Gratomic Announces Engineering Update for Its Flagship Aukam Project in Namibia

Gratomic (OTCQX:CBULF) has disclosed successful results from its wet circuit process flow tests conducted by SGS Lakefield. The tests achieved a concentrate grading up to 97.3% total carbon (C(t)), with high recoveries between 86.7% and 87.5%. The company anticipates an increase in recovery rates to 94-95% in a closed circuit operation. Gratomic is also finalizing steps to enhance purity for battery applications. However, no feasibility studies have been completed, raising risks regarding production viability and economic feasibility for the Aukam project.

- Achieved concentrate grades between 94.8% and 97.3% C(t).

- High total carbon recoveries ranging from 86.7% to 87.5%.

- Expected recovery rate increase to 94-95% in closed circuit operation.

- Plans to reach purity levels of up to 99.7% Cg without harsh chemicals.

- No Preliminary Economic Analysis, Preliminary Feasibility Study, or feasibility study completed.

- Increased uncertainty regarding mineral recovery and production costs.

- Higher risk of economic and technical failure due to lack of mineral resources and reserves.

Insights

Analyzing...

TORONTO, ON / ACCESSWIRE / December 20, 2021 / Gratomic Inc. ("Gratomic," "GRAT" or the "Company") (TSXV:GRAT)(OTCQX:CBULF)(FSE:CB82) announces the results for the wet circuit process flow, independently performed by SGS Lakefield.

Open circuit cleaner flotation tests have been carried out to produce a minimum concentrate grading of

Following to the wet circuit development, the Company is finalizing the tests and simulations in order to add dry air classification steps at different stages of the circuit, aiming to reach purity levels required for the battery anode applications without the use of harsh chemical processes, such as acid leaching. To date, Gratomic has sent samples for independent verification through Ortech, resulting in grades of up to

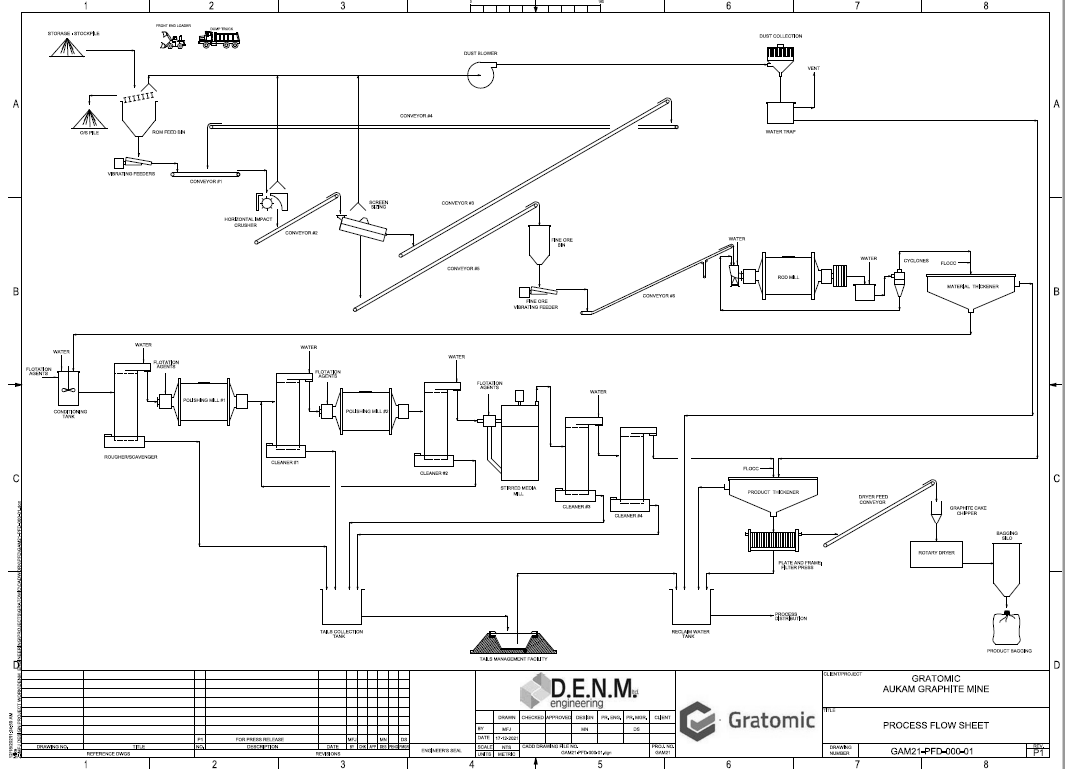

The process flow diagram below, prepared by D.E.N.M. Engineering, represents the expected final configuration for the wet circuit section in Aukam's onsite graphite processing plant:

The Company has completed assembly on the processing circuit, the installation of 3 additional polishing mills and bagging units will complement the existing circuit.

