Canada Carbon Completes Bulk Sample Program on Its Asbury Graphite Project

Canada Carbon has completed its Bulk Sample Program at the Asbury Graphite Project in Quebec. Working with SGS Lakefield, the program analyzed head assays, Bond Ball Work Index, and flowsheet optimization. The composite drill core samples showed 3.68% graphitic carbon, exceeding the Initial Resource Estimate. The final flotation test achieved combined concentrate grades of >98% total carbon, with +150 mesh and +325 mesh assaying at 99.1% and 99.0% respectively. The optimized flowsheet demonstrated efficient primary processing operation suitable for battery anode applications. The company aims to complete the Pre-Feasibility Study by Q1 2025.

Canada Carbon ha completato il suo Programma di Campionamento di Massa presso il Progetto Grafite Asbury in Quebec. Lavorando con SGS Lakefield, il programma ha analizzato le prove di testa, l'Indice di Lavoro Bond Ball e l'ottimizzazione del flusso di lavoro. I campioni compositi del nucleo di perforazione hanno mostrato 3,68% di carbonio grafitico, superando la Stima Iniziale delle Risorse. Il test finale di flottazione ha raggiunto gradi combinati di concentrazione di oltre il 98% di carbonio totale, con mesh +150 e +325 che hanno mostrato valori rispettivamente del 99,1% e 99,0%. Il flusso di lavoro ottimizzato ha dimostrato un'operazione di lavorazione primaria efficiente adatta per le applicazioni degli anodiche per batterie. L'azienda ha come obiettivo di completare lo Studio di Pre-Fattibilità entro il primo trimestre del 2025.

Canada Carbon ha completado su Programa de Muestras a Granel en el Proyecto de Grafito Asbury en Quebec. Trabajando con SGS Lakefield, el programa analizó los ensayos de cabeza, el Índice de Trabajo Bond Ball, y la optimización del flujo. Las muestras compuestas del núcleo de perforación mostraron 3.68% de carbono grafítico, superando la Estimación Inicial de Recursos. La prueba final de flotación alcanzó grados de concentración combinados de más del 98% de carbono total, con malla +150 y +325 que presentaron ensayos de 99.1% y 99.0% respectivamente. El flujo optimizado demostró una operación de procesamiento primario eficiente adecuada para aplicaciones de ánodos de baterías. La empresa aspira a completar el Estudio de Pre-Factibilidad para el primer trimestre de 2025.

캐나다 탄소는 퀘벡의 아스버리 흑연 프로젝트에서 대량 샘플 프로그램을 완료했습니다. SGS 레이크필드와 협력하여 이 프로그램은 헤드 assay, 본드 볼 작업 지수 및 공정 최적화를 분석했습니다. 복합 드릴 코어 샘플은 3.68%의 흑연 카본을 보여 초기 자원 추정치를 초과했습니다. 최종 플로테이션 테스트는 총 탄소 98% 이상의 농축도를 달성했으며, +150 메쉬 및 +325 메쉬는 각각 99.1%와 99.0%로 분석되었습니다. 최적화된 공정 흐름은 배터리 음극 응용에 적합한 효율적인 1차 가공 작업을 보여주었습니다. 이 회사는 2025년 1분기까지 사전 타당성 연구를 완료할 계획입니다.

Canada Carbon a terminé son Programme d’échantillonnage en vrac au Projet de Graphite Asbury au Québec. En collaboration avec SGS Lakefield, le programme a analysé les échantillons de tête, l'Indice de Travail Bond Ball et l'optimisation du flux de traitement. Les échantillons de carottes de forage composites ont montré 3.68% de carbone graphitique, dépassant l'estimation initiale des ressources. Le test final de flottation a atteint des grades de concentré combinés de plus de 98% de carbone total, avec des tamisages +150 et +325 affichant respectivement 99,1% et 99,0%. Le flux de traitement optimisé a démontré une opération de traitement primaire efficace adaptée aux applications des anodes de batterie. L'entreprise vise à terminer l'étude de faisabilité préalable d'ici le premier trimestre 2025.

Canada Carbon hat sein Programm zur Entnahme von Großproben im Asbury-Graphitprojekt in Quebec abgeschlossen. In Zusammenarbeit mit SGS Lakefield analysierte das Programm Head-Assays, den Bond Ball Work Index und die Flussdiagrammoptimierung. Die kompositen Bohrkernproben wiesen 3,68% graphitischen Kohlenstoff auf, was die erste Ressourcenschätzung überstieg. Der abschließende Flotationsversuch erreichte kombinierte Konzentratsgehalte von über 98% Gesamtcarbon, wobei +150 Mesh und +325 Mesh 99,1% bzw. 99,0% aufwiesen. Das optimierte Flussdiagramm zeigte einen effizienten primären Verarbeitungsbetrieb, der für Anwendungen in Batterien geeignet ist. Das Unternehmen beabsichtigt, die Machbarkeitsstudie bis zum 1. Quartal 2025 abzuschließen.

