”), including those identified by the expressions “anticipate”, “believe”, “plan”, “estimate”, “expect”, “intend”, “may”, “should” and similar expressions to the extent they relate to the Company or its management. The forward-looking statements are not historical facts but reflect current expectations regarding future results or events. This press release contains forward looking statements. These forward-looking statements and information reflect management's current beliefs and are based on assumptions made by and information currently available to the company with respect to the matter described in this new release.

Forward-looking statements involve risks and uncertainties, which are based on current expectations as of the date of this release and subject to known and unknown risks and uncertainties that could cause actual results to differ materially from those expressed or implied by such statements. Additional information about these assumptions and risks and uncertainties is contained under "Risk Factors and Uncertainties" in the Company's latest annual information form filed on March 27, 2024, which is available under the Company's SEDAR+ profile at www.sedarplus.ca, and in other filings that the Company has made and may make with applicable securities authorities in the future. Forward-looking statements contained herein are made only as to the date of this press release and we undertake no obligation to update or revise any forward-looking statements whether as a result of new information, future events or otherwise, except as required by law. We caution investors not to place considerable reliance on the forward-looking statements contained in this press release.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release.

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/e22bc7d8-c284-40ed-b583-bc099b2958f9

https://www.globenewswire.com/NewsRoom/AttachmentNg/b9d5e547-3b79-4248-9aca-387d7027eaca

https://www.globenewswire.com/NewsRoom/AttachmentNg/2af27c93-6478-40b2-8cb5-27a4f98de1db