Armando Farhate, COO & Head of Graphite Marketing and Sales, says: "These results are aligned with our initial expectations that the Aukam material would have a world-class performance at the concentration circuit, and will be a valuable tool in order to bring the Aukam project into production phase in the near future"

"There has been a tremendous amount of internal work conducted on the Aukam Graphite Project from the very beginning to better understand the asset, which has demonstrated profound potential at every stage. We are very pleased with the results demonstrated by the independent performance testing and look forward to what will transpire at Aukam in 2022," stated Arno Brand, President & CEO.

Gratomic wishes to emphasize that no Preliminary Economic Analysis, Preliminary Feasibility Study or Feasibility Study has been completed to support any level of production. In fact, no mineral resources let alone mineral reserves demonstrating economic viability and technical feasibility, have been delineated on the Aukam property.

The Company is working towards completing a Preliminary Feasibility Study (PFS) on the Aukam Processing plant. The study, its recommendations, and their subsequent implementation, will provide conclusions and recommendation at a PFS level of comfort relating to the scale up of the existing processing plant to a commercial scale processing facility capable of producing the desired concentrate grades and production rates.

Gratomic wishes to emphasize that the supply of graphite is conditional on Gratomic being able to bring the Aukam project into a production phase, and for any graphite being produced to meet certain technical and mineralization requirements. Gratomic continues to move its business towards production and as part of its business plan, expects to file a National Instrument 43-101 Standards of Disclosure for Mineral Projects resource estimate in Q1 2022.

Risk Factors

No mineral resources, let alone mineral reserves demonstrating economic viability and technical feasibility, have been delineated on the Aukam Property. The Company is not in a position to demonstrate or disclose any capital and/or operating costs that may be associated with the processing plant until the PFS is completed.

The Company advises that it has not based its production decision on even the existence of mineral resources let alone on a PFS or feasibility study of mineral reserves, demonstrating economic and technical viability, and, as a result, there may be an increased uncertainty of achieving any particular level of recovery of minerals or the cost of such recovery, including increased risks associated with developing a commercially mineable deposit.

Historically, such projects have a much higher risk of economic and technical failure. There is no guarantee that production will begin as anticipated or at all or that anticipated production costs will be achieved.

Failure to commence production would have a material adverse impact on the Company's ability to generate revenue and cash flow to fund operations. Failure to achieve the anticipated production costs would have a material adverse impact on the Company's cash flow and future profitability.

Steve Gray, P. Geo., a consultant to the Company has reviewed and approved the scientific and technical information in this press release and is the Company's "Qualified Person" as defined by National Instrument 43-101 - Standards of Disclosure for Mineral Projects.

About Gratomic Inc.

Gratomic is focused on introducing an exceptional anode material to the global electric vehicle and energy storage supply chains. True to its roots as an exploration and mining company, Gratomic aims to achieve full operational capabilities in 2022 on its Aukam Graphite Project and continues to diversify its assets into a multi-national company with various projects globally. Large quantities of its naturally high-quality vein graphite have been shipped for testing to confirm its viability as an anode material. Gratomic is confident that the results will provide a unique competitive advantage in its desired target markets.

The Company's recent collaboration agreement with Forge Nano has advanced the developments on its graphite finalization phase for the micronization, spheronization, and the patented ALD coating of its Aukam vein graphite for use in lithium-ion batteries. Forge Nano is a global leader in surface engineering and precision nano-coating technology, using Atomic Layer Deposition.

GRAT has two outstanding off-take purchase agreements with TODAQ and Phu Sumika with contract fulfillment slated to begin in 2022. Gratomic plans to deliver mine-to-market traceability through its partnership with deeptech company TODAQ by providing documented tracking on all graphite generated at its flagship Aukam Graphite Project.

For more information: visit the website at www.gratomic.ca or contact:

Arno Brand at abrand@gratomic.ca or 416 561-4095

Subscribe at gratomic.ca/contact/ to be added to our email list.

"Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release."

Forward-Looking Statements:

This news release contains forward-looking statements, which relate to future events or future performance and reflect management's current expectations and assumptions. Such forward-looking statements reflect management's current beliefs and are based on assumptions made by and information currently available to the Company. Investors are cautioned that these forward-looking statements are neither promises nor guarantees and are subject to risks and uncertainties that may cause future results to differ materially from those expected. These forward-looking statements are made as of the date hereof and, except as required under applicable securities legislation, the Company does not assume any obligation to update or revise them to reflect new events or circumstances. All of the forward-looking statements made in this press release are qualified by these cautionary statements and by those made in our filings with SEDAR in Canada (available at www.sedar.com)

SOURCE: Gratomic Inc.

View source version on accesswire.com:

https://www.accesswire.com/678758/Gratomic-Announces-Engineering-Update-for-Its-Flagship-Aukam-Project-in-Namibia