- Achieved high-grade concentrate results exceeding 98% total carbon

- Core samples showed 3.68% graphitic carbon, above initial resource estimates

- +150 mesh and +325 mesh samples achieved 99.1% and 99.0% total carbon respectively

- Optimized flowsheet demonstrates efficient primary processing operation

- Increased primary grinding eliminates +48 mesh flake from concentrate profile

TORONTO, Oct. 24, 2024 (GLOBE NEWSWIRE) -- Canada Carbon Inc. (the “Company”) (TSX-V:CCB), (FF:U7N1) reports that it has completed the Bulk Sample Program for its

- Head assays

- Bond Ball Work Index Analysis

- Flowsheet optimization

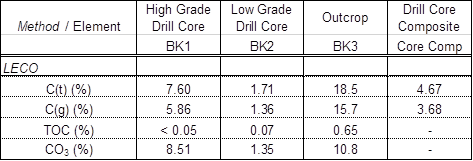

Head Assays

As previously reported (see Press Release dated August 8th, 2024), the Company provided three ore samples for the program : BK1 – high grade drill core, BK2 – low grade drill core, and BK3 – a high grade outcrop. These samples were prepared for testing, and a composite of the two drill core samples (BK1 and BK2) was prepared and named Core Comp. The Company believe that the Core Comp will be a fairly representative sample of the overall Asbury deposit.

Carbon speciation analyses of these samples shows graphitic carbon (C(g)) ranging from

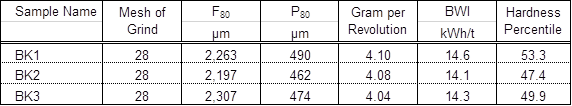

Bond Ball Work Index Analysis

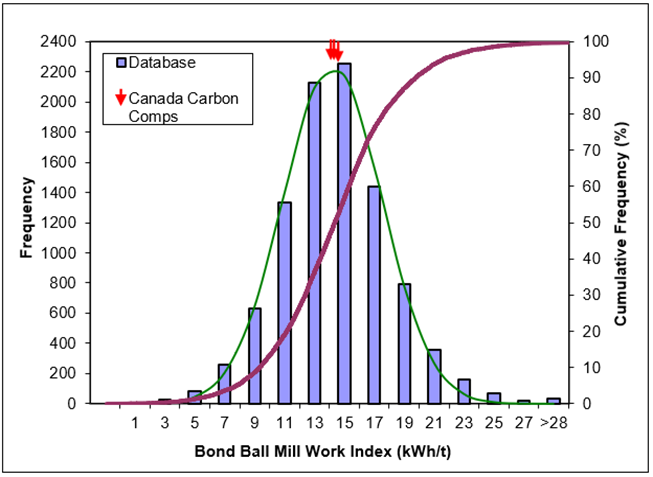

Bond Ball Work Index testing was conducted on the three samples, BK1, BK2 and BK3 which produced similar work indices ranging from 14.1 (BK2) to 14.6 (BK1). In comparison with SGS’s database of thousands of ore types, shown in the graph below, the Asbury samples fall in the median range of hardness percentile, ranging from

Note: F80 denotes feed size (in microns), while P80 denotes product size (i.e – measurement at which

