Commerce Resources Announces Significant Advancements and Simplification of the Ashram Deposit’s Process Flowsheet

- Significant advancements in mineral processing and hydrometallurgical flowsheets for the Ashram Deposit.

- Achievement of a simplification and optimization of the front-end mineral processing flowsheet.

- Production of high-grade monazite concentrates with strong recovery rates.

- Development of a streamlined hydrometallurgical flowsheet with impressive recovery rates for rare earth elements.

- Potential for significant cost reductions and increased efficiency in processing operations.

- None.

Insights

Analyzing...

VANCOUVER, BC / ACCESSWIRE / March 4, 2024 / Commerce Resources Corp. (TSXV:CCE)(FSE:D7H0)(OTCQX:CMRZF) (the "Company" or "Commerce") is pleased to announce that it has made significant advancements in the mineral processing and hydrometallurgical flowsheets for the Ashram Rare Earth and Fluorspar Deposit (the "Ashram Deposit"). The Ashram Deposit, wholly owned by the Company and located in Quebec, Canada, is one of the largest undeveloped monazite dominant rare earth deposits in the world. This rare earth mineralogy results in significant NdPr distributions (>

The Company is pleased to report a significant simplification and optimization of the Ashram Deposit's front-end mineral processing flowsheet whereby 30-35+% REO monazite mineral concentrates at strong recovery (between 60

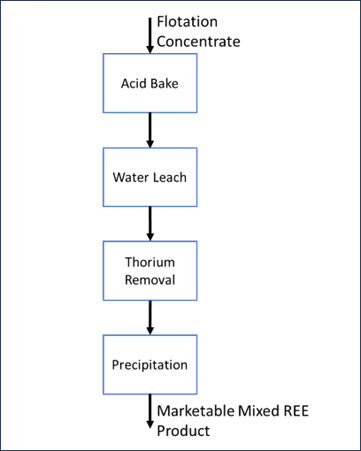

In addition to the mineral processing developments, a streamlined hydrometallurgical flowsheet has also been developed and demonstrated at bench scale for the downstream processing of the monazite flotation concentrate produced by SGS. The hydrometallurgical flowsheet uses a standard acid bake - water leach process followed by thorium removal and direct rare earth element ("REE") precipitation (Figure 1). This downstream testwork has been carried out by Trois-Rivieres-based L3 Process Development ("L3").

Company President Chris Grove states "We are very excited by these results confirming our expectations of positive beneficiation from our Ashram Deposit with its very attractive mineralogy and geology. We look forward to announcing additional developments as we continue to advance this excellent asset."

This streamlined hydrometallurgical flowsheet developed and demonstrated by L3 on the SGS monazite concentrates achieved an overall recovery into solution for NdPr above

The Ashram Deposit ranks as one of the largest REE deposits globally, consisting of a monazite dominated, single mineralized body outcropping at surface, and has a footprint approximately 700 m along strike, over 300 m across, and 600 m deep, remaining open in several directions. Therefore, the deposit is envisioned to be an open-pit extraction operation at production, with a very low strip ratio. Coupled with a monazite rare earth mineralogy and strong NdPr distributions, these attributes allow for the company to have significant flexibility in flowsheet design, whereby a 60+% overall recovery of the NdPr into saleable product is significant. The new mineral processing flowsheet will permit an operator to leverage the size of the deposit and optimize mining for effective recovery into a high-grade monazite concentrate in order to significantly simplify and thereby reduce project mineral processing and downstream hydromet CAPEX and OPEX.

Figure 1: Simplified block diagram of the downstream hydrometallurgical flowsheet developed by L3 for the monazite concentrates produced at SGS Canada.

About the Ashram Deposit

The Ashram Deposit ranks as one of the largest REE (and fluorspar) deposits globally, consisting of a monazite dominated, single mineralized body outcropping at surface, and has a footprint approximately 700 m along strike, over 300 m across, and 600 m deep, remaining open in several directions. The deposit hosts a measured resource of 1.6 million tonnes (Mt) at

NI 43-101 Disclosure

Jordan Zampini, P.Eng., Process Manager - Montreal for DRA Americas Inc., a Qualified Person as defined by National Instrument 43-101, has reviewed and approved the technical information, and verified the data, contained in this news release.

Tommee Larochelle, Ing., PE, MBA, PhD. Chief Technology Officer, Co-Owner, L3 Process Development, a Qualified Person as defined by National Instrument 43-101, has reviewed and approved the technical information, and verified the data, contained in this news release.

About Commerce Resources Corp.

Commerce Resources Corp. is a junior mineral resource company focused on the development of the Ashram Rare Earth and Fluorspar Deposit located in Quebec, Canada. The Company is positioned to become one of the lowest cost rare earth producers globally, with a specific focus on being a long-term supplier of mixed rare earth carbonate and/or NdPr oxide to the global market. The Ashram Deposit is characterized by simple rare earth (monazite, bastnaesite, xenotime) and gangue (carbonates) mineralogy, a large tonnage resource at favourable grade, and has demonstrated the production of high-grade (>

For more information, please visit the corporate website at www.commerceresources.com or email info@commerceresources.com.

On Behalf of the Board of Directors

COMMERCE RESOURCES CORP.

"Chris Grove"

Chris Grove

CEO and President

Tel: 604.484.2700

Email: cgrove@commerceresources.com

Web: http://www.commerceresources.com

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Forward Looking Statements

This news release contains forward-looking statements, which includes any information about activities, events or developments that the Company believes, expects or anticipates will or may occur in the future. Forward looking statements in this news release include that that mixed REC is readily saleable; that partial separation of REEs will allow for the marketability of individual elements to be produced; that Ashram has the potential to become one of the largest fluorspar deposit and a long-term supplier to the met-spar and acid-spar markets; and that the Company is positioning to be one of the lowest cost rare earth element producers globally. These forward-looking statements are subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information. Risks that could change or prevent these events, activities or developments from coming to fruition include: that we may not be able to fully finance any additional exploration on the Ashram Project; that even if we are able raise capital, costs for exploration activities may increase such that we may not have sufficient funds to pay for such exploration or processing activities; the timing and content of any future work programs; geological interpretations based on drilling that may change with more detailed information; potential process methods and mineral recoveries assumptions based on limited test work and by comparison to what are considered analogous deposits that, with further test work, may not be comparable; testing of our process may not prove successful or samples derived from the Ashram Project may not yield positive results, and even if such tests are successful or initial sample results are positive, the economic and other outcomes may not be as expected; the availability of labour and equipment to undertake future exploration work and testing activities; geopolitical risks which may result in market and economic instability; and despite the current expected viability of the Ashram Project, conditions changing such that even if metals or minerals are discovered on the Ashram Project, the project may not be commercially viable; The forward-looking statements contained in this news release are made as of the date hereof and the Company assumes no responsibility to update or revise such information to reflect new events or circumstances, except as required by law.

SOURCE: Commerce Resources Corp.

View the original press release on accesswire.com