CyberOptics to Showcase Metrology and Inspection Solutions at SEMICON China

CyberOptics Corporation (NASDAQ: CYBE) will showcase its WX3000™ metrology and inspection system featuring Multi-Reflection Suppression™ (MRS™) sensor technology at SEMICON China from March 17-19, 2021. The WX3000 provides sub-micrometer accuracy, enabling comprehensive inspection and metrology at speeds 2-3X faster than competitors. Additionally, the company will digitally present WaferSense® sensors that enhance semiconductor tool setup and maintenance. The developments reflect the growing demand for high-resolution semiconductor inspection technologies, as stated by CEO Dr. Subodh Kulkarni.

- WX3000 system offers sub-micrometer accuracy on features as small as 25µm.

- Achieves inspection speeds 2-3X faster than alternative technologies.

- Demonstrates high demand for precision metrology in semiconductor packaging.

- Economic uncertainties due to COVID-19 may impact revenue.

- Increased price competition could pressure product sales.

- Dependency on global supply chain may affect order fulfillment.

Insights

Analyzing...

CyberOptics® Corporation (NASDAQ: CYBE), a leading global developer and manufacturer of high-precision 3D sensing technology solutions, will feature the WX3000™ metrology and inspection system with Multi-Reflection Suppression™ (MRS™) sensor technology at SEMICON China, scheduled to take place March 17-19, 2021 at the Shanghai New International Expo Centre, hall N1, booth 1387 and 1325. The company also will demonstrate high-precision WaferSense® sensors for semiconductor tool setup and diagnostics.

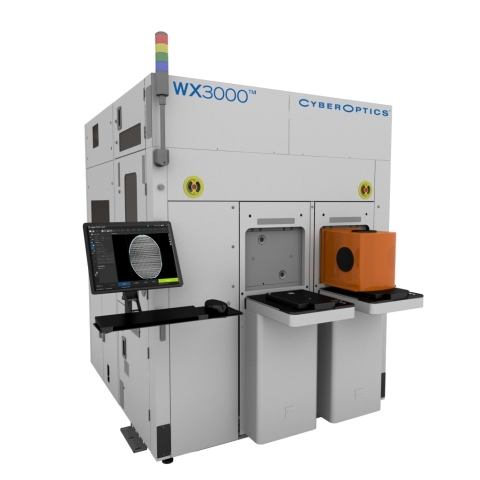

CyberOptics WX3000(TM) Inspection and Metrology System (Graphic: Business Wire)

The NanoResolution MRS sensor integrated into CyberOptics’ WX3000 system provides sub-micrometer accuracy on features as small as 25µm. While retaining its ability to reject spurious multiple reflections, it adds the ability to capture and analyze specular reflections from shiny surfaces of solder balls, bumps and pillars, allowing highly accurate inspection and 3D metrology of these critical packaging features. Complete 100 percent 3D/2D inspection and bump metrology can be accomplished 2-3X faster than alternative technologies delivering production-worthy throughput greater than 25 wafers (300mm) per hour.

“The need for high resolution, highly accurate, 100 percent inspection and metrology for wafer-level and advanced packaging continues to increase,” said Dr. Subodh Kulkarni, President and CEO, CyberOptics. “Not only does the WX3000 system provide these performance capabilities, but it provides the speed that alternative technologies lack.”

The company also will digitally demonstrate high-precision sensors that process and equipment engineers use in the front-end of the fab to speed equipment qualification, shorten equipment maintenance cycles, lower equipment expenses and optimize preventative maintenance plans. The WaferSense® Auto Resistance Sensor™ (ARS) enables real-time resistance measurements of plating cell contacts in semiconductor Electrochemical Deposition (ECD) applications, and the In-Line Particle Sensor™ (IPS) detects, monitors and enables troubleshooting of particles down to 0.1 µm in gas and vacuum lines in any areas of the fab 24/7.

For more information, visit www.cyberoptics.com.

About CyberOptics

CyberOptics Corporation (www.cyberoptics.com) is a leading global developer and manufacturer of high-precision 3D sensing technology solutions. CyberOptics’ sensors are used for inspection and metrology in the SMT and semiconductor markets to significantly improve yields and productivity. By leveraging its leading edge technologies, the Company has strategically established itself as a global leader in high precision 3D sensors, allowing CyberOptics to further increase its penetration of key vertical markets. Headquartered in Minneapolis, Minnesota, CyberOptics conducts worldwide operations through its facilities in North America, Asia and Europe.

Statements regarding the Company’s anticipated performance are forward-looking and therefore involve risks and uncertainties, including but not limited to: a possible world-wide recession or depression resulting from the economic consequences of the COVID-19 pandemic; the negative effect on our revenue and operating results of the COVID-19 crisis on our customers and suppliers and the global supply chain; market conditions in the global SMT and semiconductor capital equipment industries; trade relations between the United States and China and other countries; the timing of orders and shipments of our products, particularly our 3D MRS SQ3000 Multi-Function systems and MX systems for memory module inspection; increasing price competition and price pressure on our product sales, particularly our SMT systems; the level of orders from our OEM customers; the availability of parts required to meet customer orders; unanticipated product development challenges; the effect of world events on our sales, the majority of which are from foreign customers; rapid changes in technology in the electronics and semiconductor markets; product introductions and pricing by our competitors; the success of our 3D technology initiatives; the market acceptance of our SQ3000 Multi-Function inspection and measurement systems and products for semiconductor advanced packaging inspection and metrology; costly and time consuming litigation with third parties related to intellectual property infringement; the negative impact on our customers and suppliers due to past and future terrorist threats and attacks and any acts of war; the impact of the MX3000 orders on our consolidated gross margin percentage in any future period; risks related to cancellation or renegotiation of orders we have received; and other factors set forth in the Company’s filings with the Securities and Exchange Commission.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210311005346/en/