Flowsheet Optimization

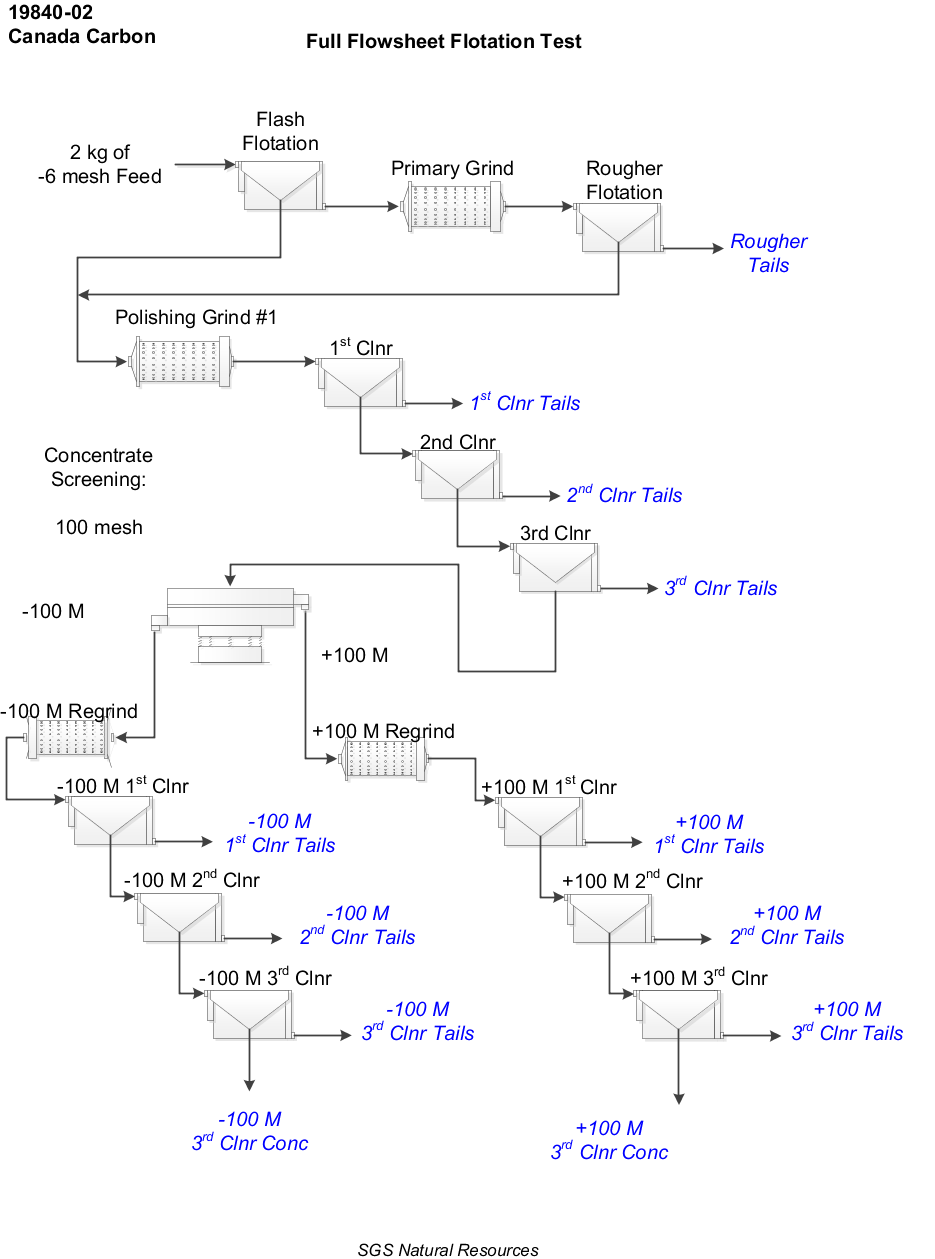

As the figure below indicates, the Company and SGS engaged in a very thorough process of developing and optimizing the evaluate tradeoffs between flake size and purity based on the length of primary and secondary grind cycles and the number of rougher columns or cells through which the concentrate will be cycled. Global operating parameters utilized in the optimized flowsheet are as follows:

| Primary Grind: | 18 minutes in 2 kg rod mill @ |

| Polishing Grind of Combination Flash & Rougher (Ro) Concentrate: | 15 minutes @ ~ |

| +100 M Regrind: | 10 minutes @ ~ |

| -100 M Regrind: | 20 minutes @ ~ |

Note: SMM – Stirred Media Mill

In the optimized flowsheet a flash flotation stage was conducted on the crushed ore producing flash rougher concentrates. The flash rougher tailings were ground and a rougher concentrate produced. Two regrind circuits were added down-process from a 100-mesh concentrate screen. The flowsheet then provides for three cleaner columns to follow each of the +100 and -100 mesh lines.

While the company was initially focused on minimizing required grinding power, as well as the potential for preservation of coarse-flake graphite, subsequent testing shows that increased primary grinding eliminates +48 mesh flake from the concentrate profile but results in significant gains in purity. Given the focus on future participation in the battery anode supply chain, producing a higher purity concentrate, which would be easier and cheaper to purify, is ideal for the Company and its potential future clients.

Floatation Tests Results

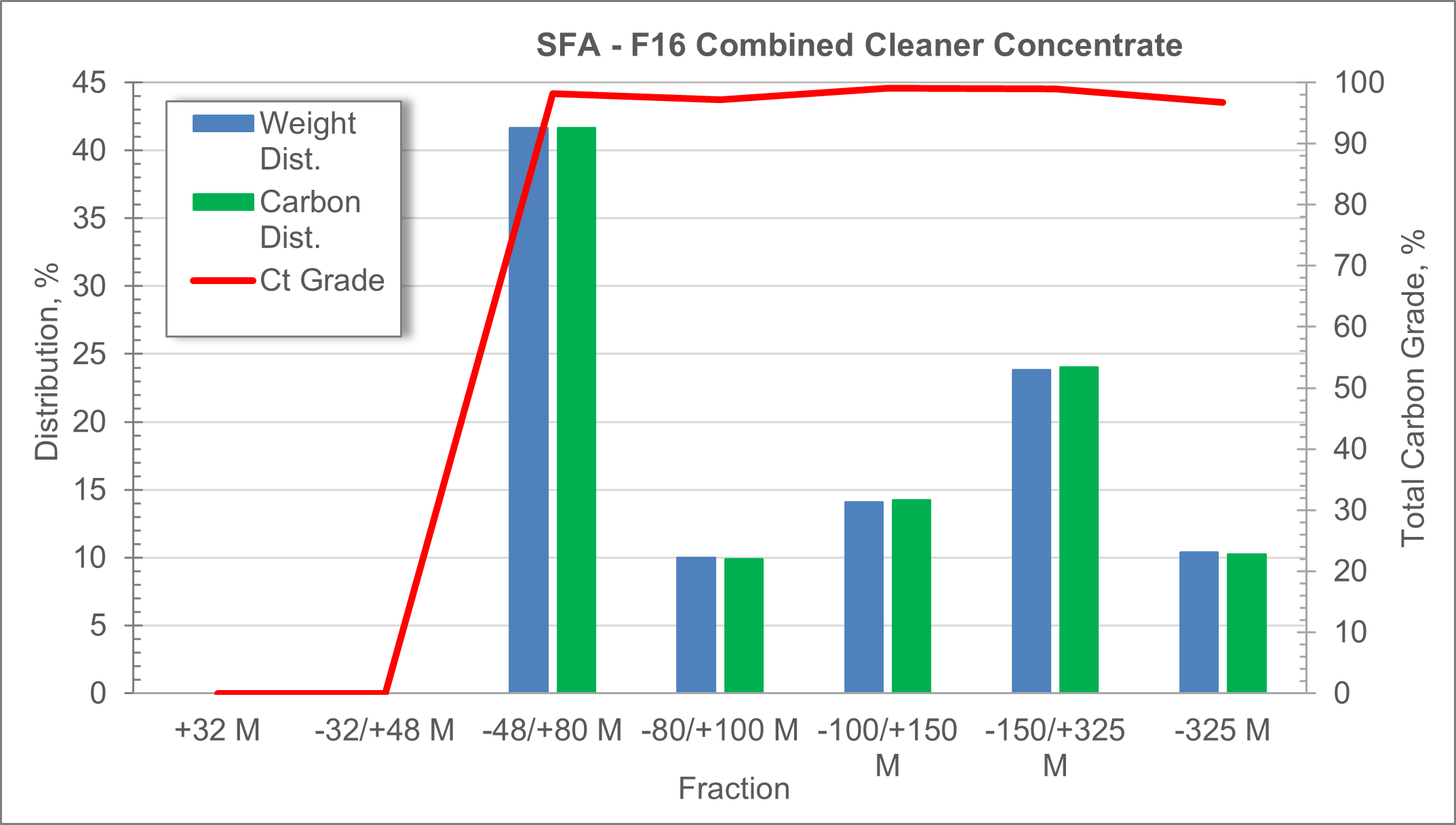

The Company’s final floatation test achieved combined concentrate grades of greater than

- Primary grind time was increased first from 12 minutes to 15 minutes and then from 12 minutes to 18 minutes.

- The 15-minute primary grind resulted in P80 230 µm, while the 18-minute primary grind resulted in P80 214 µm. However, it was determined that grinding to P80 214 µm is not required.

- Because of the finer primary grind, the +100 M concentrate exceeded our target

95% C(t) grade after screening (achieving96.2% C(t)) and may not need cleaner stages at all. - The -100 M concentrate, after secondary grinding, achieved a

95.2% C(t) grade after the 1st -100 M cleaner, suggesting that the remaining two cleaner stages provided for in the work sheet may not be necessary at all. - It was also critical to note that, in the final floatation test, the Company’s +150 mesh and the +325 mesh assayed out at

99.1% and99.0% C(t) respectively.

Note: In concentrate samples C(t) is assumed equal to C(g) as any carbonates are expected to flow to the tailings.

"The completion of our Bulk Sample Program by SGS Lakefield produced results beyond our expectations. We were able to demonstrate that a composite sample of our ore recorded in-situ grades in excess of the average in our Initial resource estimate. Additionally, we have engineered a flowsheet which produces high Ct concentrate from an efficient primary processing operation. This will allow us to market an anode market product which will be significantly easier and more cost effective to purify. These characteristics are certainly important to the battery anode space, but also attractive across a variety of high margin applications. We intend to ensure that this scalable, exceptional deposit is expeditiously developed and properly positioned to maximize shareholder value." declared Ellerton Castor, CEO of Canada Carbon.

Next Steps

With the Bulk Sample program complete, Canada Carbon will target completion of the Asbury Pre-Feasibility Study by the end of Q1, 2025. Additionally, the results will allow CCB to conduct battery cell testing on the concentrate through Polaris Labs. Finally, the Company will also expand its scope of lab testing to begin qualifying the Asbury concentrate for a variety of additional industry verticals.

Qualified Person

This press release was prepared by Rick Keevil, who is an independent qualified persons as defined under National Instrument 43-101, and who reviewed and approved the geological information provided in this news release.

Asbury Project Overview

The

CANADA CARBON INC.

“Ellerton Castor”

Chief Executive Officer and Director

Contact Information

E-mail inquiries: info@canadacarbon.com

P: (905) 407-1212

FORWARD LOOKING INFORMATION

This press release contains statements that constitute “forward-looking information” (“forward-looking information”) within the meaning of the applicable Canadian securities legislation. All statements, other than statements of historical fact, are forward-looking information and are based on expectations, estimates and projections as at the date of this press release. Any statement that discusses predictions, expectations, beliefs, plans, projections, objectives, assumptions, future events or performance (often but not always using phrases such as “expects”, or “does not expect”, “is expected”, “anticipates” or “does not anticipate”, “plans”, “budget”, “scheduled”, “forecasts”, “estimates”, “believes” or “intends” or variations of such words and phrases or stating that certain actions, events or results “may” or “could”, “would”, “might” or “will” be taken to occur or be achieved) are not statements of historical fact and may be forward-looking information. Forward-looking information in this press release includes statements regarding the development of the Company’s Asbury deposit and financing thereof, the entering of the joint venture with Irondequoit Offering, future production from the Company’s Asbury deposit, sales agreements and other matters related thereto. In disclosing the forward-looking information contained in this press release, the Company has made certain assumptions. Although the Company believes that the expectations reflected in such forward-looking information are reasonable, it can give no assurance that the expectations of any forward-looking information will prove to be correct. Known and unknown risks, uncertainties, and other factors which may cause the actual results and future events to differ materially from those expressed or implied by such forward-looking information. Such factors include but are not limited to: compliance with extensive government regulations; financial abilities; the ability to develop the Asbury deposit; domestic and foreign laws and regulations adversely affecting the Company’s business and results of operations; the impact of COVID-19; and general business, economic, competitive, political, and social uncertainties. Accordingly, readers should not place undue reliance on the forward-looking information contained in this press release. Except as required by law, the Company disclaims any intention and assumes no obligation to update or revise any forward-looking information to reflect actual results, whether as a result of new information, future events, changes in assumptions, changes in factors affecting such forward-looking information or otherwise.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/4dc9a801-52c4-495b-b2b8-2a016eb54af5

https://www.globenewswire.com/NewsRoom/AttachmentNg/7686b368-e16b-4513-847d-07088292324e

https://www.globenewswire.com/NewsRoom/AttachmentNg/a55474fd-6525-4dc9-ac7f-f03595147def

https://www.globenewswire.com/NewsRoom/AttachmentNg/caa5894e-5108-469c-85f7-6178fbda823f

https://www.globenewswire.com/NewsRoom/AttachmentNg/275847c9-41d0-48c6-9a36-e9d465c98a3e

https://www.globenewswire.com/NewsRoom/AttachmentNg/868aa323-51b7-402b-8aa9-38efe9faf589

FAQ

What were the key results of Canada Carbon's (BRUZF) Asbury Graphite Project bulk sample program?

When will Canada Carbon (BRUZF) complete the Asbury Pre-Feasibility Study?